centrifugal magnetic drive

A magnetic transmission and centrifugal technology, applied in the transmission device, the device for adjusting the transmission torque, can solve the problems of unstable transmission torque, short service life of the equipment, large size of the magnetic transmission device, etc., and achieve axial installation. The distance is short, the structure is simple and compact, and the effect of saving magnetic material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 single-sided transmission mode

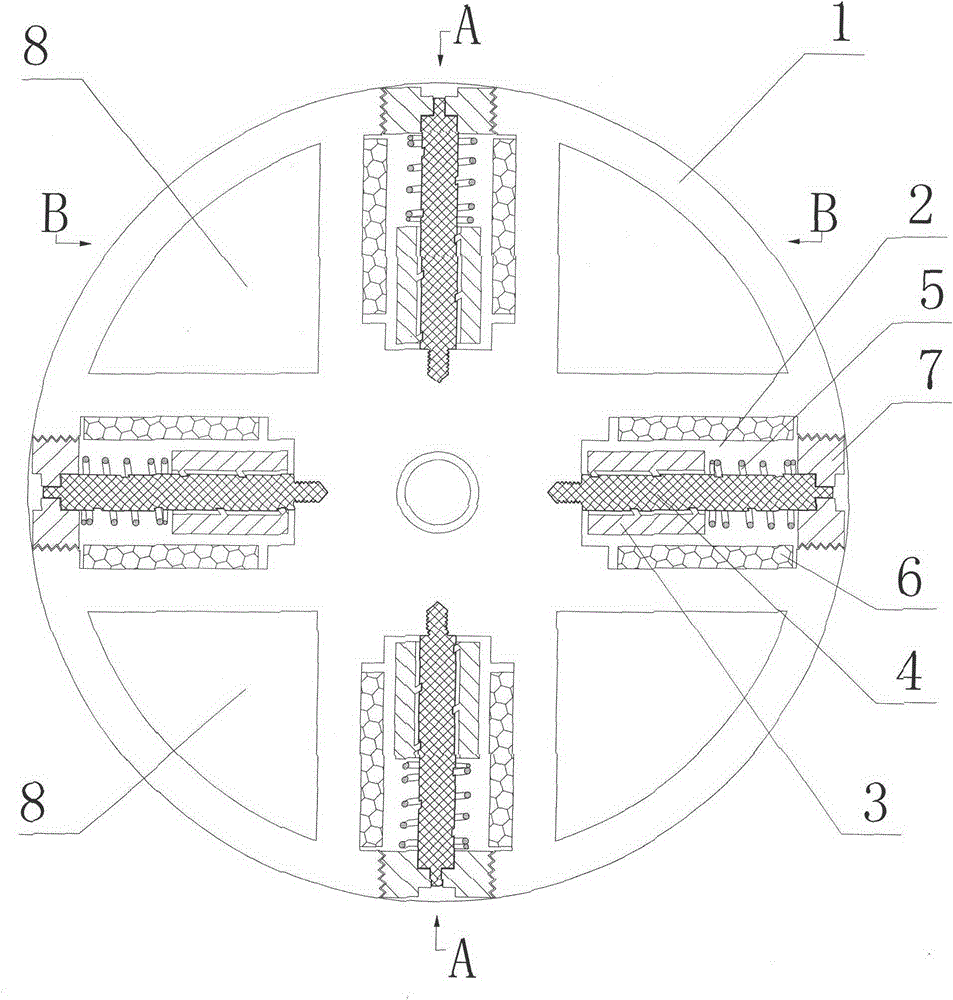

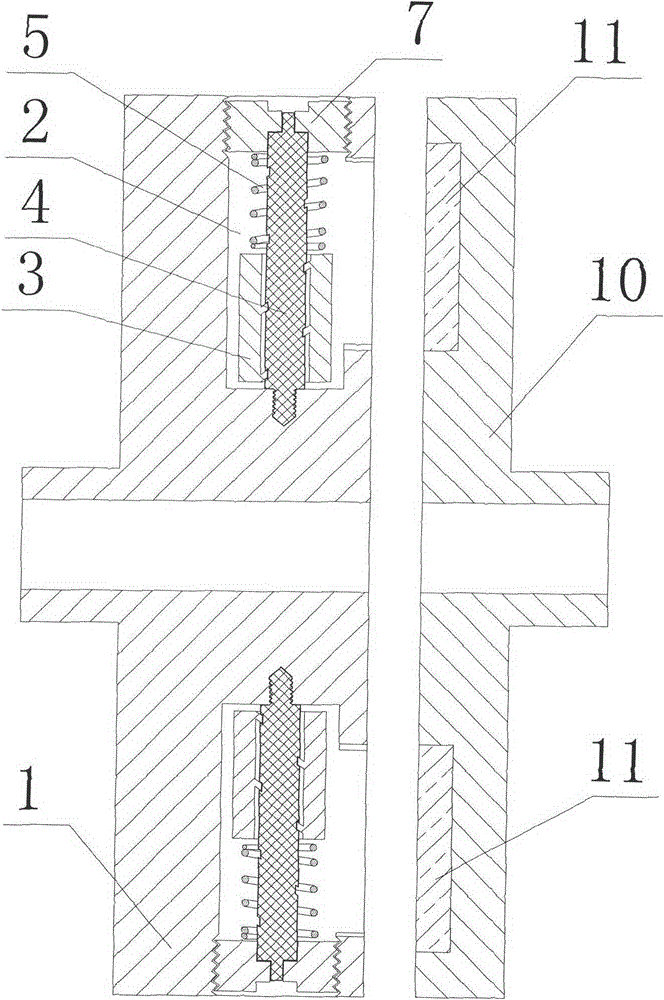

[0039] see figure 1 , 2 , 3, 4, 5 and 10 for the structures represented.

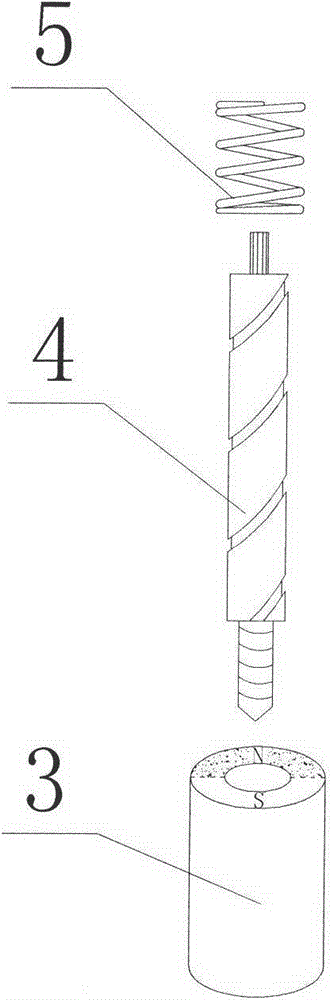

[0040] A centrifugal magnetic transmission device, comprising a driving rotor 1 for connecting an input shaft, a driven rotor 10 for connecting an output shaft, the driving rotor figure 1 There are a number of cavities 2 opened in the radial direction. These cavities 2 are evenly distributed around the axis of the driving rotor. The magnetic drive mechanism components are arranged in the cavities 2. The driven rotor 10 is provided with a conductor ring 11. The material of the conductor ring is selected Metals that conduct electricity well, such as copper or aluminum. see image 3 , wherein the magnetic drive mechanism assembly includes: a magnet 3, a helical spool 4 and a magnet return spring 5, one end of the helical spool 4 placed in the cavity 2 is fixedly connected with the drive rotor 1 in a threaded manner, and the other end of the helical s...

Embodiment 2

[0045] Embodiment 2 double-sided transmission mode

[0046] see figure 1 , 6 and the structure represented in 7.

