A device and method for removing liquefied natural gas mist using a coating screen

A technology of liquefied natural gas and wire mesh, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc., can solve the problems of bulkiness and adding wire mesh, and achieve the effects of reducing volume and weight, increasing turbulence, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

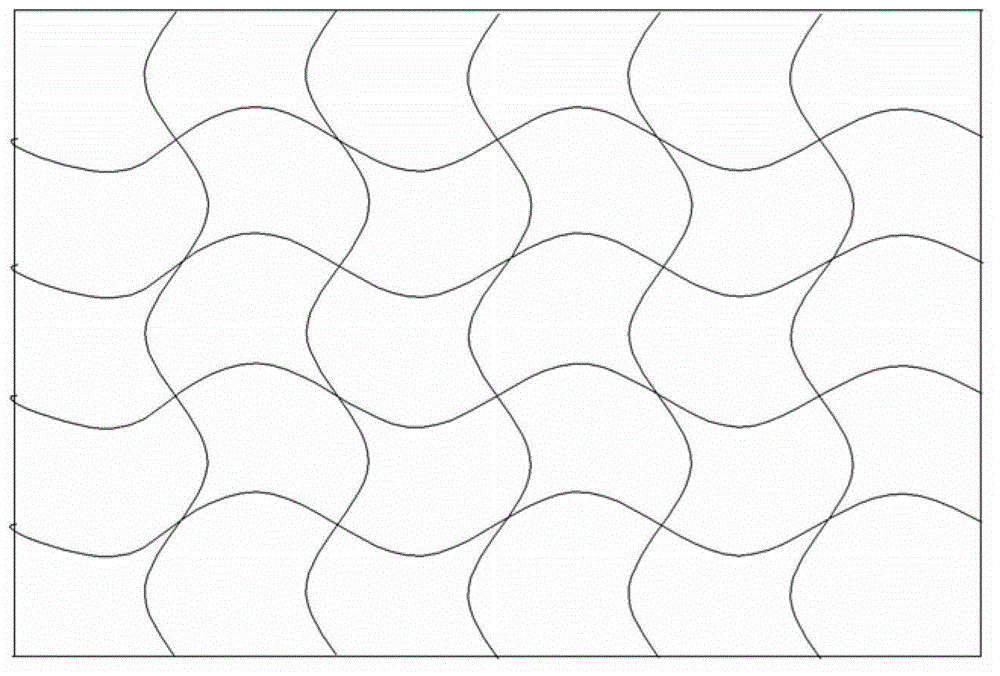

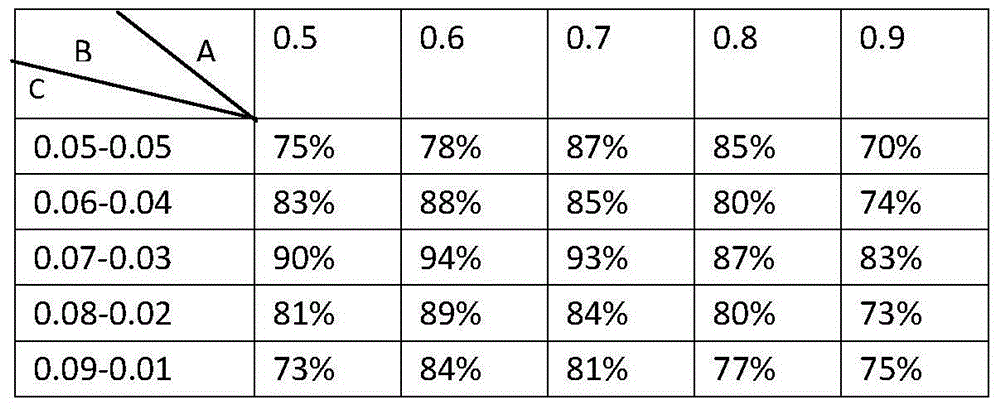

Embodiment 1

[0024]In this embodiment, the liquefied natural gas mist removal device using painted wire mesh is used in a gasification station using an air-temperature gasifier, and the visibility in the station is within 10m, and the gasification scale for LNG is 96000Nm 3 / day (at 20000~100000Nm 3 / weather scale test results are basically the same), the temperature range is ‐162~‐160℃, the pressure range is 0.3~0.5MPa, the gasifier model is VQLNG‐4000 / 16C5, the wire mesh is made of stainless steel 304, the wire mesh The diameter size range is 0.0002m. The height of the screen block is 3m; the coating rate of the coating on the screen in the screen demister is 3m 2 / L; Gradually move the entire wire mesh demister from 0.5m to 0.9m from the air-temperature vaporizer, and calculate the water removal rate respectively; water removal rate = (humidity before measurement - humidity after measurement) / humidity before measurement × 100 %; Humidity before measurement and humidity after measure...

