System and method for predicating amount of refining slag required during refining and desulfuration of LF (Ladle Furnace) on line

A technology of refining slag and sulfur content, applied in the direction of improving process efficiency, etc., can solve the problems of unfavorable molten steel desulfurization, affecting the accuracy of model prediction, and temperature prediction affecting the accurate calculation of sulfur distribution ratio, so as to reduce labor intensity and improve production automation level, the effect of ensuring reasonableness and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation of the system and method for predicting the amount of refining slag according to the present invention will be described in detail below in conjunction with the accompanying drawings.

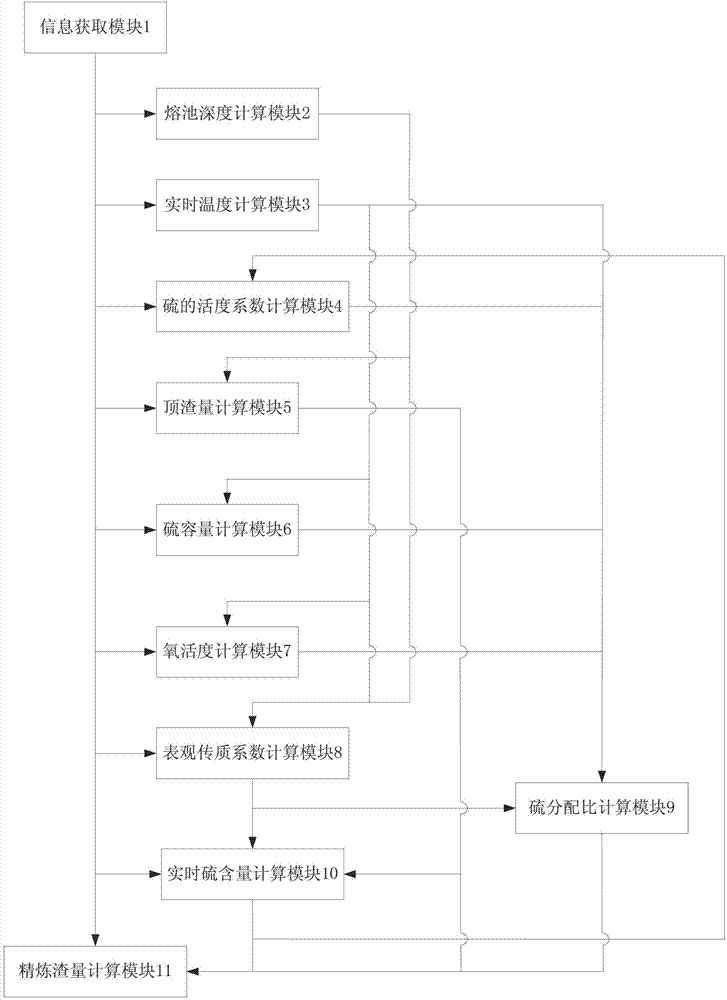

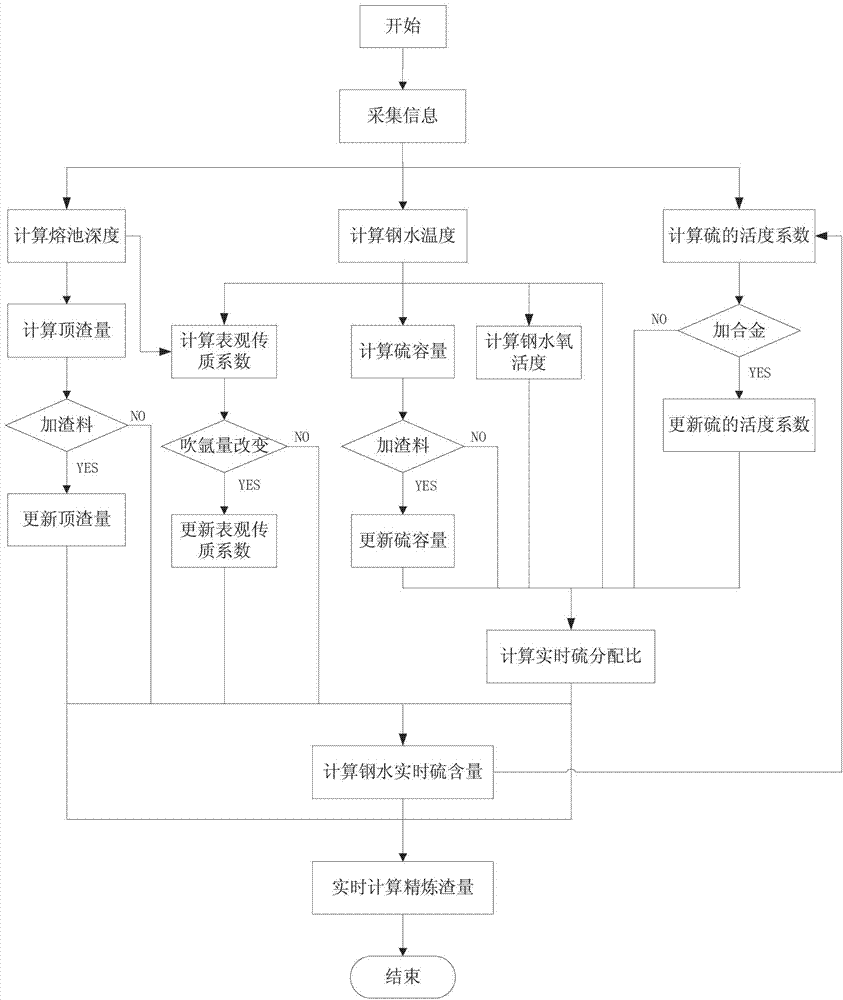

