Display panel, preparation method of display panel and display device

A display panel and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as hindering the development of narrow-frame products, product yield and reliability impact, etc., to reduce width, reduce production costs, and reduce usage. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] This embodiment also provides a method for manufacturing a display panel, which mainly includes the following steps:

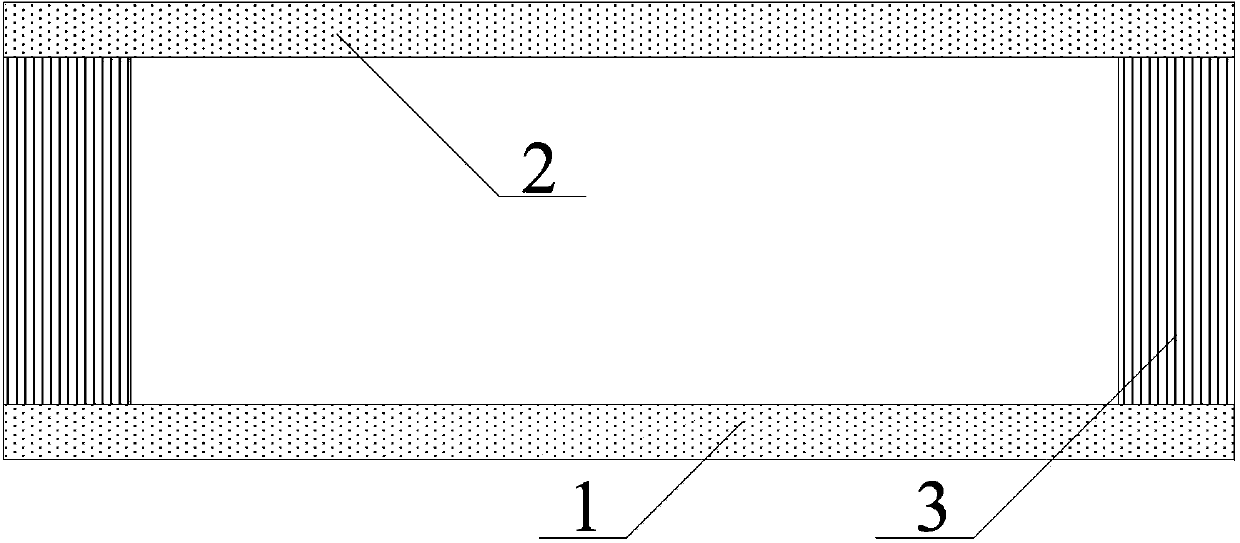

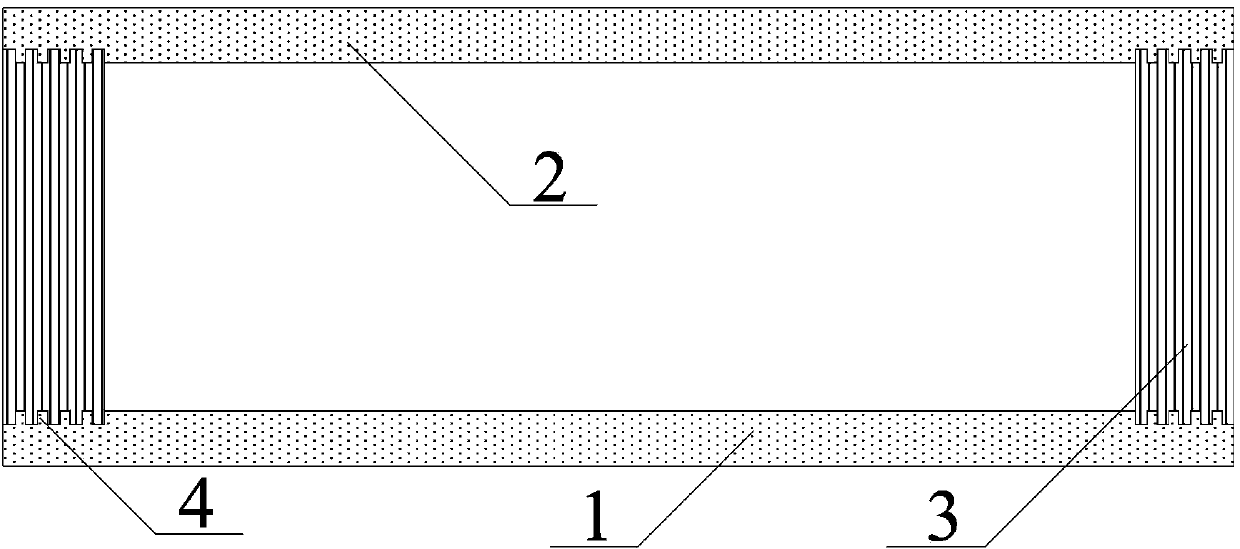

[0044] First, a non-planar structure 4 is formed on the first substrate 1 and the second substrate 2 in the area that needs to be in contact with the sealant 3; the non-planar structure 4 can be formed by a physical method or a chemical method; when the non-planar structure 4 is formed by a physical method , the surface of the first substrate 1 and the second substrate 2 can be roughened by grinding, impacting or other physical methods to form a pitted surface structure, and the surface of the first substrate 1 and the second substrate 2 can also be roughened by cutting or other physical methods Channels are formed on the surface, thereby realizing the stripe structure. When the non-planar structure 4 is formed by chemical methods, corresponding patterns can be formed by means of a surface mask, etc., and the surfaces of the first substrate 1 and the se...

