Culture method for increasing yield of fucoxanthin contained in diatom

A medium fucoxanthin and culture method technology, applied in the field of diatom culture and fucoxanthin yield culture, can solve the problems of low fucoxanthin content and unsatisfactory fucoxanthin yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

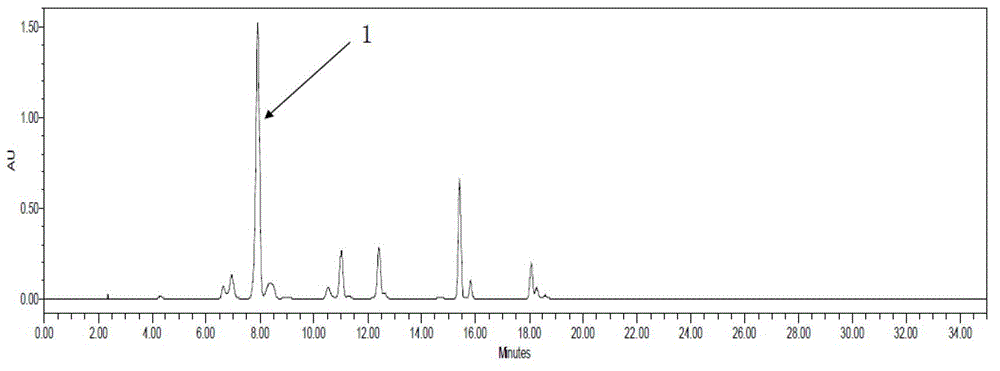

Image

Examples

Embodiment 1

[0047] Cultivate Cyclotella as follows:

[0048] (1) Use a 250ml Erlenmeyer flask as the culture container, with a working volume of 120ml. The activated Cyclotella was cultured heterotrophically in a shake flask, and the Cyclotella seed solution in the logarithmic growth phase was obtained after 7 days;

[0049] (2) Inoculate 10% (v / v) inoculum into newly prepared medium I for heterotrophic culture in shake flasks, and the initial biomass concentration converted to dry weight is 0.2±0.01g / L. Place the Erlenmeyer flask in a dark temperature-controlled shaker, the shaker speed is 130rpm, the temperature is controlled at 27±1°C, and the culture time is 8 days (192 hours). Samples were collected on the 6th, 7th, and 8th day of heterotrophic culture, washed by centrifugation, freeze-dried, and the content of fucoxanthin in the algae powder was tested. Among them, the formula of medium Ⅰ is: 0.66g MgSO dissolved in 1L saline 4 ·7H 2 O, 0.3g urea, 50.5mg KH 2 PO 4 , 34mg H 3 ...

