Field order control color liquid crystal display and manufacturing method thereof

A technology for a liquid crystal display and a manufacturing method, which is applied to static indicators, instruments, optics, etc., can solve the problems of low display transmittance and high power consumption, and achieve the effects of improving resolution, reducing heat, and improving light utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

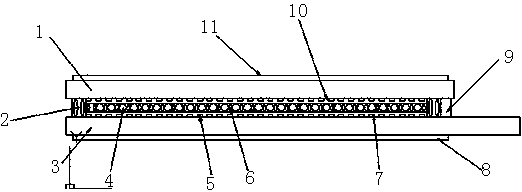

[0018] Control attached figure 1 , monochrome liquid crystal display, its structure includes upper ITO glass 1, frame glue 2, lower ITO glass 3, liner 4, lower ITO layer 5, liquid crystal layer 6, lower vertical alignment film 7, lower polarizer 8, transfer Point 9, the upper vertical alignment film 10, the upper polarizer 11, wherein the upper polarizer 11 and the lower polarizer 8 are respectively attached to the outside of the glass liquid crystal cell, and the glass liquid crystal cell is composed of an upper ITO glass 1 and a lower ITO glass 3 It is made under the fixing of the frame glue 2 and the gasket 4. On the lower ITO layer 5 is the liquid crystal layer 6. There is a transfer point 9 in the frame glue 2. The upper ITO glass 1 is coated with the upper vertical alignment film 10, the lower ITO A lower vertical alignment film 7 is coated on the glass 3, and an upper polarizer 11 and a lower polarizer 8 are respectively pasted on the outside of the glass liquid crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com