High-temperature brazed connection method for C/C composite material and nickel-based high-temperature alloy

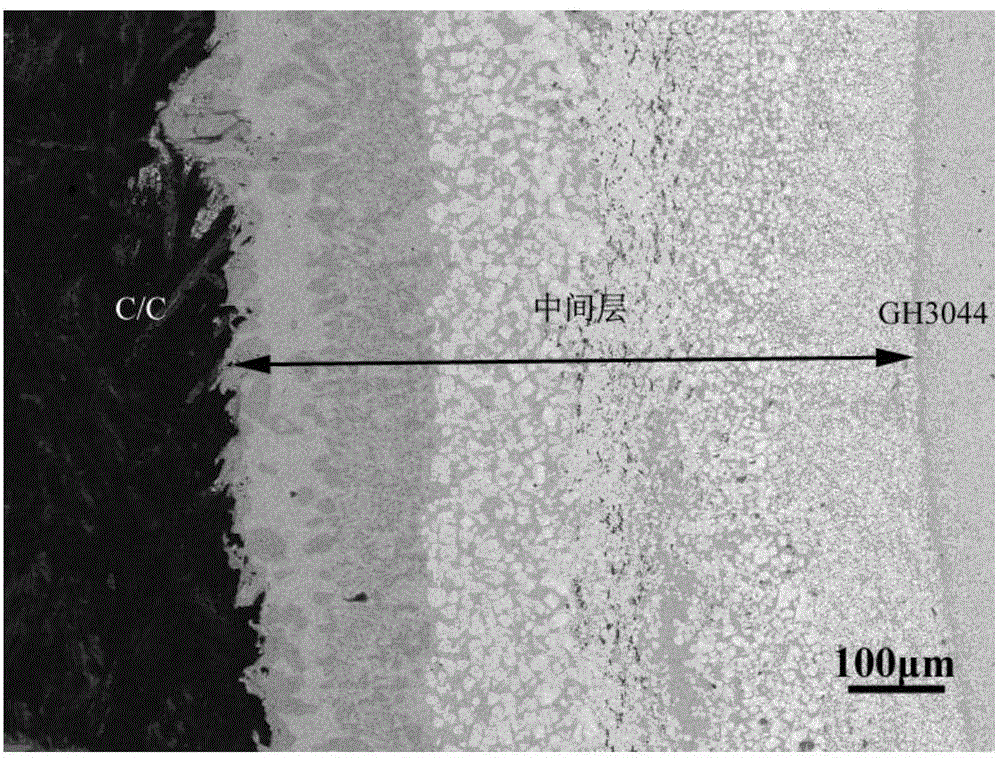

A technology for nickel-based superalloys and composite materials, which is applied in the field of brazing connection between C/C composite materials and nickel-based superalloys, and can solve the problem of difficult wetting of nickel-based alloys, large differences in physical and chemical properties, and poor chemical compatibility. problem, to achieve the effect of good connection and alleviation of thermal expansion coefficient mismatch problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A 15mm×10mm×4mm C / C composite material and a nickel-based superalloy of equal size were brazed at 1160°C.

[0024] Step 1: Grind and polish the C / C composite material with No. 320 and No. 600 water sandpaper, then ultrasonically clean it in anhydrous ethanol for 30 minutes, and finally dry it in an oven at 80°C for 60 minutes before use.

[0025] Step 2, preparing a SiC coating on the surface of the C / C composite material by an embedding method.

[0026] Step 3, brazing connection of the C / C composite material and the nickel-based alloy. Specific process:

[0027] 1) Grind and polish the surface of the nickel-based superalloy to be connected with sandpaper, then clean the surface of the nickel-based superalloy to be connected with absolute ethanol, and dry it in an oven at 80°C for 30 minutes;

[0028] 2) Weigh an appropriate amount of BNi71CrSi solder and mix it with alcohol, and stir until uniform;

[0029] 3) Coat the BNi71CrSi slurry evenly on the surface-modifie...

Embodiment 2

[0037] A 25mm×10mm×6mm C / C composite material and a nickel-based superalloy of equal size were brazed at 1170°C.

[0038] Step 1: Grind and polish the C / C composite material with No. 320 and No. 600 water sandpaper, then ultrasonically clean it in absolute ethanol for 60 minutes, and finally dry it in an oven at 100°C for 50 minutes before use.

[0039] Step 2, preparing a SiC coating on the surface of the C / C composite material by an embedding method.

[0040] Step 3, brazing connection of the C / C composite material and the nickel-based alloy. Specific process:

[0041] 1) Grind and polish the surface of the nickel-based superalloy to be connected with sandpaper, then clean the surface of the nickel-based superalloy to be connected with absolute ethanol, and dry it in an oven at 100°C for 30 minutes;

[0042] 2) Weigh an appropriate amount of BNi71CrSi solder and mix it with alcohol, and stir until uniform;

[0043] 3) Coat the BNi71CrSi slurry evenly on the surface-modified...

Embodiment 3

[0051] A 10mm×10mm×4mm C / C composite material and a nickel-based superalloy of equal size were brazed at 1180°C.

[0052] Step 1: Grind and polish the C / C composite material with No. 320 and No. 600 water sandpaper, then ultrasonically clean it in absolute ethanol for 30 minutes, and finally dry it in an oven at 100°C for 40 minutes before use.

[0053] Step 2, preparing a SiC coating on the surface of the C / C composite material by an embedding method.

[0054] Step 3, brazing connection of the C / C composite material and the nickel-based alloy. Specific process:

[0055] 1) Grind and polish the surface of the nickel-based superalloy to be connected with sandpaper, then clean the surface of the nickel-based superalloy to be connected with absolute ethanol, and dry it in an oven at 120°C for 30 minutes;

[0056] 2) Weigh an appropriate amount of BNi71CrSi solder and mix it with alcohol, and stir until uniform;

[0057] 3) Coat the BNi71CrSi slurry evenly on the surface-modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com