Noble-metal protection film and method for forming noble-metal protection film

A precious metal, protective film technology, applied in metal material coating process, device for coating liquid on the surface, liquid chemical plating, etc. Ease of rationalization of production facilities, easy expansion of production scale or effect of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0078] By placing the test pieces A to C in Table 1 in a glove box replaced with dry argon, and immersing them in the liquid glass film-forming composition prepared with the composition of the coating liquid 1 in Table 2, Thus, the glass film-forming composition was coated on the surfaces of the test pieces A to C. Then, in the glove box, using tools such as writing brushes, the film thickness of the liquid coating film was adjusted so that there was no unevenness in the liquid coating film formed on the respective surfaces of the test pieces A to C. to become even.

[0079] Then, the test pieces A to C were taken out from the glove box, and the test pieces A to C were fired at 450° C. under atmospheric pressure for one hour using an electric furnace, and then cooled to obtain Example 1. Precious metal protective films (1)-1 and (1)-3 and reference example (1)-2. In addition, the immersion of the test pieces A to C in the coating liquid 1 was carried out in a state in which ...

Embodiment 2)

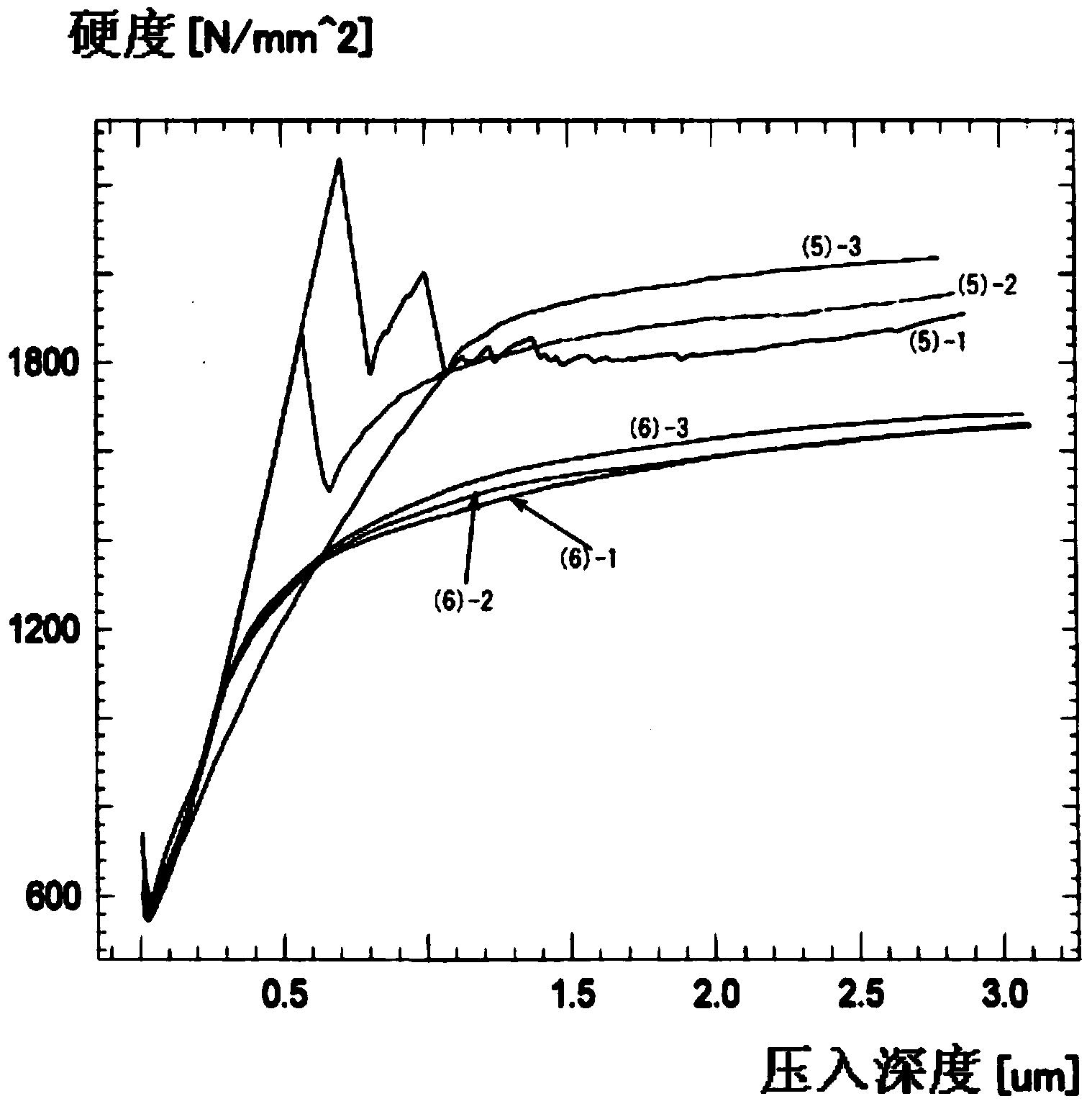

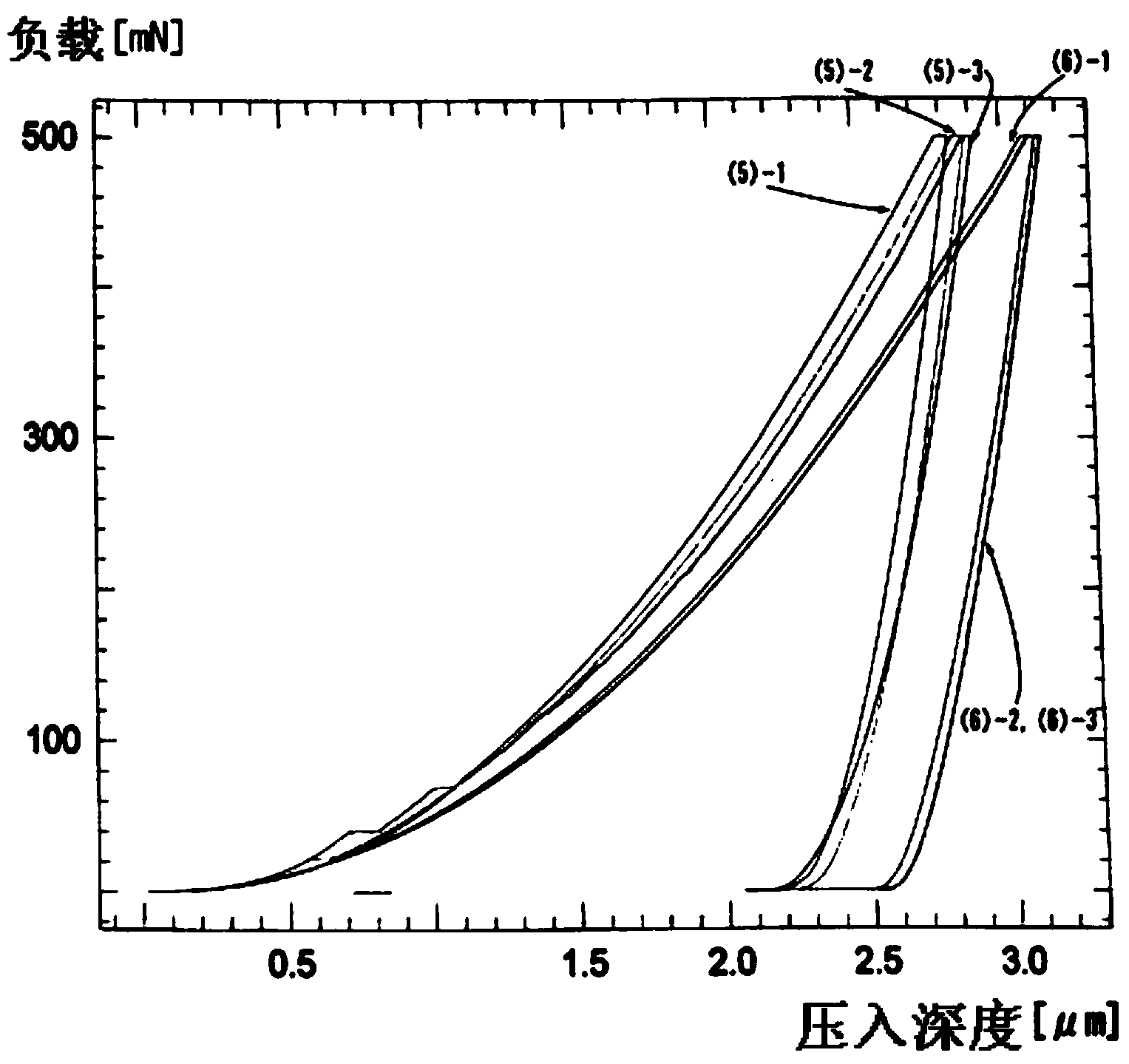

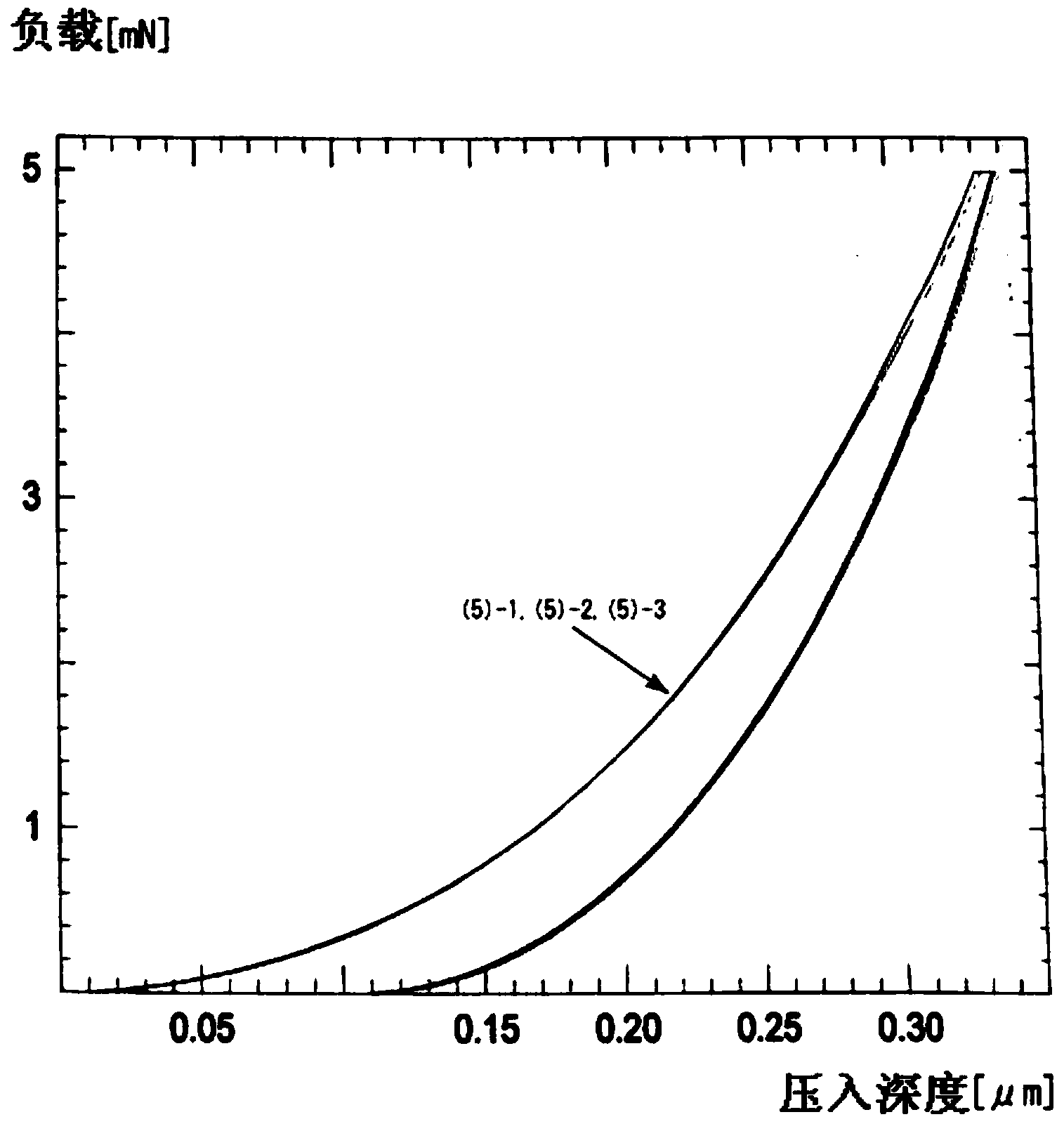

[0083] The noble metal protective films (2)-1, (2)-2 and ( 2)-3. About these protective films, Martens hardness (HM) and Vickers hardness (HV) were measured on the same conditions as Example 1. The results are shown in Table 4.

[0084] [Table 4]

[0085]

Embodiment 3)

[0087] The precious metal protective film (3)-1 of Example 3 was obtained under the same conditions as in Example 1, except that the coating solution 2 in Table 2 was used as the composition for forming a glass film, and the number of times of coating was two. , (3)-2 and (3)-3. About these protective films, Martens hardness (HM) and Vickers hardness (HV) were measured on the same conditions as Example 1. The results are shown in Table 5.

[0088] [table 5]

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com