Method for determining heat flux density of continuous casting crystallizer based on flux film and air gap dynamic distribution

A technology of continuous casting mold and heat flux, which is applied in the direction of casting equipment, indicating equipment/measuring equipment configuration, manufacturing tools, etc. Accurate description of thermal behavior is difficult and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

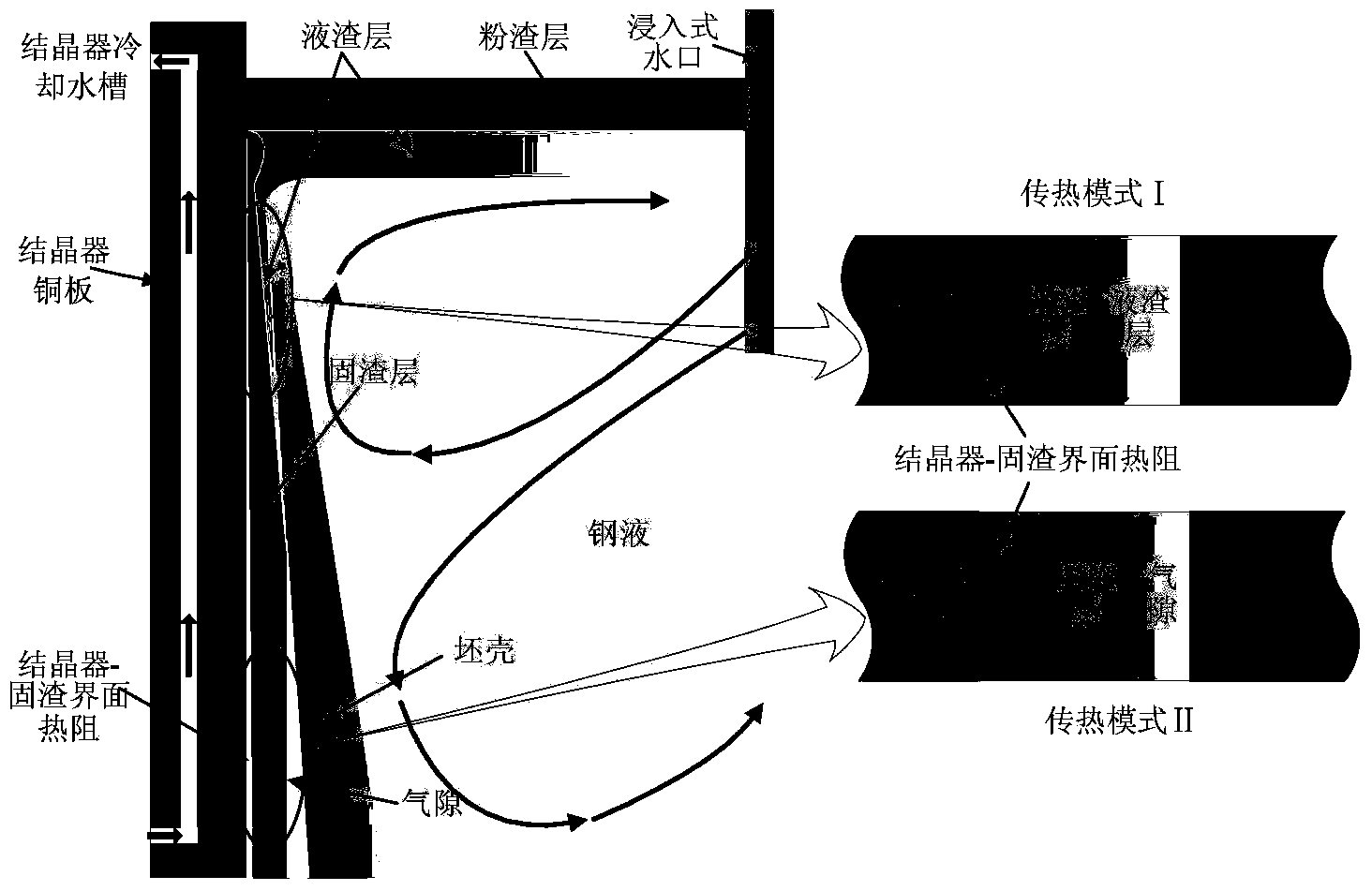

[0060] figure 1 It is a schematic diagram of the solidification heat transfer of the slab shell in the slab crystallizer. In the slab mold, the molten mold slag on the meniscus flows into the slab shell-mold interface under the vibration of the mold to form a mold slag film. Under the cooling effect of the water-cooled copper plate of the crystallizer, the mold powder film solidifies on the side close to the copper plate to form a glass state, and then transforms into a crystalline state. Since the mold slag shrinks during the solidification process, a large interface thermal resistance is formed at the interface between the mold copper plate and the solid slag, that is, the mold-solid slag interface thermal resistance. In the upper part of the mold, due to the high surface temperature of the initially solidified shell, the mold flux near the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com