Low-temperature type carbonic ester lithium battery electrolyte

An electrolyte and carbonate technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of affecting the efficiency of the battery, the inability to discharge the battery, and affecting the charging and discharging performance of the battery, so as to increase the service life and improve the stability. performance, and the effect of reducing low-temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

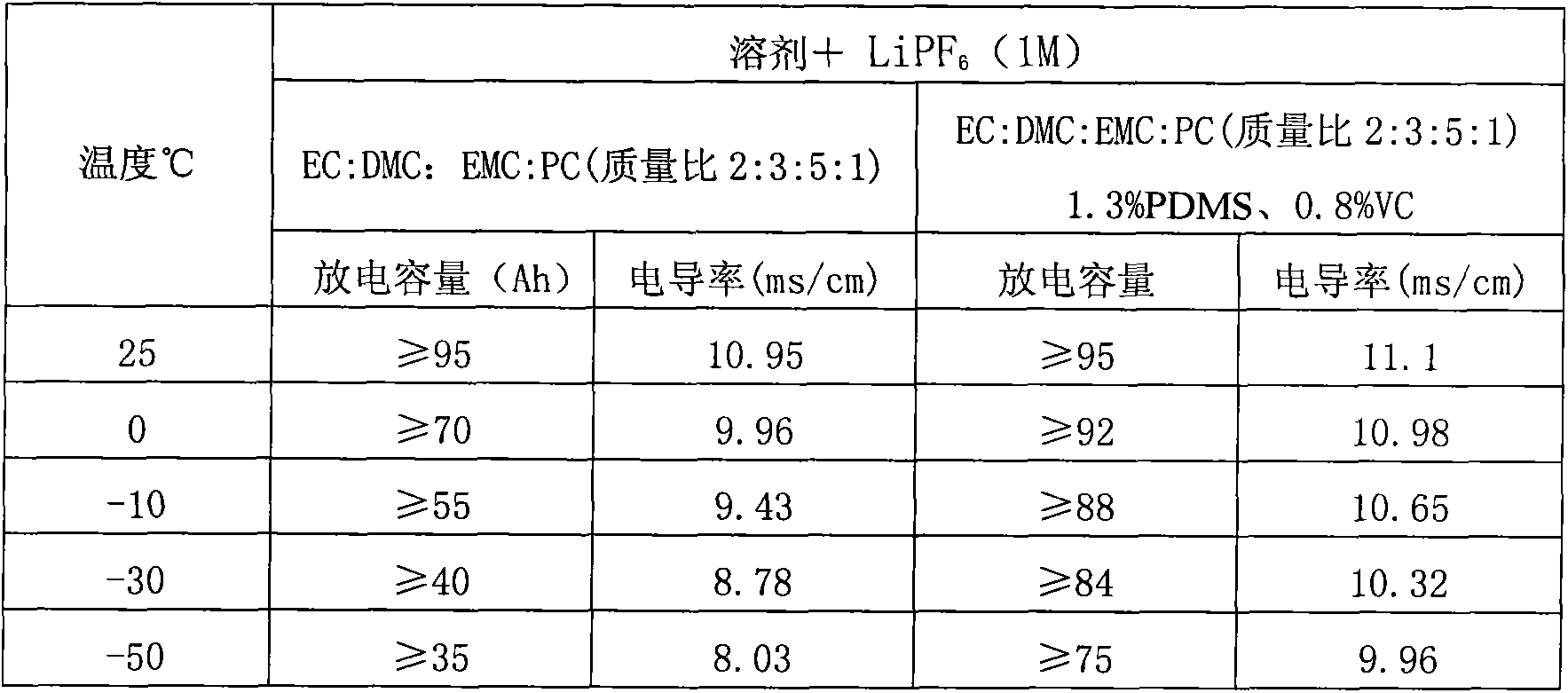

[0018] 1.3% Polydimethylsiloxane (PDMS) and 0.8% Vinylene Carbonate in Ethylene Carbonate (EC), Dimethyl Carbonate (DMC), Ethyl Methyl Carbonate (EMC) and Propylene Carbonate (PC) After the addition of ester (VC), the synergistic effect is the largest, and the discharge capacity and conductivity change greatly. It can effectively improve the low-temperature performance of lithium battery electrolyte at -50°C, and can maintain high conductivity and discharge capacity. Table 1 shows the changes in the discharge capacity and conductivity of the two electrolytes.