Embodiment 2~5

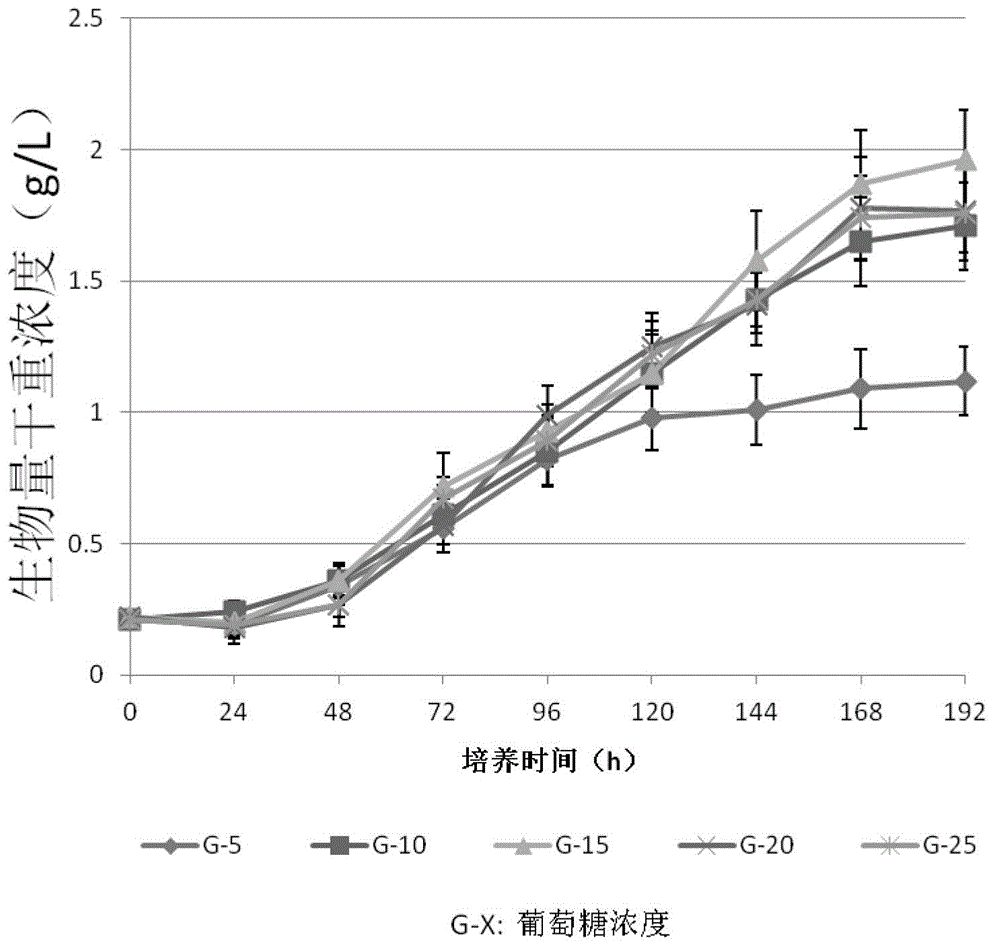

[0055] Embodiments 2 to 5 are basically the same as in Example 1, except that the glucose concentration in the medium I used in step 2 is different, and the glucose concentrations in Examples 2 to 5 are respectively 10g / L, 15g / L, and 20g / L and 25g / L.

[0056] Embodiment 1~5 culture effect analysis:

[0057] see image 3 , when Examples 1 to 5 carried out heterotrophic culture, it was found that the biomass increased with the prolongation of the culture time. After cultivating for 8 days, the biomass dry weight concentration of Examples 1 to 5 were respectively 1.12g / L and 1.71g / L , 1.96g / L, 1.77g / L and 1.76g / L, while Example 3 (that is, the concentration of glucose in medium I was 15g / L) had the highest biomass dry weight concentration, but in the early stage (cultivation time Figure 4 ), it can be seen that there is a negative correlation between the concentration of carbon source and the content of fucoxanthin, that is, the content of fucoxanthin decreases with the increas...

Embodiment 6

[0059] Cultivate Cyclotella as follows:

[0060] (1) The activated Cyclotella shake flask was cultured heterotrophically for 7 days to obtain the seed solution in the logarithmic growth phase;

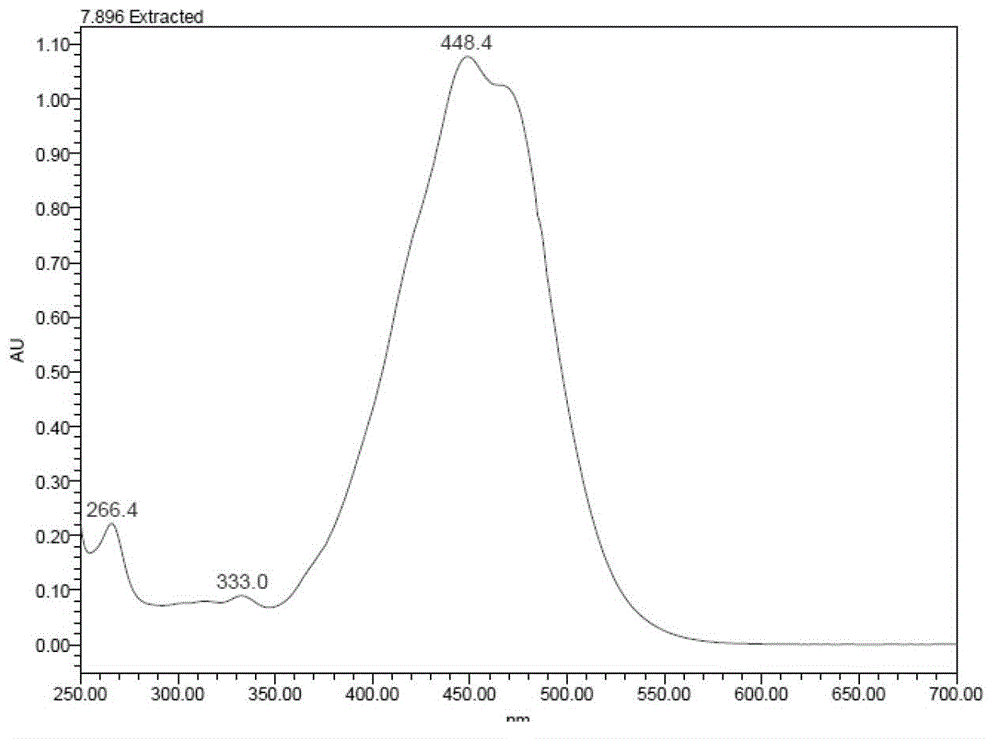

[0061] (2) The fermenter was used as the culture vessel for batch culture, and a 5L glass fermenter was selected with a working volume of 3.5L. Inject the Chlorella seed liquid into the newly prepared medium Ⅰ according to the inoculum amount of 15% (v / v), the initial biomass concentration is converted to dry weight of 0.29g / L, control the dissolved oxygen saturation > 50%, and stir The speed is 130rpm, the pH is controlled at 7.5, the culture temperature is controlled at 27±0.5°C, and the fermentation period is 9 days (216 hours). Samples were taken every 24 hours to measure the dry weight. After 3 days of culture (>72h), samples were taken every 24 hours and freeze-dried, then the pigment was extracted, and the content of fucoxanthin was quantitatively determined by liquid chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com