Horizontal high-voltage device and manufacturing method of horizontal high-voltage device

A lateral high voltage, manufacturing method technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as rising on-resistance, reduce resistivity, reduce on-resistance, and reduce chip area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

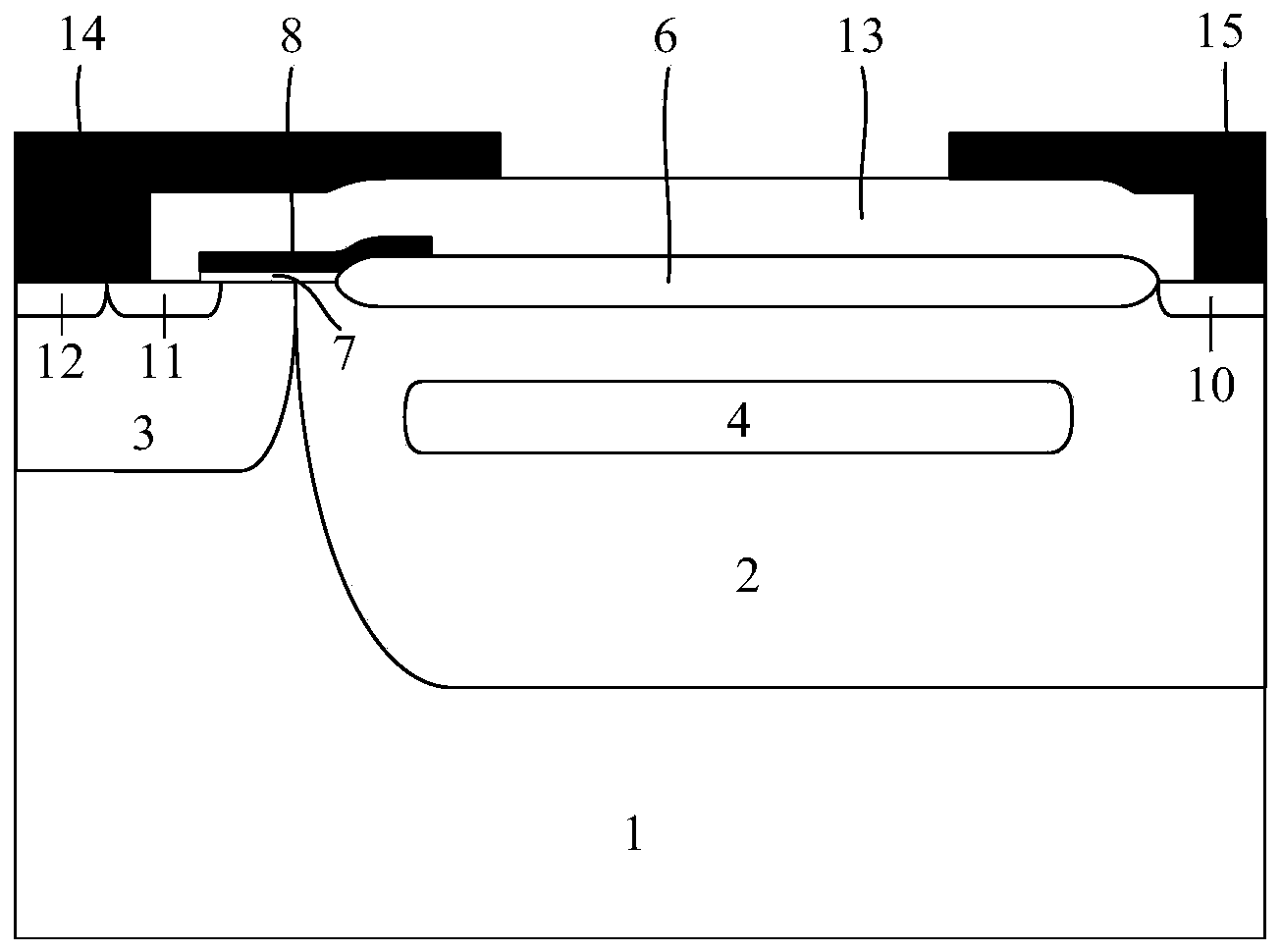

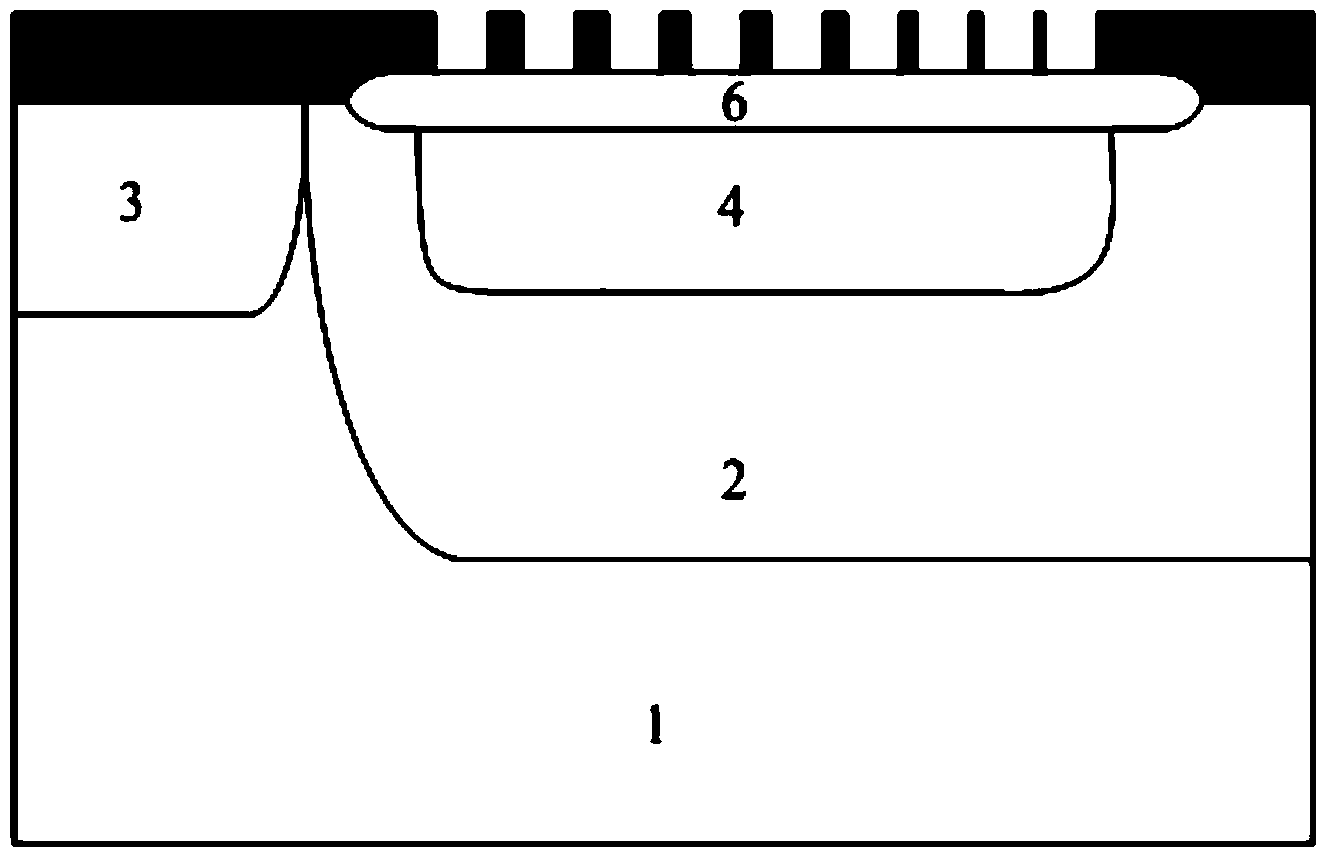

[0057] The adopted process of this example is that the second conductivity type semiconductor heavily doped layer 5 has a plurality of smaller ion implantation windows, the size of the small windows is the same, and the spacing of the windows is different, along with the second conductivity type semiconductor drain region 10 (or the first conductivity type semiconductor anode region) approaching, the injection window gradually decreases, such as image 3 shown. Figure 4 It is a cross-sectional view of the device structure after implantation of semiconductor impurities of the second conductivity type. In the figure, the semiconductor impurities 9 of the second conductivity type are diffused by annealing to form a heavily doped layer 5 of the semiconductor of the second conductivity type with a linear doping distribution, such as Figure 5 shown. At the same time, the field oxide layer 6 is formed before the push-well process of the first conductivity type semiconductor field ...

