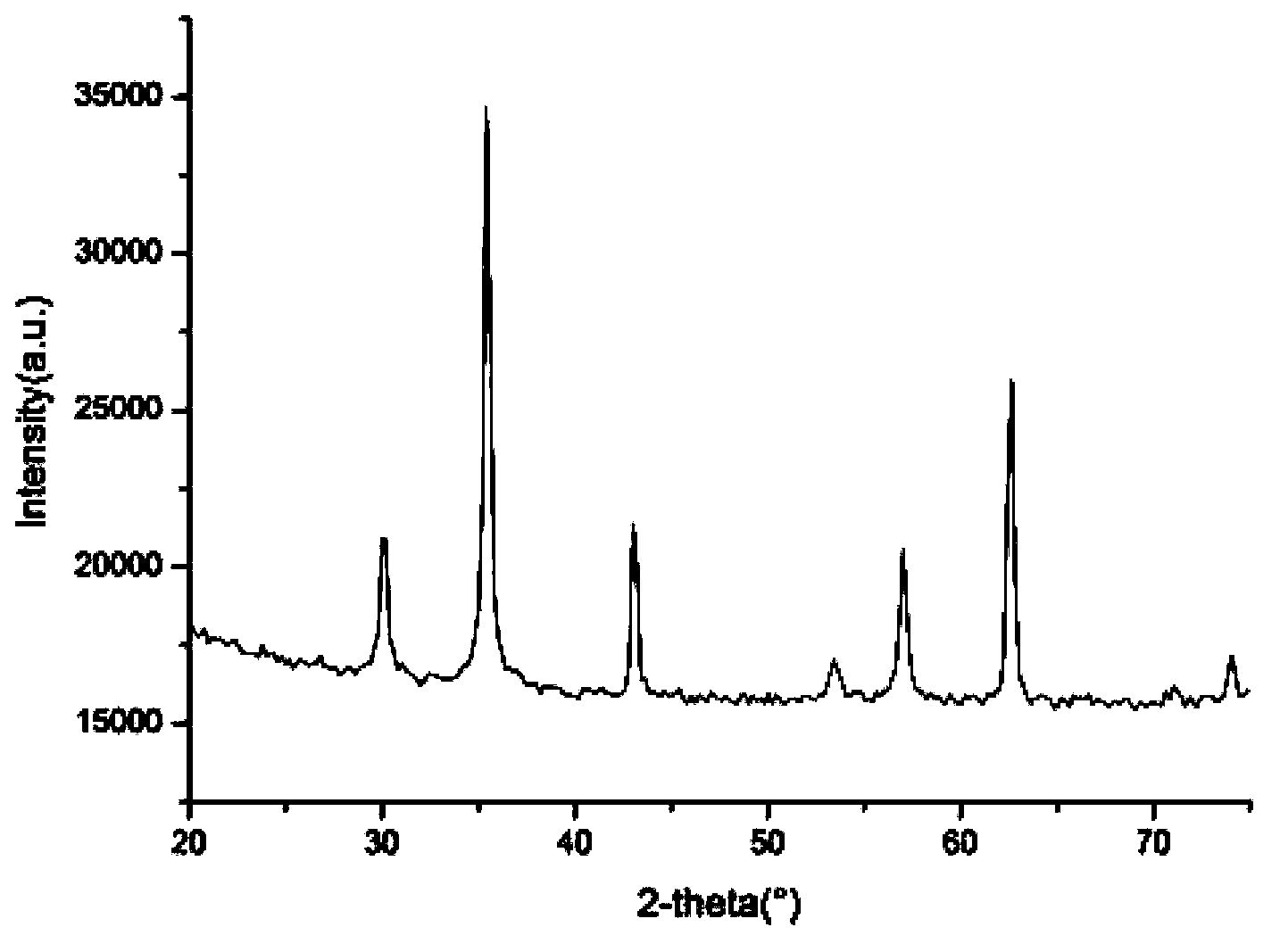

Preparation method of magnesium ferrite nano-particles

A nanoparticle and magnesium ferrite technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as high energy consumption and complicated process, and achieve low energy consumption, simple preparation process, and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