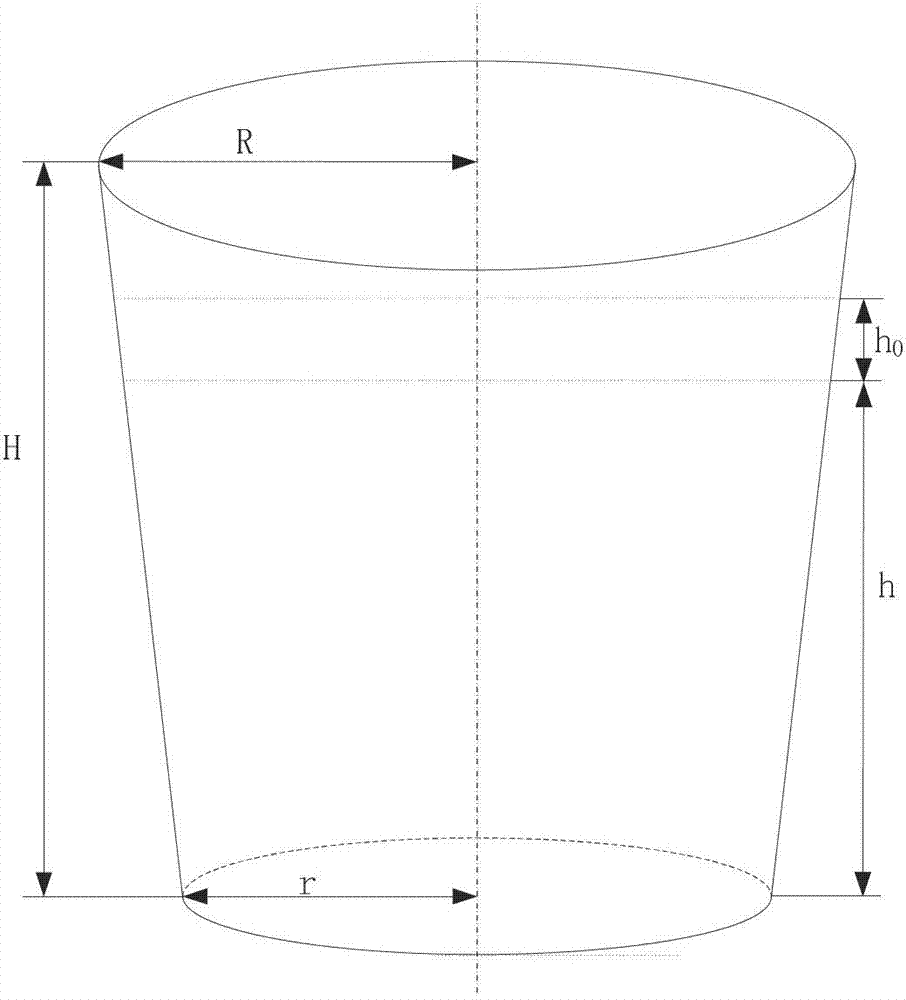

[0057] This implementation mode is applied to the system for online prediction of molten steel composition in the RH refining process at the industrial site, as shown in the attached figure 1 Shown includes: information acquisition module 1, which is used to obtain ladle size, molten steel amount, molten steel composition, target composition of corresponding steel type, initial temperature of molten steel, heating efficiency of each gear, top slag temperature, top slag composition, slag layer thickness , argon blowing amount, final slag sulfur content, slag material composition and corresponding silo number, thermal effect of alloy and slag material; molten pool depth calculation module 2, calculates molten steel molten pool depth according to molten steel amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com