Method for preparing biological bactericide for fruit trees by utilizing propolis and beewax

A technology of biological fungicides and propolis, which is applied in the field of plant-derived fungicides to achieve the effects of good paste state, enhanced bactericidal efficacy and enhanced immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

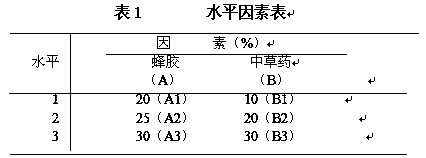

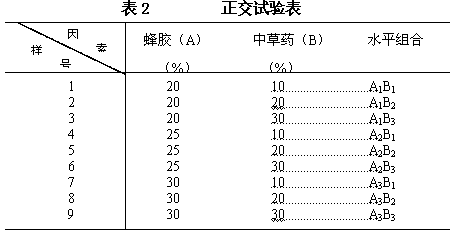

Method used

Image

Examples

Embodiment 1

[0029] ⑴Use 60% concentration of edible ethanol to soak the original wool glue or covering cloth, stir regularly every day to accelerate the dissolution, check the soaking state on the fifth day after soaking, and check the leaching of propolis in wool glue or covering cloth. Soak with 60% edible ethanol for the second time, combine the two soaking liquids; use 0.22% CH 3 COOH solution removes lead. During the vacuum concentration process, the temperature of the material in the concentration tank is controlled at 30°C, the vacuum degree is 0.080 atmospheric pressure, and the water temperature in the interlayer is 65°C. The concentration state of the material is observed through the perspective mirror of the vacuum concentration tank; after 18 hours, the material in the concentration tank boils and jumps. When the dynamic state is moderate, the concentration is stopped, and the interlayer water temperature is kept at 65°C to stew the material for 10 hours to obtain refined propo...

Embodiment 2

[0034] ⑴Use 65% concentration of edible ethanol to soak the original wool glue or covering cloth, stir regularly every day to accelerate the dissolution, check the soaking state on the 6th day after soaking, and check the leaching of propolis in wool glue or covering cloth. Soak with 65% edible ethanol for the second time, combine the two soaking liquids; use 0.24% CH 3 COOH solution removes lead. During the vacuum concentration process, the temperature of the material in the concentration tank is controlled at 40°C, the vacuum degree is 0.084 atmospheric pressure, and the water temperature in the interlayer is 65°C. The concentration state of the material is observed through the perspective mirror of the vacuum concentration tank; after 18 hours, the material in the concentration tank boils and jumps When the state is mild, stop the concentration, keep the interlayer water temperature at 65°C and stew the material for 10 hours to obtain refined propolis;

[0035] (2) Weigh 16...

Embodiment 3

[0039] ⑴Use 70% concentration of edible ethanol to soak the original wool glue or covering cloth, stir regularly every day to accelerate the dissolution, check the soaking state on the 6th day after soaking, and check the leaching of propolis in wool glue or covering cloth. Soak with 70% edible ethanol for the second time, combine the two soaking liquids; use 0.26% CH 3 COOH solution removes lead. During the vacuum concentration process, the temperature of the material in the concentration tank is controlled at 45°C, the vacuum degree is 0.086 atmospheric pressure, and the water temperature in the interlayer is 70°C. The concentration state of the material is observed through the perspective mirror of the vacuum concentration tank; after 19 hours, the material in the concentration tank boils and jumps When the state is mild, stop the concentration, keep the interlayer water temperature at 70°C and stew the material for 11 hours to obtain refined propolis;

[0040] (2) Weigh 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com