Membrane bioreactor

A press-membrane and filter technology, applied in the field of reactors, can solve problems such as unstable permeate flux, lack of permanent retention, unsuitable resistance to tensile stress, etc., and achieve uniform pollution load distribution, improved pollution resistance, and high production efficiency. The effect of water flux stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

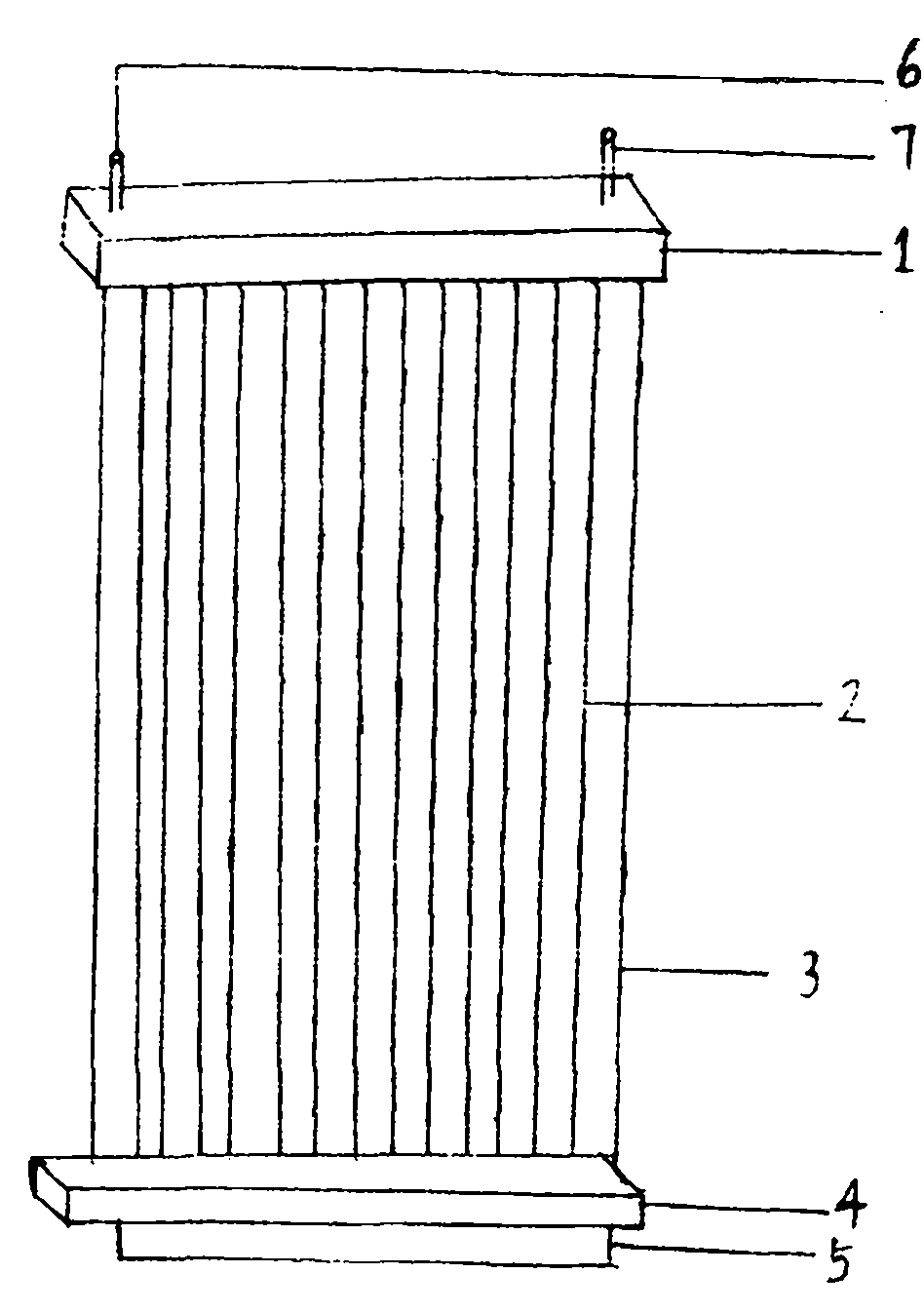

[0007] A membrane bioreactor, comprising an upper frame 1, a hollow fiber tube membrane 2, a support frame 3, a lower frame 4, an aerator 5, and a filtrate port 7, and a support frame 3 is provided between the upper frame 1 and the lower frame 4 , the frame is provided with a hollow fiber tube membrane 2, the upper frame 1 is provided with a filtrate port 7, the backwash port 6 is located next to the filtrate port 7, the lower frame 4 is provided with an aerator 5, and the upper frame 1 has a The filtrate is collected in the main pipe, the hollow fiber tube membrane is provided with membrane filaments, and the air pipe is provided in the support frame. The concentration of the filtrate is 3000 mg per liter of sodium hypochlorite plus a concentration of 1% sodium hydroxide aqueous solution; acids, the concentration is 1 % oxalic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com