Detection method for protein adulteration of milk products

A detection method and protein technology, which is applied in the detection field of dairy protein adulteration, can solve the problems of low penetration rate and high cost, and achieve the effect of high recognition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

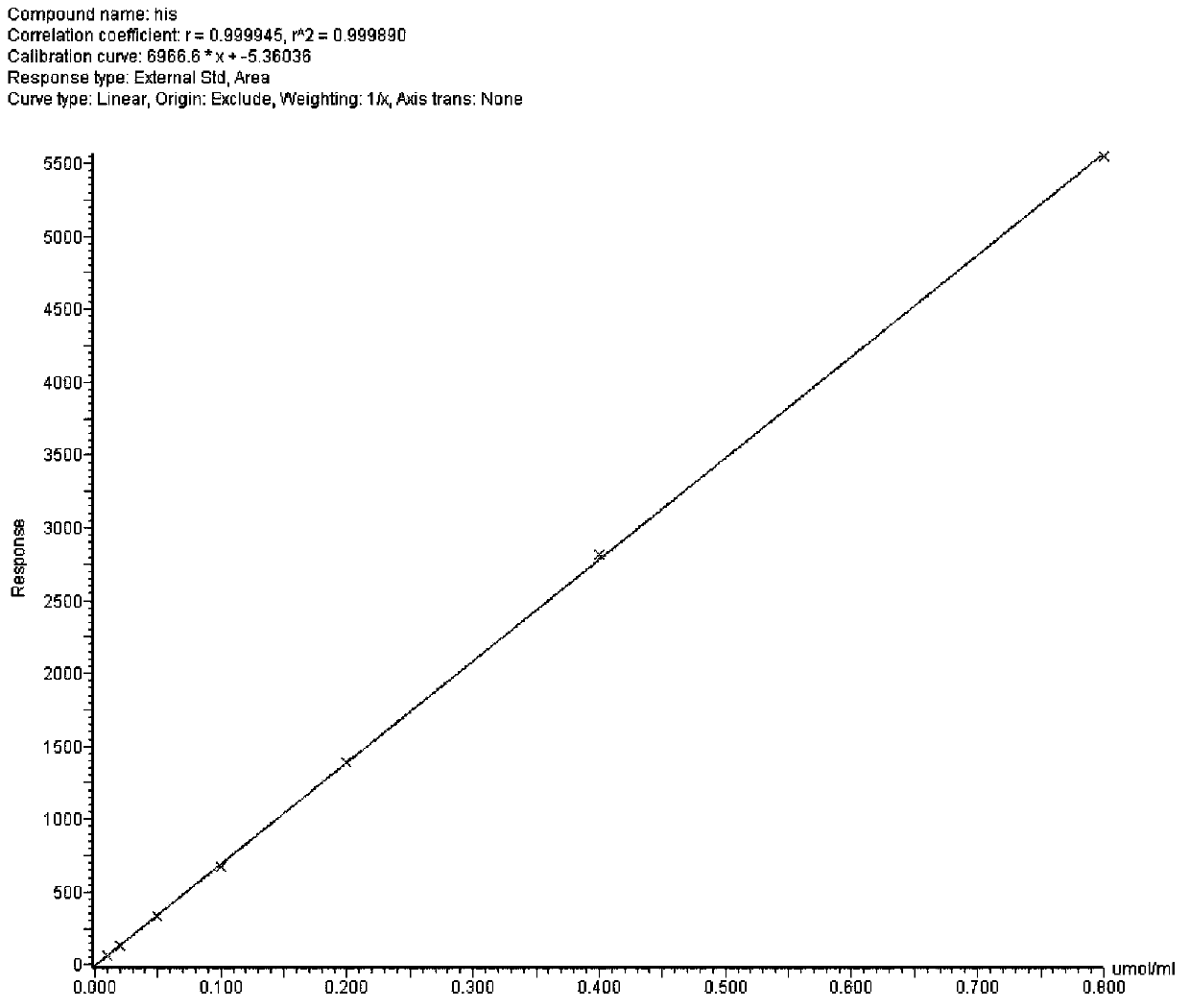

[0040] Example 1 Amino Acid Analysis

[0041] 1. Instruments and reagents

[0042] Waters ACQUITY high-pressure liquid chromatography system, including a photodiode array (PDA) detector with a flow cell, a 2 μL quantitative loop, and an Empower chromatographic workstation (Waters, USA); AccQ.TagTM Ultra Column (2.1×100mm, 1.7 μm );

[0043] Amino acid standards; reagents are chromatographically pure; Wahaha purified water (filtered before use).