[0019] Table 11mol / L LiPF 6 Discharge capacity and conductivity of electrolytes composed of different solvents at different temperatures

[0020]

Embodiment 2

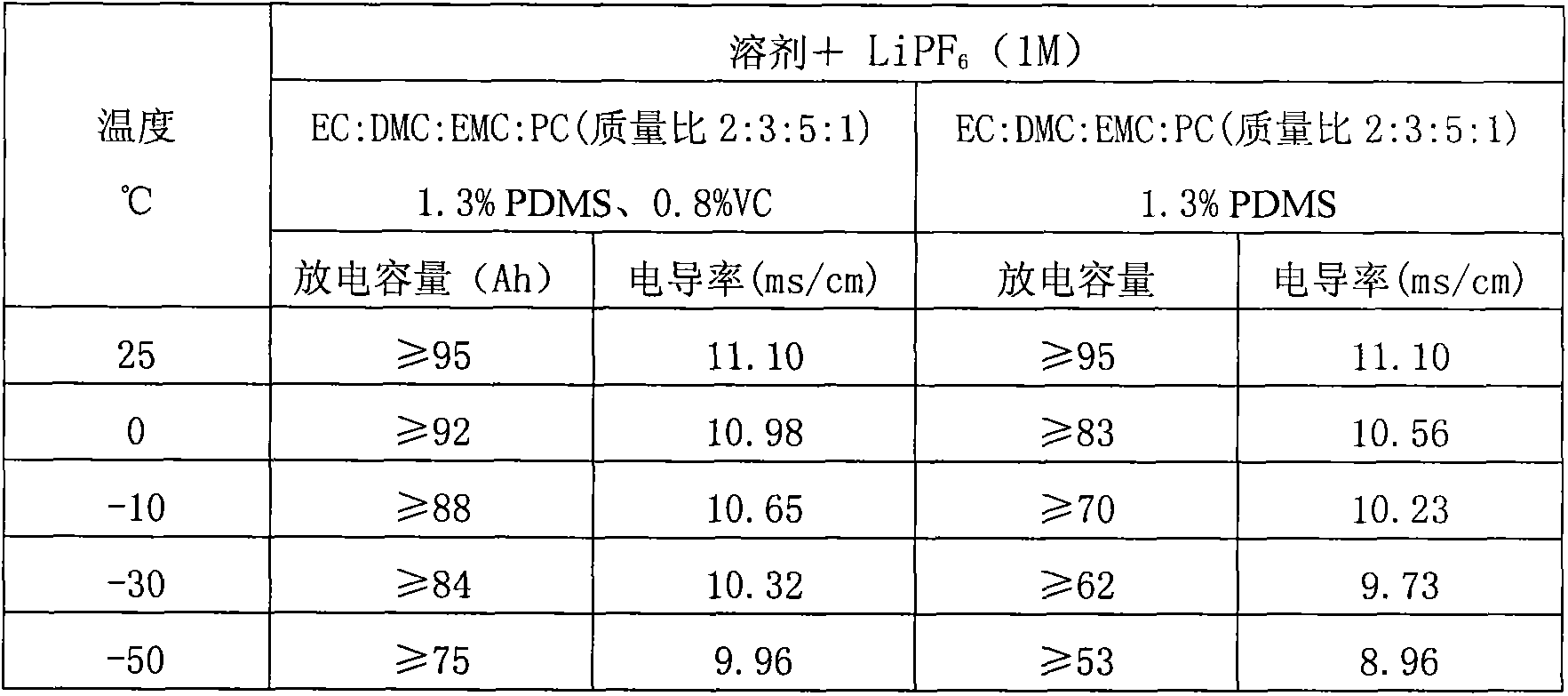

[0022] The low temperature performance was also improved after adding 1.3% polydimethylsiloxane (PDMS) additive to ethylene carbonate (EC), dimethyl carbonate (DMC), ethyl methyl carbonate (EMC) and propylene carbonate (PC). Partial improvement has been obtained, and the discharge capacity and electrical conductivity are improved compared with no additives, but the effect is not as good as the synergistic effect of the two additives. Table 2 shows the changes in the discharge capacity and conductivity of the two electrolytes.

