Adhesive for negative materials for lithium-ion battery and method for preparing electrode containing adhesive

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor low-temperature discharge performance, and achieve the effects of excellent adhesive strength, good charge-discharge rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

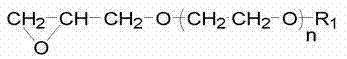

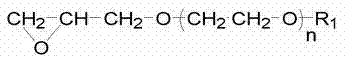

[0026] Example 1, a binder for lithium-ion battery anode materials, which is a polyether polymer, and the polyether polymer includes: 50 mol% of repeating monomers derived from structural formula (I) unit,

[0027]

[0028] (I)

[0029] Among them, R 1 is a methyl group, and the value of n is 2;

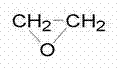

[0030] 45 mol% of repeating units derived from monomers represented by structural formula (II);

[0031]

[0032] (Ⅱ)

[0033] and 5 mol% of repeating units derived from monomers represented by structural formula (III):

[0034]

[0035] (Ⅲ)

[0036] Wherein, X is a silicon group.

Embodiment 2

[0037] Example 2, a binder for negative electrode materials of lithium-ion batteries, which is a polyether polymer, and the polyether polymer includes: 1 mol% of a monomer derived from the structural formula (I) the repeating unit of

[0038]

[0039] (I)

[0040] Among them, R 1 is ethyl, and the value of n is 4;

[0041] 89 mol% of repeating units derived from monomers represented by structural formula (II);

[0042]

[0043] (Ⅱ)

[0044] and 10 mol% of repeating units derived from monomers represented by structural formula (IV):

[0045]

[0046] (Ⅳ)

[0047] Wherein, X is an epoxy group, and the value of m is 1.

Embodiment 3

[0048] Example 3, a binder for negative electrode materials of lithium-ion batteries, which is a polyether polymer, and the polyether polymer includes: 30mol% of monomers derived from structural formula (I) the repeating unit of

[0049]

[0050] (I)

[0051] Among them, R 1 is propyl, and the value of n is 6;

[0052] 69 mol% of repeating units derived from monomers represented by structural formula (II);

[0053]

[0054] (Ⅱ)

[0055] and 1 mol% of repeating units derived from monomers represented by structural formula (IV):

[0056]

[0057] (Ⅳ)

[0058] Wherein, X is an ethylenically unsaturated group, and the value of m is 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com