Gas type detecting method and system

A gas type and detection method technology, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as narrow application range, many limiting factors, toxic and harmful electrochemically active gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

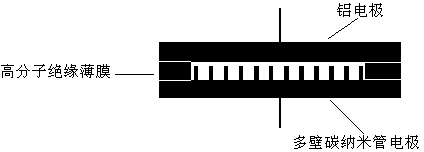

[0030] (1) Fabrication of multi-walled carbon nanotube gas sensors

[0031] a. To prepare an anodized aluminum template, the high-purity aluminum plate is ultrasonically cleaned in a mixed solution of acetone and ethanol, then polished for 10 minutes in a mixed solution of ethanol and perchloric acid with a volume ratio of 4.5:1; take it out and wash it with deionized water Then put it into 0.3mol / l oxalic acid solution, use DC voltage 40V to anodize for 1h, place it in a mixed solution of phosphoric acid and chromic acid at 50°C, remove the anodic oxide film, and then oxidize it a second time under the same oxidation conditions for 20min After taking it out, expand the hole in 5% phosphoric acid solution at 50°C for 15 minutes.

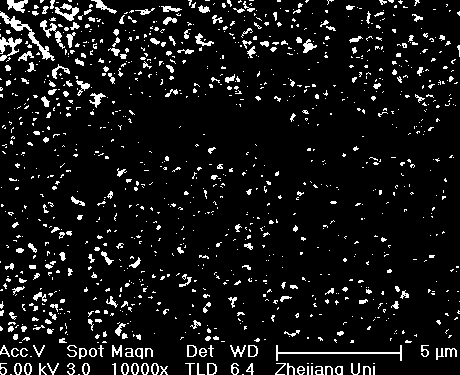

[0032] The prepared anodized aluminum template such as figure 1 As shown, the pore size, pore spacing and depth of the anodized aluminum template are 60nm, 100nm and 2μm, respectively.

[0033] b. Directional synthesis of carbon nanotubes, heat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com