Embodiment 2

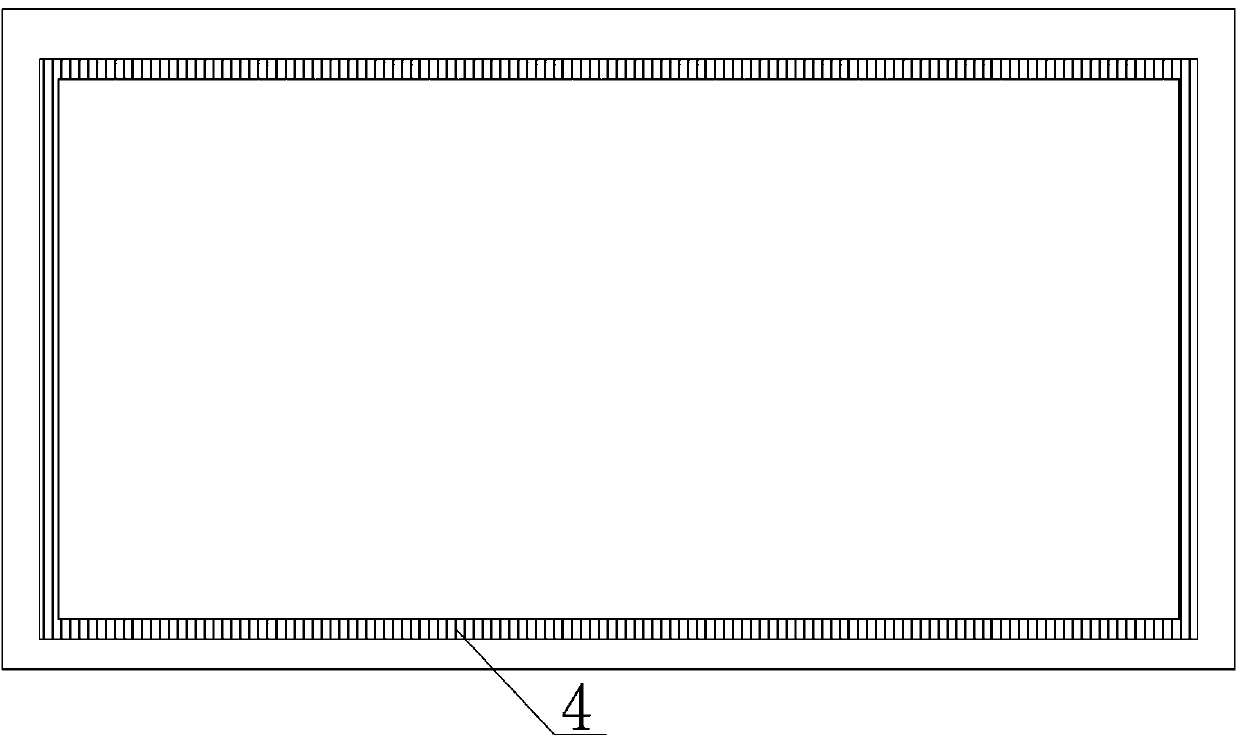

[0047] The display panel provided by this embodiment is as Figure 5 As shown in , it is similar to the structure of the display panel provided in Embodiment 1, that is, a non-planar structure 4 is provided in the area where the first substrate and the second substrate are in contact with the sealant 3; the main difference is that in this embodiment , the above-mentioned non-planar structure is formed during the preparation of the first substrate and / or the second substrate, instead of being directly formed on the first substrate and / or the second substrate after the preparation of the first substrate and / or the second substrate is completed . For example, for a liquid crystal display panel, the first substrate in this embodiment may include a base substrate 11 and a gate metal layer, a gate insulating layer, a source-drain metal layer, a passivation layer, transparent metal layer and protective layer and other functional film layers 12 (of course, the arrangement order of ea...

Embodiment 3

[0086] This embodiment also provides a display device including any one of the above display panels. Since the applied display panel can use a small-width sealant, it can ensure sufficient adhesion between the sealant and the first substrate and the second substrate, so the frame of the display device can be made very narrow; Moreover, due to the reduction of the width of the frame sealant, the usage amount of the frame sealant is reduced to a certain extent, and the production cost of the display device is reduced. The above-mentioned display device may be any product or component with display function such as liquid crystal display panel, electronic paper, OLED (organic light emitting diode) display panel, liquid crystal TV, liquid crystal display, digital photo frame, mobile phone, tablet computer, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com