Embodiment 2

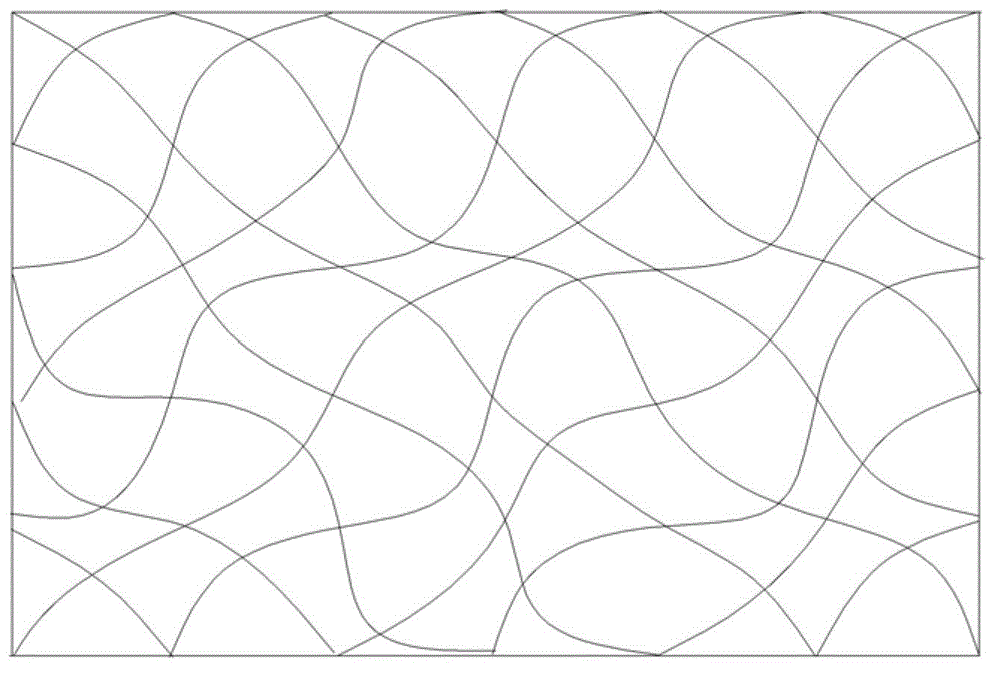

[0029] In this embodiment, the liquefied natural gas mist removal device using painted wire mesh is used in a gasification station using an air-temperature gasifier, and the visibility in the station is within 10m, and the gasification scale for LNG is 96000Nm 3 / day, the temperature range is ‐162~‐160℃, the pressure range is 0.3~0.5MPa, the gasifier model is VQLNG‐4000 / 16C5, the wire mesh is made of stainless steel 304, and the diameter of the wire mesh is 0.00015m. The height of the screen block is 6m; the coating rate of the coating on the screen in the screen demister is 4m 2 / L; Gradually move the entire wire mesh demister from 0.5m to 0.9m from the air-temperature vaporizer, and calculate the water removal rate respectively; water removal rate = (humidity before measurement - humidity after measurement) / humidity before measurement × 100 %; Humidity before measurement and humidity after measurement were measured by Elitech LT‐2 digital temperature and humidity meter. A...

Embodiment 3

[0033] In this embodiment, the liquefied natural gas mist removal device using painted wire mesh is used in a gasification station using an air-temperature gasifier, and the visibility in the station is within 10m, and the gasification scale for LNG is 96000Nm 3 / day, the temperature range is ‐162~‐160℃, the pressure range is 0.3~0.5MPa, the gasifier model is VQLNG‐4000 / 16C5, the wire mesh is made of stainless steel 304, and the diameter of the wire mesh is 0.00015m. The height of the screen block is 5m; the coating rate of the coating on the screen in the screen demister is 5m 2 / L; Gradually move the entire wire mesh demister from 0.5m to 0.9m from the air-temperature vaporizer, and calculate the water removal rate respectively; water removal rate = (humidity before measurement - humidity after measurement) / humidity before measurement × 100 %; Humidity before measurement and humidity after measurement were measured by Elitech LT‐2 digital temperature and humidity meter. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com