Method for improving Trametes versicolor laccase output

A technology of Trametes versicolor and laccase, applied in the field of bioengineering, can solve the problems of high-yielding strains, such as difficulty, limited improvement, no advantage in output, etc., to reduce the production cost of laccase, increase the area, and meet the effects of large-scale application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Activation and pre-cultivation of Trametes versicolor

[0040] Trametes versicolor (Trametes versicolor) was purchased from China Industrial Microorganism Culture Collection Management Center, number CICC14001.

[0041] (1) activation

[0042] The medium for slant activation was prepared by the usual potato medium preparation method, including 200g / L potato, 20g / L glucose, and 15g / L agar powder; Trametes versicolor (CICC14001) was inoculated on the medium, and cultured at 30°C for 7 sky.

[0043] (2) Pre-cultivation

[0044] Prepare the medium for pre-cultivation by using the common potato medium preparation method, including 200g / L potato and 20g / L glucose; inoculate the activated mycelium in the medium, and cultivate it at 25°C and 150r / min 7 days; After homogenizing the culture, inoculate 10% (v / v) inoculum into fresh medium and culture for 5 days to obtain pre-cultured mycelia for laccase fermentation.

[0045] A specific example of Trametes versicolo...

Embodiment 2

[0047] Embodiment 2: Trametes versicolor laccase fermentation

[0048] (1) Under the conditions of temperature 26°C, pH 6.0, stirring rate 400rpm and air flow 0.5vvm, the pre-cultured Trametes versicolor mycelium was inoculated into the laccase fermentation medium with an initial biomass of 2g / L , carry out fermentation culture under this condition;

[0049] (2) Dissolve farnesol in ethanol at a concentration of 200 mM, filter and sterilize with a 0.22 μm filter membrane to prepare a farnesol solution;

[0050] (3) At the 0th hour of the entire culture process, add the farnesol solution in step (2) until the concentration in the fermentation broth reaches 100 μM;

[0051] (4) After 24 hours of cultivation, adjust and maintain the pH at 8.0, adjust the rotation speed to 180rpm, adjust the ventilation to 0.15vvm, and continue to cultivate under these conditions;