[0044] 2. Source of standard samples

[0045] Raw milk samples were collected from the cattle farm of Beijing Sanyuan Dairy Co., Ltd. from November 2010 to November 2011, and a total of 500 valid samples were collected.

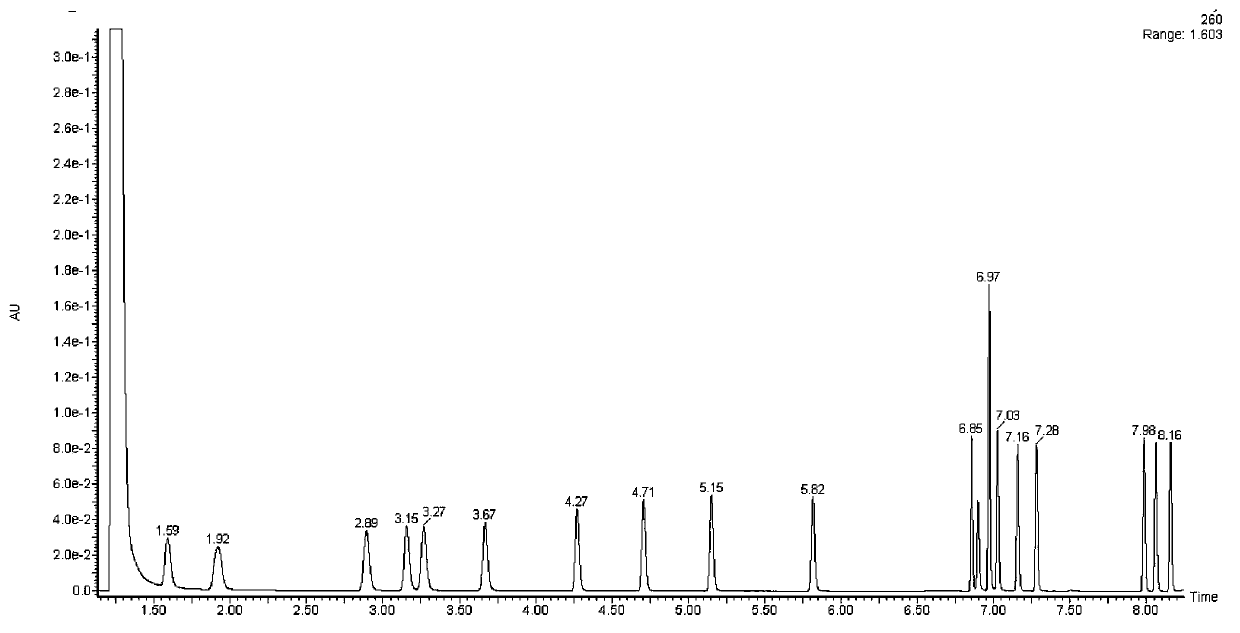

[0046] 3. Collection of raw milk amino acid chromatographic data

[0047] 3.1 Hydrolysis of milk samples

[0048] 200 μL milk sample + 1800 μL hydrochloric acid, so that the final concentration of hydrochloric acid reaches 6M. Hydrochloric acid is widely used because it has two forms, gas phase and liquid phase...

