Preparation method of Huoxiang Zhengqi capsules

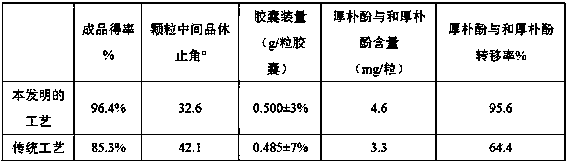

A technology of Huoxiangzhengqi and capsules, which is applied in the directions of capsule delivery, medical preparations containing active ingredients, and pharmaceutical formulations, can solve the problems of difficult operation and low quality controllability of traditional processes, and achieves simplified preparation process steps, The effect of improving production efficiency and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of Huoxiangzhengqi capsules, the raw materials required for every 1000 Huoxiangzhengqi capsules are:

[0020] Patchouli 195g Perilla leaf 65g Angelica dahurica 65g Stir-fried Atractylodes macrocephala 130g

[0021] Chenpi 130g, Pinellia 130g, Magnolia officinalis 130g, Poria cocos 65g

[0022] bellflower 130g licorice 130g big belly skin 65g jujube 32.5g

[0023] Ginger 19.5g Appropriate amount of auxiliary materials;

[0024] The preparation method comprises the following steps:

[0025] (1) Crush Pinellia into fine powder and sieve;

[0026] (2) Steam distill patchouli, perilla leaves, tangerine peel and ginger for 1 hour, collect the distillate, extract volatile oil, and set aside;

[0027] (3) Patchouli, perilla leaves, tangerine peel and ginger are steam-distilled, and the dregs are decocted with 6 times the amount of water of Poria cocos, Dabupi, Platycodon grandiflorum, licorice and jujube for 3 times, each time for 1 hour, and filtered ...

Embodiment 2

[0032] A preparation method of Huoxiangzhengqi capsules, the raw materials required for every 1000 Huoxiangzhengqi capsules are:

[0033] Patchouli 195g Perilla leaf 65g Angelica dahurica 65g Stir-fried Atractylodes macrocephala 130g

[0034] Chenpi 130g, Pinellia 130g, Magnolia officinalis 130g, Poria cocos 65g

[0035] bellflower 130g licorice 130g big belly skin 65g jujube 32.5g

[0036] Ginger 19.5g Appropriate amount of auxiliary materials;

[0037] The preparation method comprises the following steps:

[0038] (1) Crush Pinellia into fine powder and sieve;

[0039] (2) Patchouli, perilla leaves, tangerine peel and ginger were steam distilled for 3 hours, the distillate was collected, and the volatile oil was extracted for later use;

[0040] (3) Patchouli, perilla leaves, tangerine peel and ginger are steam distilled, and the dregs are decocted with Poria cocos, Dabupi, bellflower, licorice and jujube with 12 times the amount of water for 3 hours each time, filtered ...

Embodiment 3

[0045] A preparation method of Huoxiangzhengqi capsules, the raw materials required for every 1000 Huoxiangzhengqi capsules are:

[0046] Patchouli 195g Perilla leaf 65g Angelica dahurica 65g Stir-fried Atractylodes macrocephala 130g

[0047] Chenpi 130g, Pinellia 130g, Magnolia officinalis 130g, Poria cocos 65g

[0048] bellflower 130g licorice 130g big belly skin 65g jujube 32.5g

[0049] Ginger 19.5g Appropriate amount of auxiliary materials;

[0050] The preparation method comprises the following steps:

[0051] (1) Crush Pinellia into fine powder and sieve;

[0052] (2) Patchouli, perilla leaves, tangerine peel and ginger were steam distilled for 2 hours, the distillate was collected, and the volatile oil was extracted for later use;

[0053] (3) Patchouli, perilla leaves, tangerine peel and ginger are steam distilled, and the dregs are decocted with Poria cocos, Dabupi, Campanulaceae, licorice and jujube with 9 times the amount of water, 2 hours each time, filtered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com