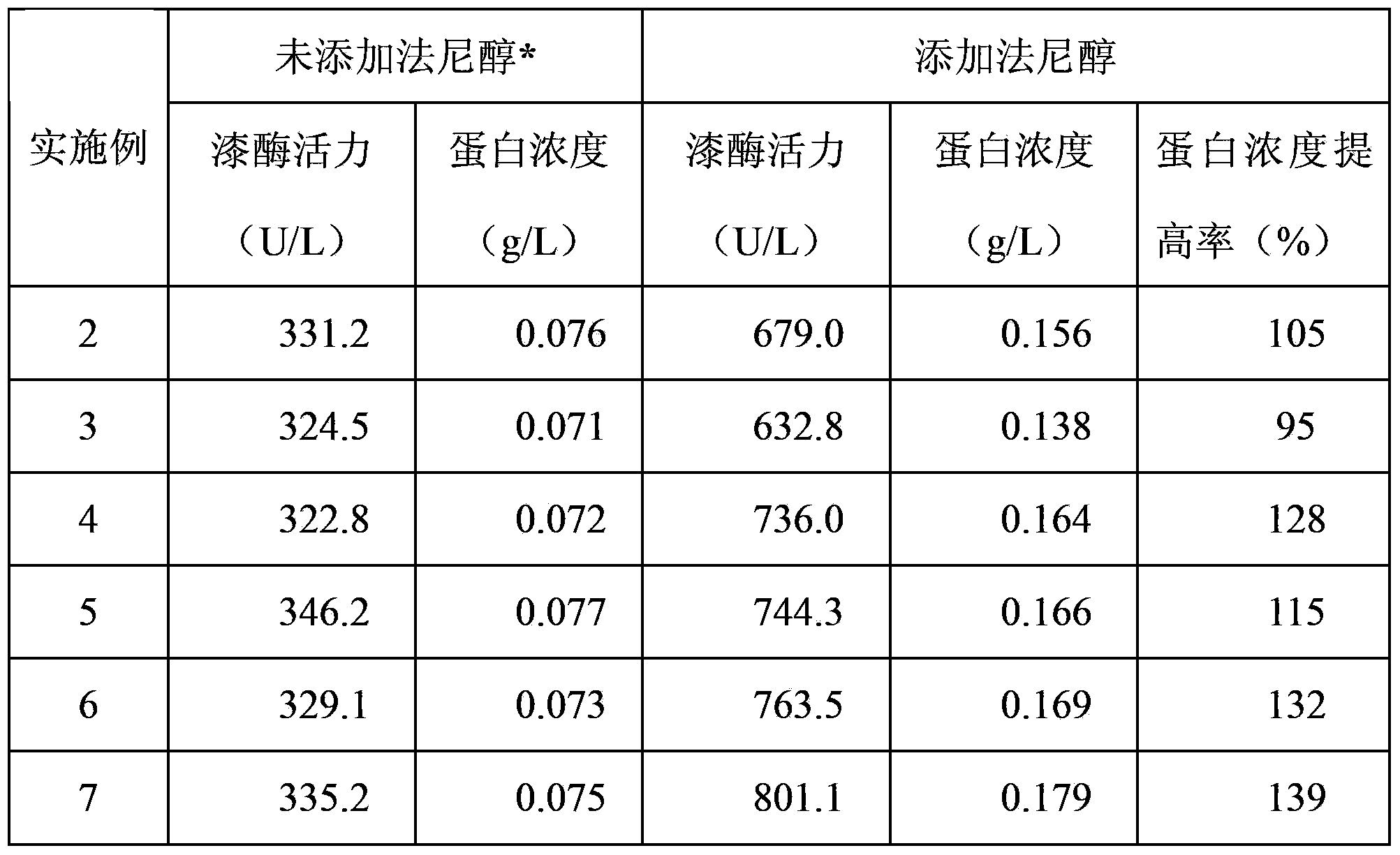

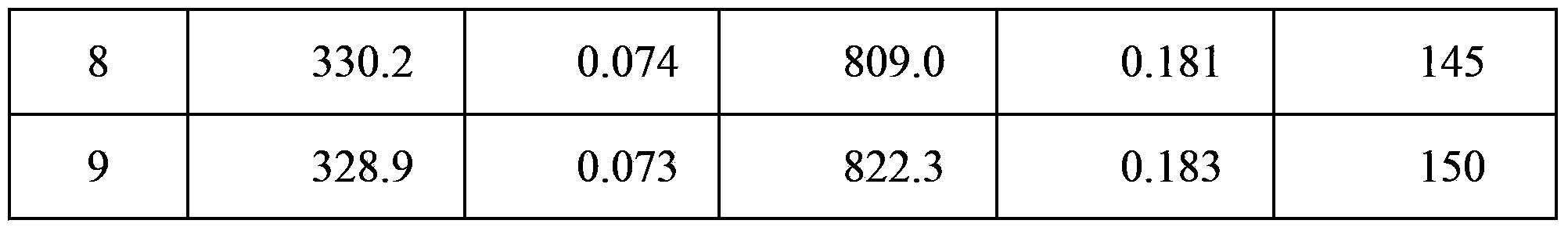

[0052] (5) After culturing for 120 hours, collect the fermentation broth, remove the mycelia and measure the lacca...

Embodiment 3

[0055] Embodiment 3: Trametes versicolor laccase fermentation

[0056] (1) Under the conditions of temperature 26°C, pH 4.1, stirring rate 200rpm and ventilation volume 0.2vvm, the pre-cultured Trametes versicolor mycelium was inoculated into the laccase fermentation medium with an initial biomass of 0.5g / L In, carry out fermentation culture under this condition;

[0057] (2) Dissolve farnesol in isopropanol at a concentration of 2 mM, filter and sterilize with a 0.22 μm filter membrane to prepare a farnesol solution;

[0058] (3) At the 36th hour of the entire culture process, add the farnesol solution in step (2) until the concentration in the fermentation broth reaches 10 μM;

[0059] (4) After culturing for 48 hours, adjust and maintain the pH at 6.1, adjust the rotation speed to 80rpm, adjust the ventilation to 0.05vvm, and continue culturing under these conditions;

[0060] (5) After culturing for 168 hours, collect the fermentation broth, remove the mycelium and measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com