Aanalysis method of residual quantities of eighteen photoinitiators in ultra violet (UV) printing ink

A photoinitiator and printing ink technology, applied in the field of analysis of 18 kinds of photoinitiator residues in UV printing ink, can solve the problems of time-consuming, cumbersome, high cost, etc., and achieve the effect of improving the detection throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

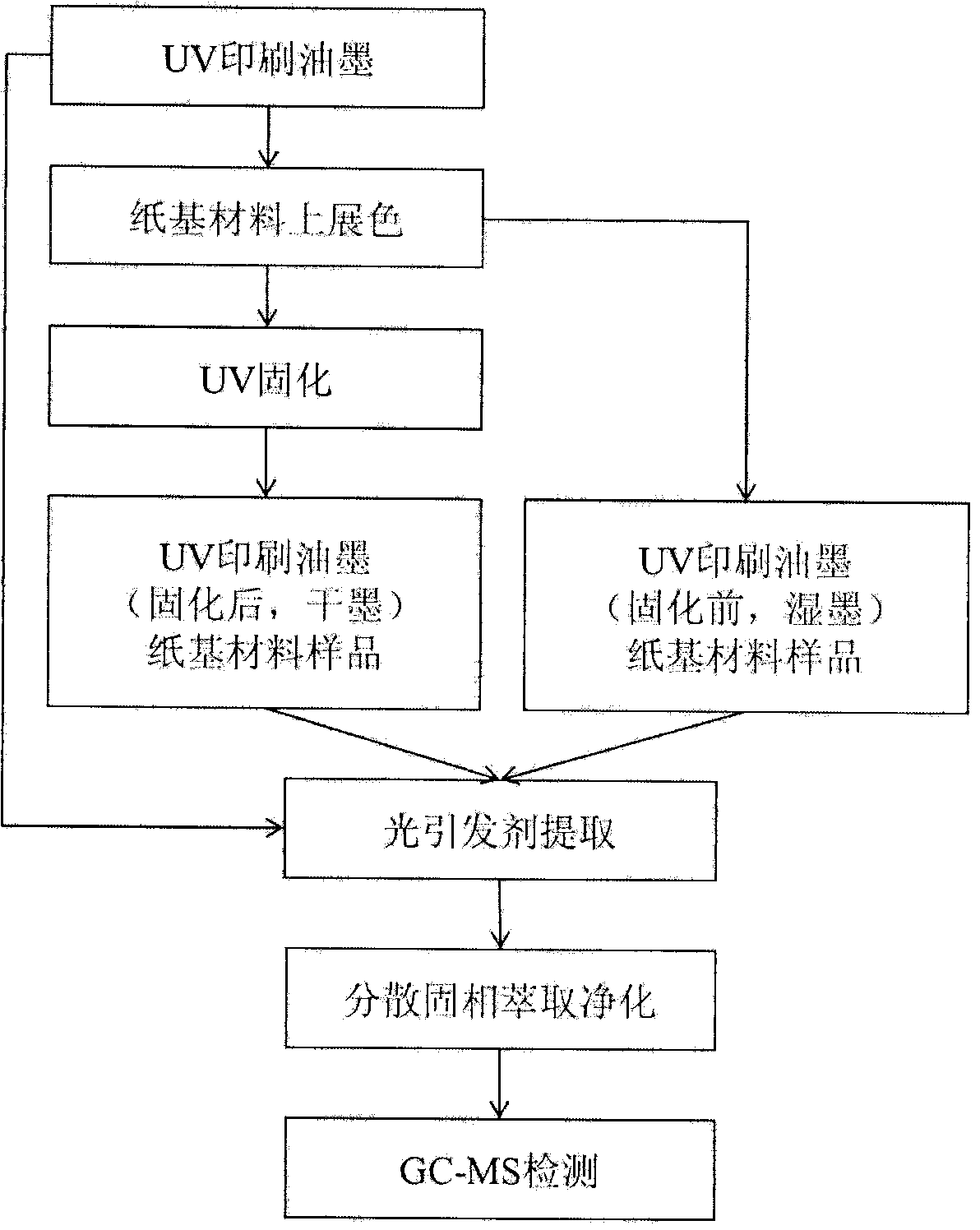

Method used

Image

Examples

example 1

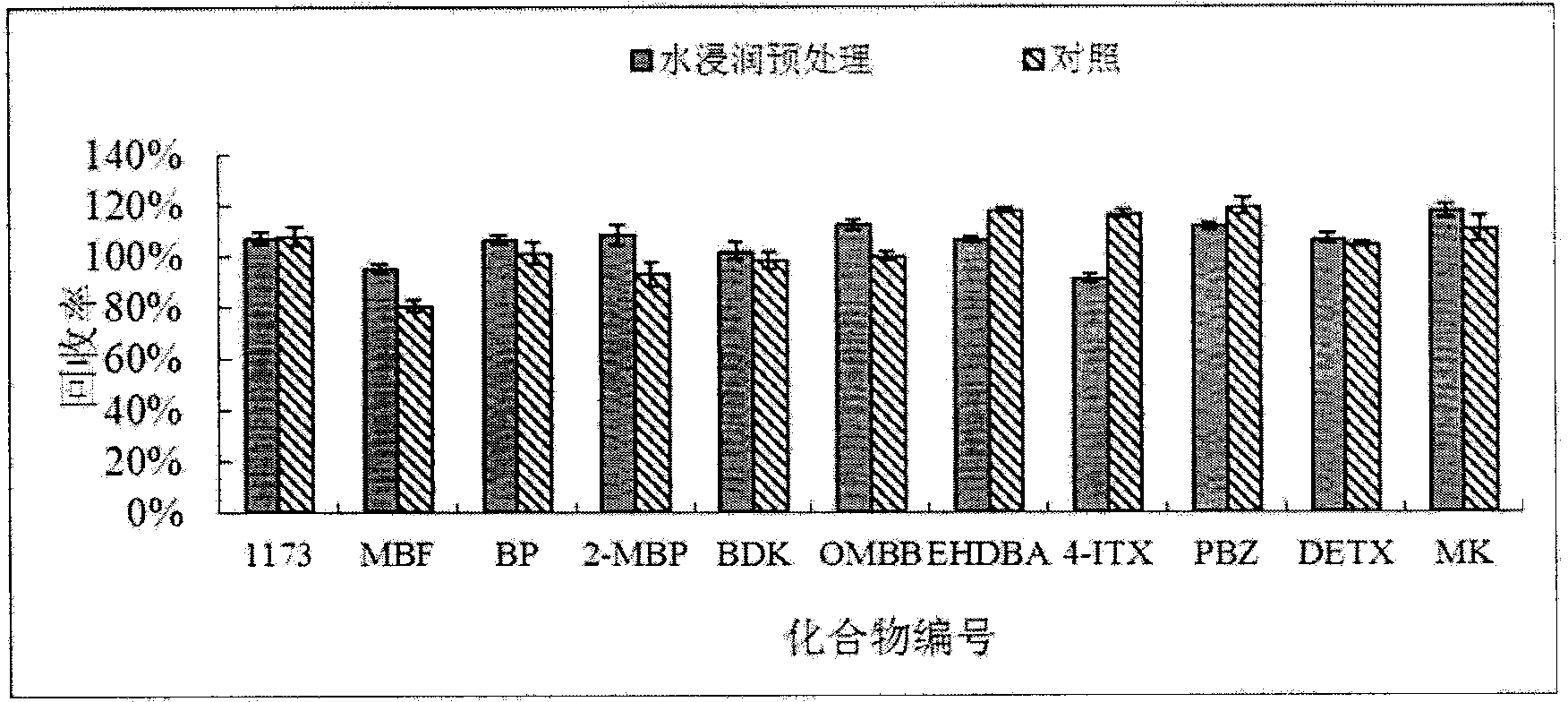

[0080] The experimental results show that 30 min water immersion pretreatment of the sample can promote the peeling between the bonded layers of the composite paper material or cardboard material, which can better ensure the extraction of the residue inside the sample, thus greatly improving the gloss in the sample. Initiator extraction efficiency. In addition, the experiment also found that when the acetonitrile / water extract of the sample and n-hexane-ethyl acetate solution (3:7, V / V) were subjected to liquid-liquid partitioning, most of the extracted ink dyes were dispersed in the water phase, The co-extracted substances in the organic phase are reduced, so that the sample extraction solution has a certain purification effect.

[0081] Finally, this experiment determined that the sample was extracted by water immersion pretreatment.

[0082]

[0083] Example 2:

example 2

[0085] At present, the sample pretreatment methods for photoinitiator determination are mainly liquid-liquid extraction (LLE) and solid-phase extraction (SPE) techniques that are cumbersome, time-consuming, and require a large amount of solvent. After experiments, it was found that conventional solid-phase extraction still has a large resistance, which leads to poor impurity removal effect, while the dilution and impurity removal method will greatly reduce the sensitivity of the detection method.

