Microglow discharge ionization source integrated faims

A technology of glow discharge and ionization source, applied in ion source/gun, parts of particle separator tube, material analysis by electromagnetic means, etc., can solve the problems of electric field interference, affecting the stability and sensitivity of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

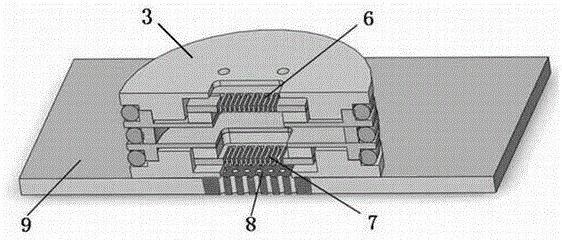

[0029] The structure of microglow discharge ionization source integrated FAIMS described in the present invention is as follows: figure 1As shown, it includes a PCB board 9 and a supporting and fixing board 3, one end of the supporting and fixing board 3 is connected to the PCB board 9, and the other end is an open end, and an air inlet and a power interface are arranged on the open end ; The inside of the fixed support plate is provided with a microglow discharge ionization source 6, a FAIMS chip 7 and a detector 8 sequentially from the open end to the connection end, and the detector 8 is arranged on the PCB board 9, and the The air inlet, the micro-glow discharge ionization source 6 , the FAIMS chip 7 and the detector 8 form a passage through the support and fixing plate 3 and the PCB board 9 . The sample enters the sample channel from the air inlet port, and the sample is ionized by the micro-glow discharge ion source. When the distance between the two electrodes is 50 mic...

Embodiment 2

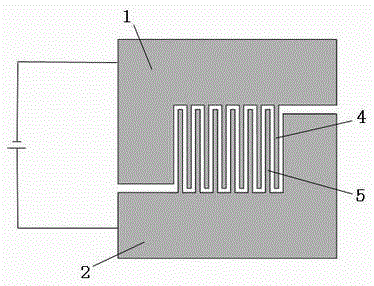

[0031] The micro-glow discharge ionization source 6 in the micro-glow discharge ionization source integrated FAIMS of the present invention is as follows: figure 2 As shown, the microglow ionization source includes positive discharge electrodes 2 and negative discharge electrodes 1, and positive electrode flow guide plates 5 and negative electrode flow guide plates 4 are alternately arranged oppositely between the positive discharge electrodes 2 and negative discharge electrodes 1, Only one end of the positive deflector 5 is connected to the positive discharge electrode 2; only one end of the negative deflector 4 is connected to the negative discharge electrode 1; the positive deflector 5 and the negative deflector 4 to form a continuous channel, the number of the positive discharge electrodes 2 and the negative discharge electrodes 1 can be adjusted according to actual needs, and it is preferably a silicon chip, the thickness of the silicon chip is 0.1-5mm. The most preferre...

Embodiment 3

[0034] A plurality of ion migration channels are etched in the middle of the FAIMS chip 7 in the microglow discharge ionization source integrated FAIMS of the present invention along the longitudinal direction on the silicon wafer. The pitch of each channel is preferably 20-500 microns, and the depth of the channels is preferably 200-3000 microns. An asymmetric radio frequency high voltage is preferably added to the two electrodes of the FAIMS chip 7, and the frequency is preferably 0.2-30 MHz to realize an environment in which high and low electric fields alternately change.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com