[0047] On the basis of the basic structure of Embodiment 1, furthermore, a double conductor ring 11 is provided in the driven rotor 10, that is, the driven rotor 10 adopts a cage structure surrounding the driving rotor 1, inside the driven rotor 10, and Conductor rings are arranged on both sides close to the driving rotor 1; Image 6 , and the magnetic poles 6 are open in both directions, which can make the conductor rings on both sides of the driven rotor 10 generate eddy current resistance, which is about twice the torque of the first embodiment, and achieves the purpose of non-contact flexible transmission. The structure of the device Simple, small in size and large in torque, it can generally be used in transmission equipment with medium torque.

Embodiment 3 3

[0048] Embodiment 3 three-sided transmission mode

[0049] see figure 1 , 7 and the structures represented in 8.

[0050] On the basis of Embodiment 2, in order to make full use of the magnetic field of the magnet 3, this embodiment is aimed at the magnetic field along the radial direction of the driving rotor and the outer end surface of the magnet 3. Further, in the driven rotor 10, except for the double-sided conductor ring 11, In the driven rotor, there is also a conductor ring on the side corresponding to the outer end face of the magnet 3, that is, an outer circular conductor ring 12; see Figure 9 , the inside of the magnet 3 is provided with a housing chamber 9 for a magnet return spring; the rotor 1 is driven to rotate, and during the sliding process of the magnet 3 under centrifugal force, the magnet return spring 5 is squeezed and accommodated in the housing chamber 9; so that the outer end of the magnet 3 The distance from the outer circular conductor ring 12 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com