[0086] In recent years, sample pretreatment methods are developing towards simplification, saving and miniaturization. QuEChERS (Quick, Easy, Cheap, Effective, Rugged and Safe) was first proposed and reported by Anastassiades and Lehotay in 2003. The core of its technology is to add water remover and purifier to the sample extract to remove excess water and impurities , the clarified solution was analyzed directly after centrifugation. Compared with the traditional solid-phase extr...

example 3

[0092]

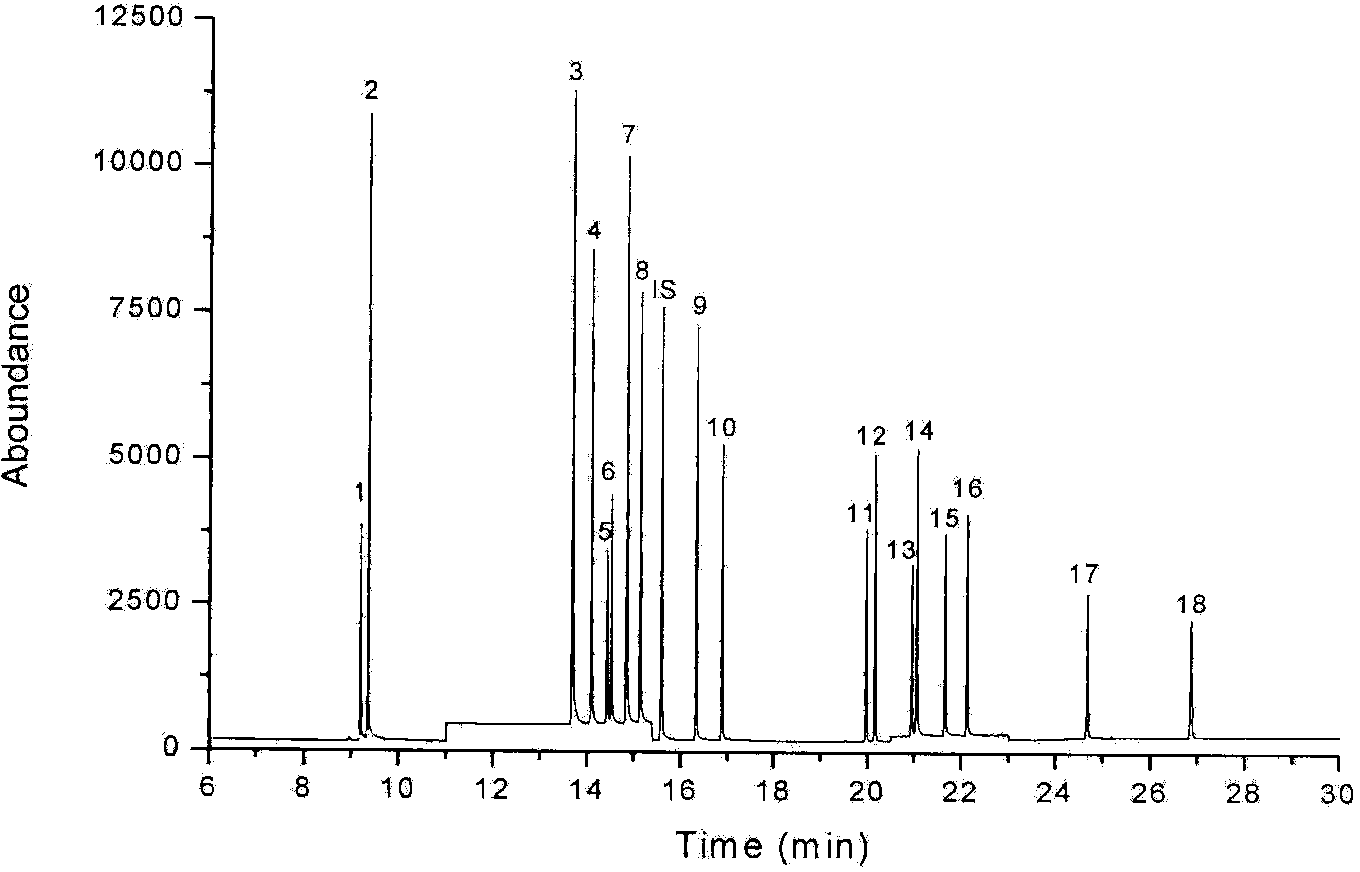

[0093] From the results of the method evaluation, it can be seen that the compounds are well separated, the sensitivity of the method is high, and the linear relationship is good within the concentration range of 0.2 mg / L~10 mg / L (R 2 >0.995), meeting the evaluation requirements of detection methodology.

[0094]

[0095] Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com