Ceramic body reinforcing agent and application thereof

A green body enhancer and green body technology, which is applied in the production process of sanitary ceramics, can solve the problems of expensive organic body enhancer, great influence on mud fluidity, and influence on mud physical properties, so as to improve the bonding performance , easy to shape, damage improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

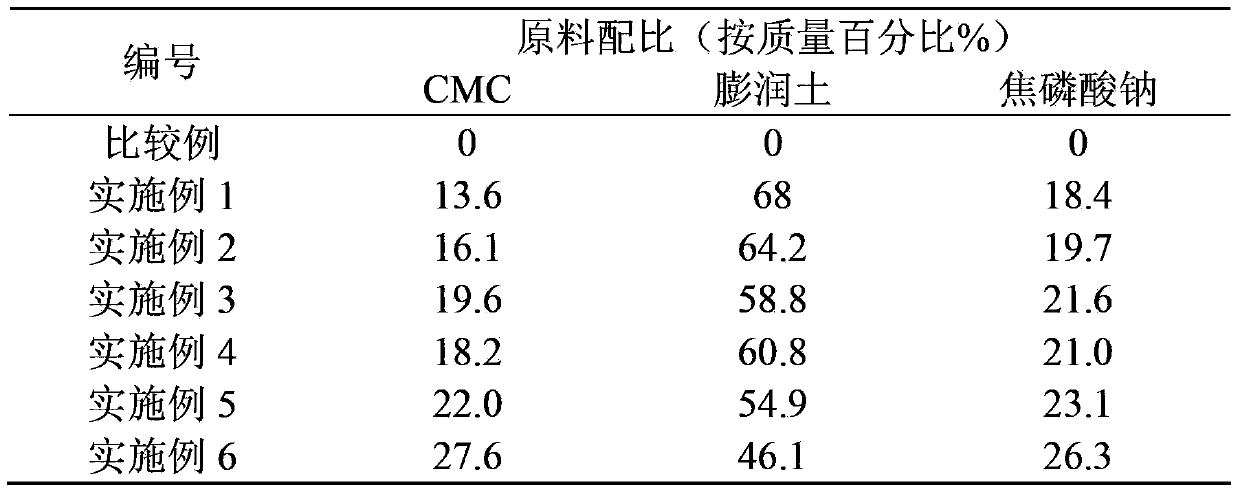

[0014] A body reinforcing agent for sanitary ceramics, the components of which are calculated by mass percentage: 13-28% of a water-soluble high molecular polymer binder, 46-68% of an inorganic binder, and 18-28% of a decoagulant.

[0015] The water-soluble polymer binder is sodium carboxymethylcellulose (CMC).

[0016] The inorganic binder is bentonite.

[0017] The decoagulant is sodium pyrophosphate.

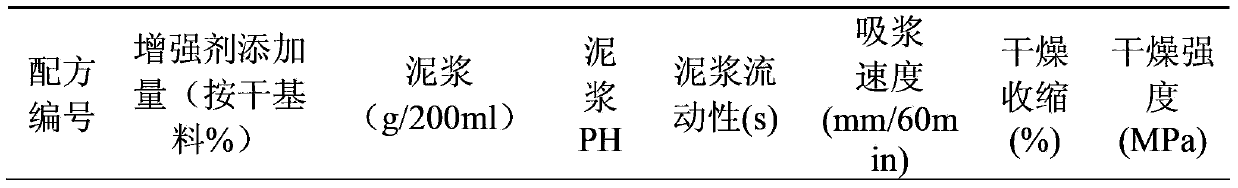

[0018] The manufacturing method of the sanitary ceramic body includes the steps of weighing raw materials, ball milling, slurry preparation, grouting molding, demolding and drying, etc. In the ball milling step, 0.3 to 0.8% of the dry weight of the ceramic blank is added to the above-mentioned reinforcement agent to complete the preparation process.

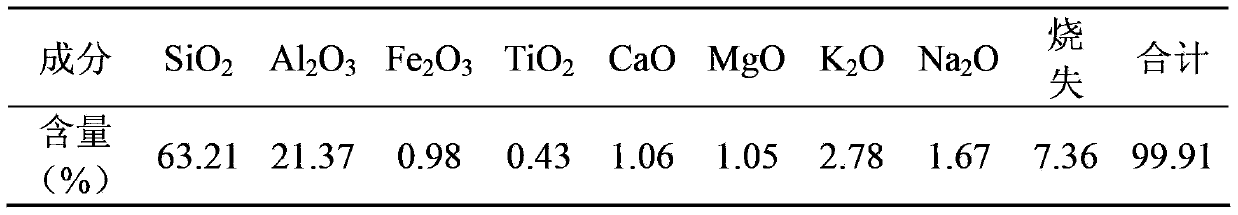

[0019] The chemical composition of the raw materials for the above sanitary ceramic body is shown in Table 1.

[0020] Table 1

[0021]

[0022] Examples of the present invention are provided below, and the raw material p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com