Embodiment 2

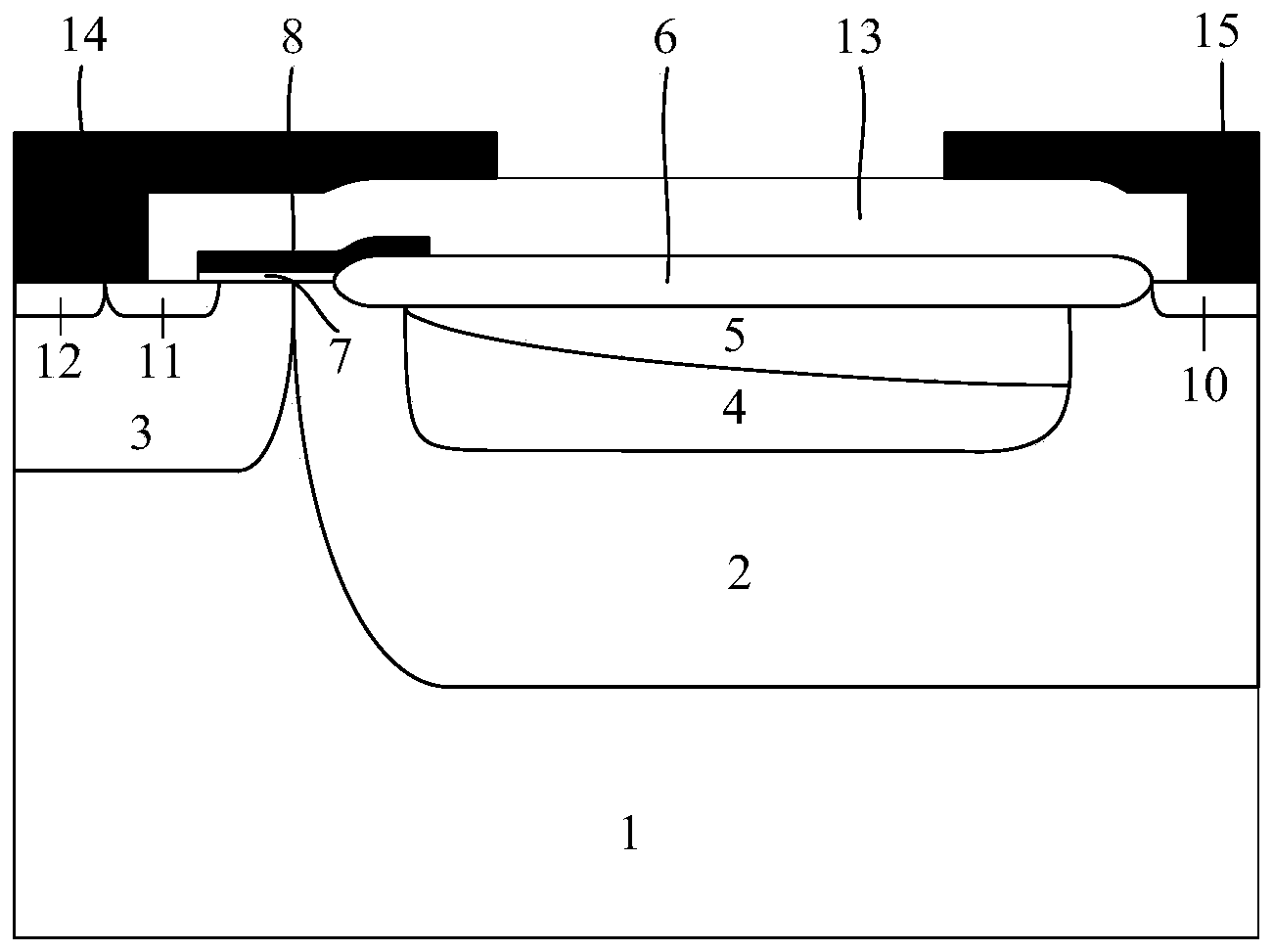

[0059] The process used in this example is to first form the first conductive type semiconductor field drop layer 4 and the second conductive type semiconductor heavily doped layer 5, and then form the field oxide layer 6, the first conductive type semiconductor field drop layer 4, The second conductivity type semiconductor heavily doped layer 5 and the field oxide layer 6 are annealed together. At the same time, the second conductivity type semiconductor heavily doped layer 5 has a plurality of smaller ion implantation windows, the size of the implantation windows is the same, the spacing is different, and the window spacing gradually decreases as it approaches the second conductivity type semiconductor drain region 10, Such as Image 6 shown. Figure 7 It is a cross-sectional view of the device structure after implantation of semiconductor impurities of the second conductivity type. In the figure, the semiconductor impurities 9 of the second conductivity type are diffused b...

Embodiment 3

[0061] The adopted process of this example is that the second conductivity type semiconductor heavily doped layer 5 has a plurality of smaller ion implantation windows, the spacing of the small windows is the same, and the size of the windows is different, as the second conductivity type semiconductor drain region 10 approaches gradually decrease, as Figure 9 shown. Figure 10 It is a cross-sectional view of the device structure after implantation of semiconductor impurities of the second conductivity type. In the figure, the semiconductor impurities 9 of the second conductivity type are diffused by annealing to form a heavily doped layer 5 of the semiconductor of the second conductivity type with a linear doping distribution, such as Figure 11 shown. At the same time, the field oxide layer 6 is formed before the push-well process of the first conductivity type semiconductor field drop layer 4 , the field oxide layer 6 is formed first, and the annealing process of the field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com