Embodiment 2

[0086] The optimization of embodiment 2 hydrolysis conditions

[0087] At present, the more common hydrolysis conditions are: 6M hydrochloric acid hydrolysis at 110°C for 20h or 24h, but it is time-consuming, which makes the detection results lag. Increase the hydrolysis temperature to 150°C, shorten the hydrolysis time to 3.5h, and compare the two hydrolysis conditions for 20 groups of samples. After statistical analysis, the results showed that the differences in the contents of 17 amino acids were not significant (p<0.05). The recovery rate of amino acid after hydrolysis of milk protein can reach 90±2%, so the hydrolysis condition is determined to be 150°C, 3.5h

Embodiment 3

[0088] Embodiment 3 detects sample A

[0089] 1. Instruments and reagents

[0090] Waters ACQUITY high-pressure liquid chromatography system, including a photodiode array (PDA) detector with a flow cell, a 2 μL quantitative loop, and an Empower chromatographic workstation (Waters, USA); AccQ.TagTM Ultra Column (2.1×100mm, 1.7 μm );

[0091] Amino acid standards; reagents are chromatographically pure; Wahaha purified water (filtered before use).

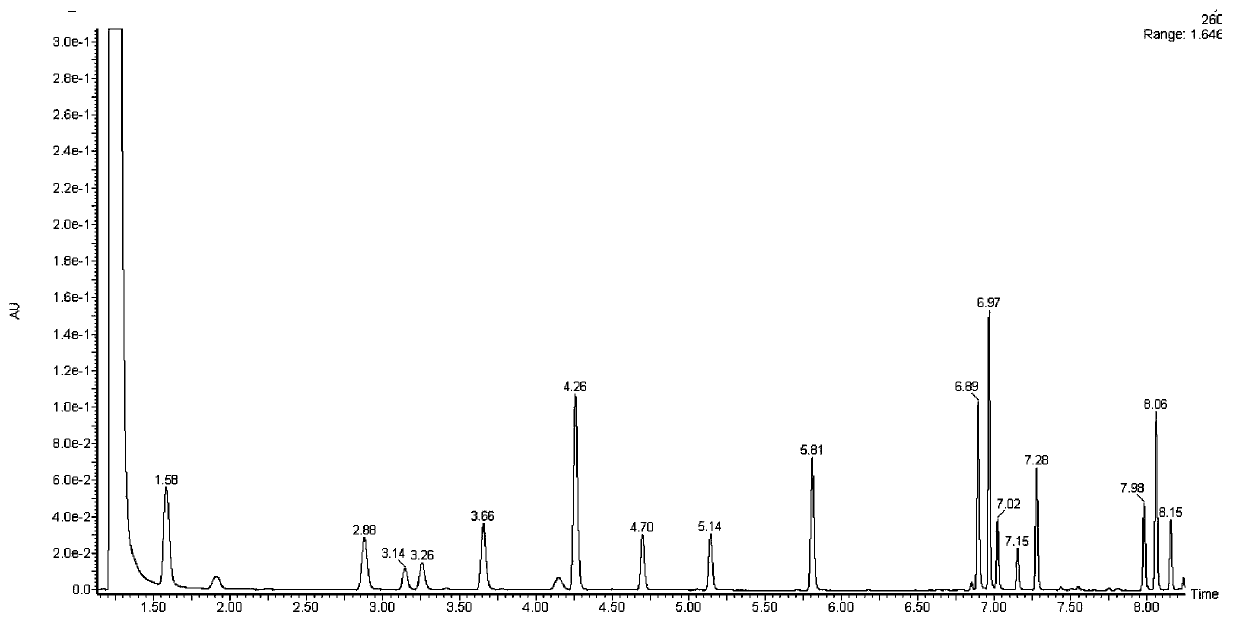

[0092] 2. Collection of amino acid chromatographic data of milk sample A to be tested

[0093] 2.1 Hydrolysis of milk samples

[0094] 200 μL milk sample + 1800 μL hydrochloric acid, so that the final concentration of hydrochloric acid reaches 6M. The hydrolysis temperature is 150°C, and the hydrolysis time is 3.5 hours.

[0095] 2.2 Neutralization of hydrolyzed samples

[0096] Mix equal volumes of 6M NaOH with the hydrolyzed sample to neutralize the sample.

[0097] 2.3 Determination of high pressure liquid chromatography

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com