[0023] Table 21mol / L LiPF 6 Discharge capacity and conductivity of electrolytes with the same solvent composition at different additive amounts and different temperatures

[0024]

Embodiment 3

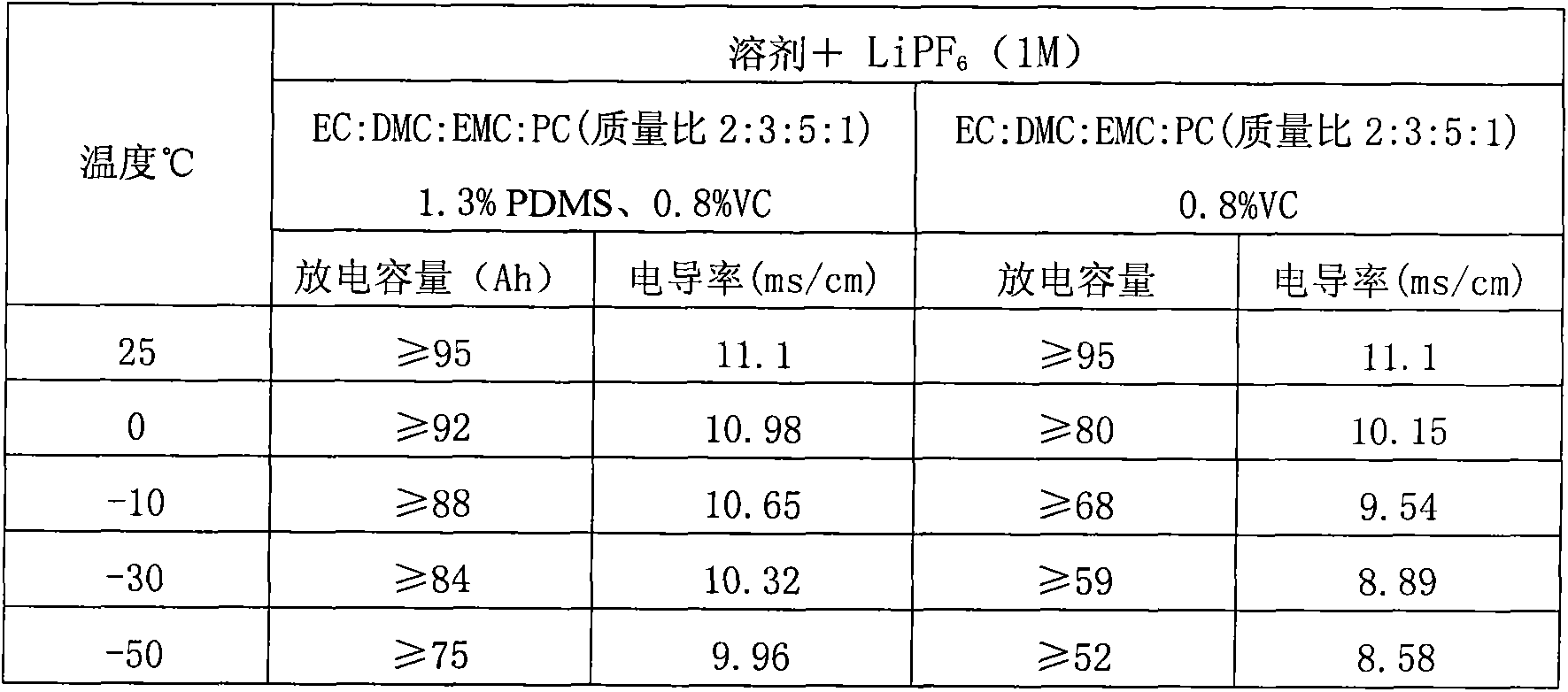

[0026] Additives of 0.8% vinylene carbonate (VC) to ethylene carbonate (EC), dimethyl carbonate (DMC), ethyl methyl carbonate (EMC) and propylene carbonate (PC) improved cycle performance, but Low temperature performance is unchanged. Table 3 is the comparison of the discharge capacity and conductivity of the two electrolytes with two additives and one additive added.

[0027] Table 31mol / L LiPF 6 Discharge capacity and conductivity of electrolytes with the same solvent composition at different additive amounts and different temperatures

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com