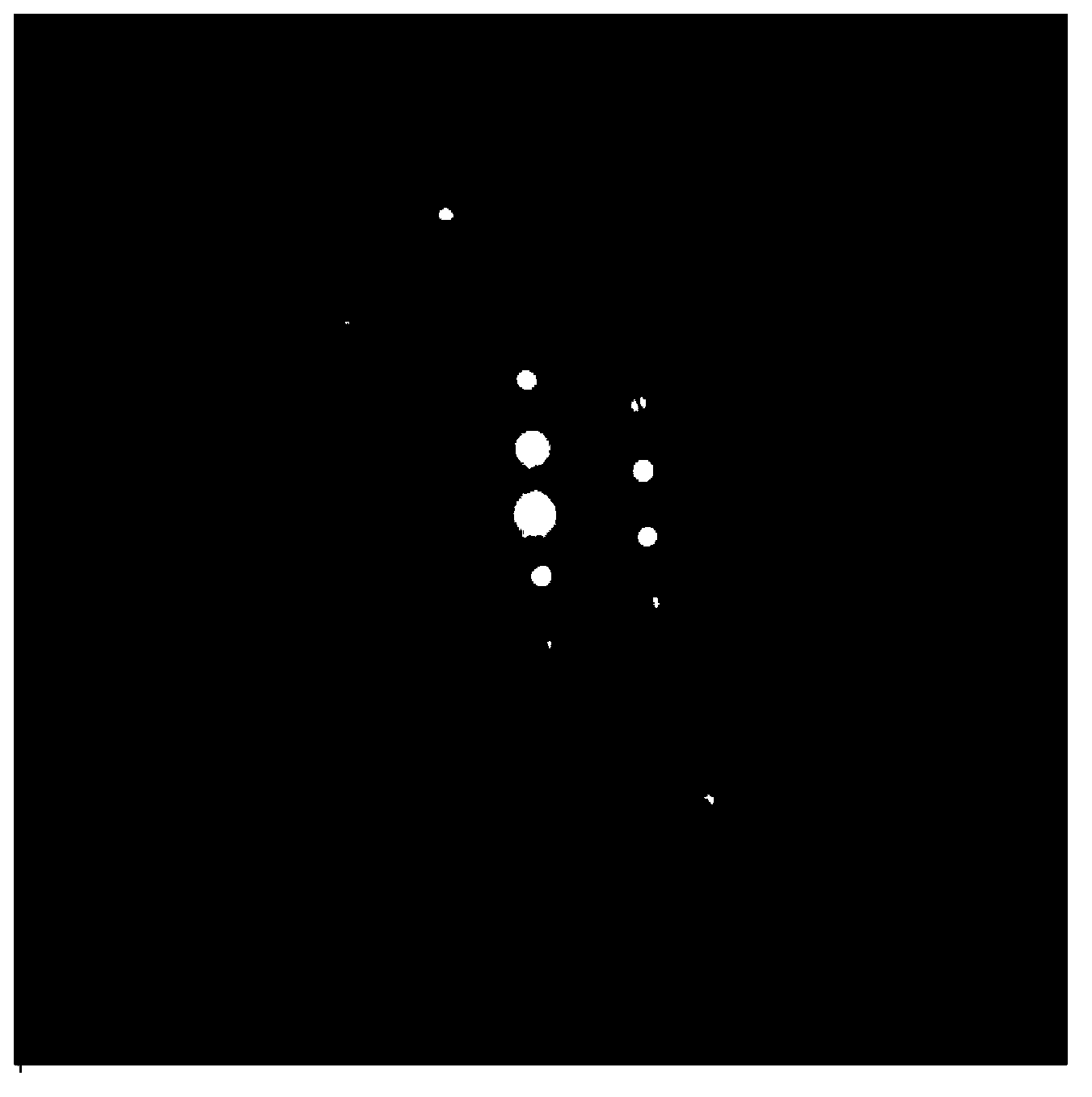

Examples

Embodiment

[0026] A method for preparing magnesium ferrite nanoparticles is adopted, the steps are as follows:

[0027] Step A: 2g of magnesium powder with a purity of 99% is put into a beaker, and the first mixture obtained after adding 50mL of deionized water is placed in an ultrasonic cleaning tank with a frequency of 40kHz and a power of 120W, and is ultrasonically hydrolyzed for 4 hours at normal temperature and pressure After that, a white emulsion colloid is obtained;

[0028] Step B: After drying the white emulsion colloid in a constant temperature drying oven at 80°C, grind it with an agate mortar to obtain Mg(OH) 2 nanoparticles;

[0029] Step C: Weigh Mg(OH) by element content ratio Mg / Fe=1:2 2 Nanoparticles and FeCl 3 ·6H 2 O;

[0030] Step D: the Mg(OH) that will take by weighing 2 The nanoparticles are added to the first beaker with deionized water, and the frequency is 40kHz, the power is 120W, and the ultrasonic cleaning tank is ultrasonically hydrolyzed for 1h; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com