Degradable quick plugging agent

A plugging agent and fast technology, applied in the field of materials, can solve the problems of high working pressure, easy shrinkage, troublesome handling, etc., to achieve the effect of improving the success rate, good degradability, and easy plugging removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

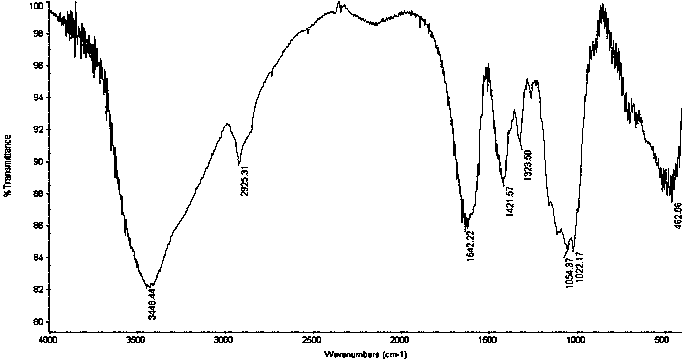

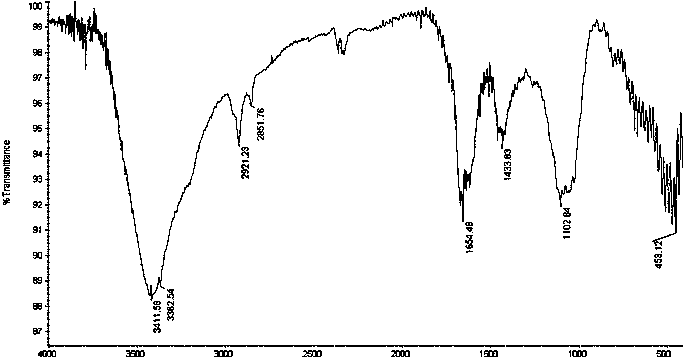

Image

Examples

example 1

[0054] (2) Dissolve carboxymethyl cellulose sodium salt in 60 mL of distilled water first, then add acrylamide, stir to dissolve it, put it in a 40°C water bath and heat for about half an hour to mix the two evenly. Add the initiator ammonium persulfate and stir evenly, control the pH to about 7, and react for 8-9 hours. The cross-linking reaction can be stopped when the glass rod is dipped to draw a wire length of about 10 cm.

[0055] (3) Cool the cross-linked product solution as the base liquid A, which can be put into practical use for plugging. At the same time, the base liquid A can also be heated and dried to become powder, which is convenient for storage and transportation. It can be prepared with distilled water on site when used. It is prepared and used immediately, and the viscosity of the base liquid can be adjusted according to the amount of water. This example directly uses the base liquid A solution just prepared

[0056] 2. Preparation of inorganic crosslinki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com