Method for rapidly debitterizing bitter almonds by ultrasound induction

A technology of bitter almonds and ultrasound, applied in the field of rapid debittering of bitter almonds induced by ultrasound, can solve problems such as pollution, long production cycle, and long time, and achieve the effects of easy operation and popularization, reduced labor intensity, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] A method for ultrasonically inducing rapid debittering of bitter almonds, comprising the following steps:

[0033] S1: Raw material handling:

[0034] Select almonds, rinse to remove dust, then heat in a water bath at 90-95°C for 3-5 minutes, then quickly place them in cold water, rub to remove the skin;

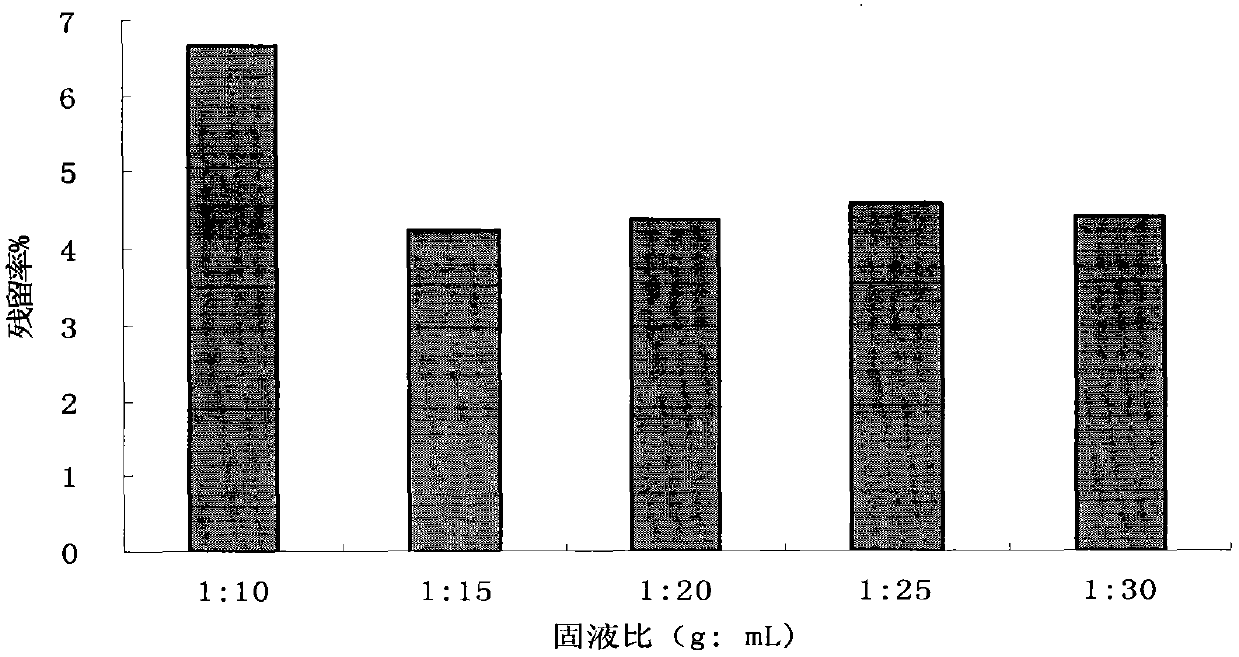

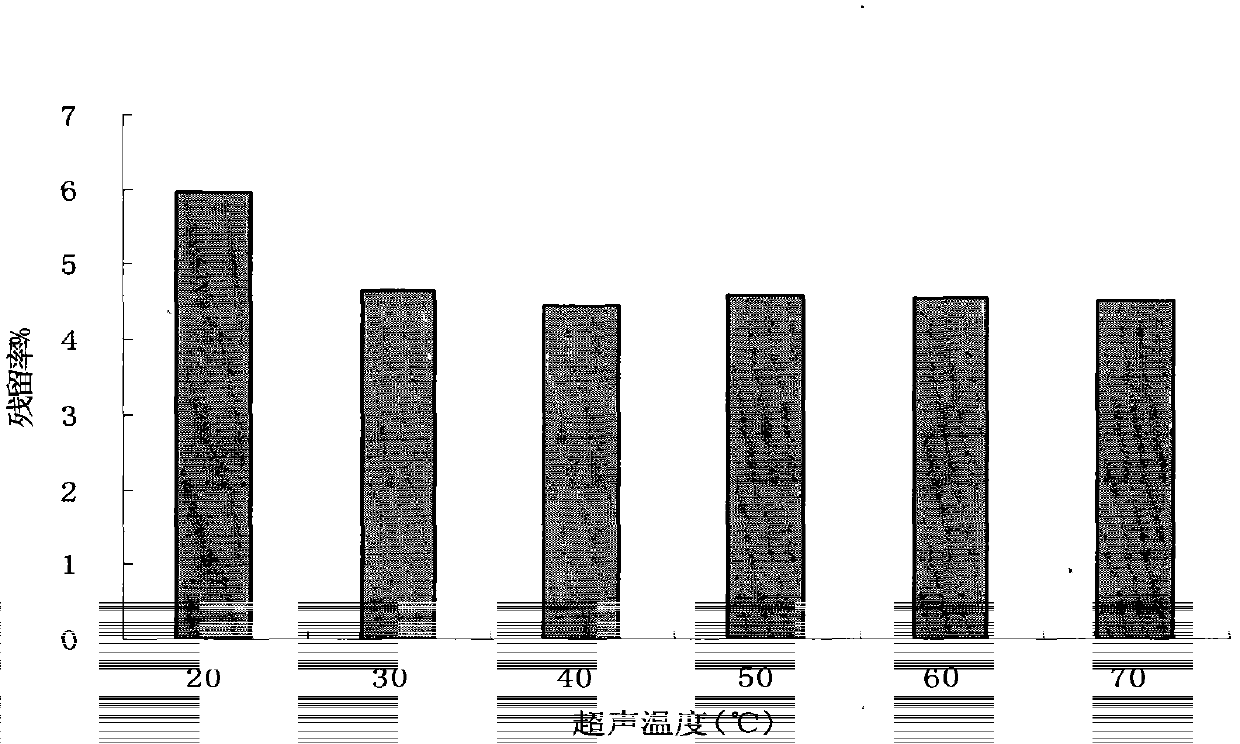

[0035] S2: Put the almonds cleaned and peeled in step S1 into a beaker, add a certain volume of ethanol solution, seal it with a parafilm and place it in an ultrasonic cleaner, set the ultrasonic power, temperature, ultrasonic extraction time, and ultrasonic frequency , Ultrasound to remove bitterness. Wherein, the almond:ethanol ratio is 1:15 (g:mL), the ethanol concentration is 80%, the temperature is 40°C, the time is 120min, the power is 300W, and the frequency is 100kHz.

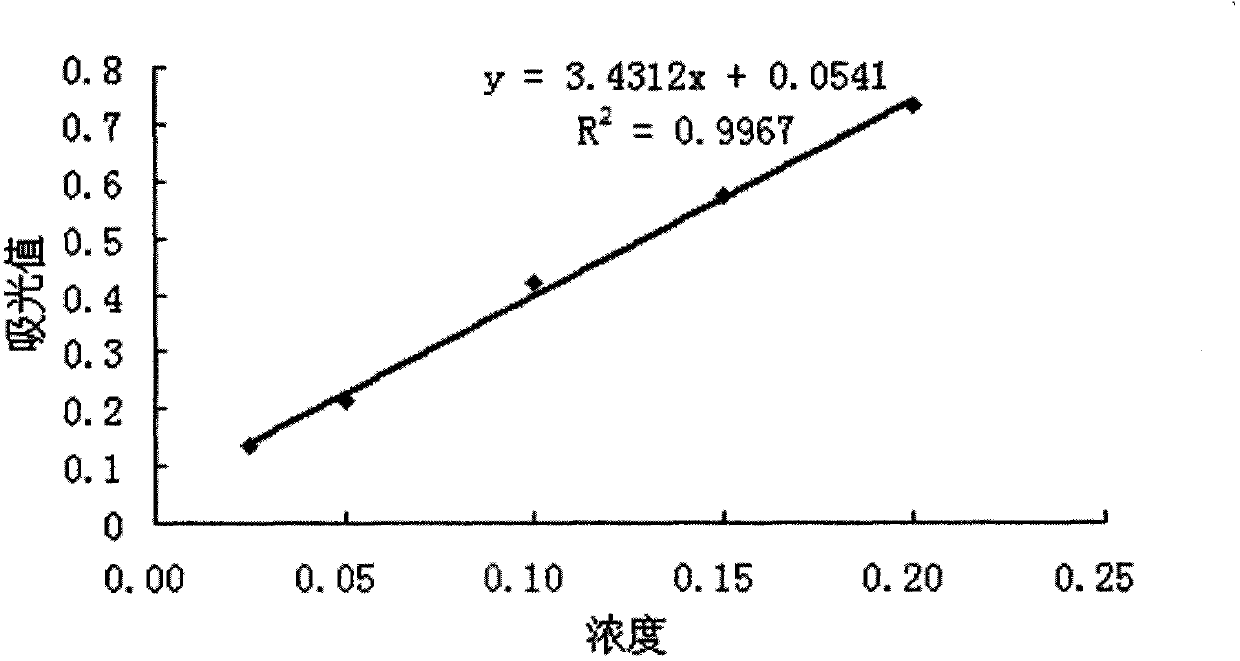

[0036] The following is a description of the method for rapid de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com