Method for preparing W-doped Li3V2(PO4)3 powder

A powder and conditional technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of poor high-current discharge performance and low conductivity, and achieve good crystal phase development, high purity, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation of W-doped Li 3 V 2 (PO 4 ) 3 The method of powder, comprises the steps:

[0020] Step 1: Add NH 4 VO 3 Dissolve in deionized water, heat and stir to dissolve, the concentration is 0.03mol / L;

[0021] Step 2: To NH 4 VO 3 Add (NH 4 ) 10 W 12 o 41 , LiOH·H 2 O, citric acid and H 3 PO 4 , under stirring conditions, all the raw materials were dissolved in turn, and mixed evenly, LiOH·H in the solution 2 O, NH 4 VO 3 , (NH 4 ) 10 W 12 o 41 、H 3 PO 4 The molar ratio with citric acid is 3:1.95:(0.05 / 12):3:1.5;

[0022] Step 3: Put the beaker containing the above mixed solution into a water bath at 80°C, and stir for 10 hours to obtain a dark blue gel;

[0023] Step 4: Put the dark blue gel-like product in an oven at 90°C, dry it completely and grind it into powder;

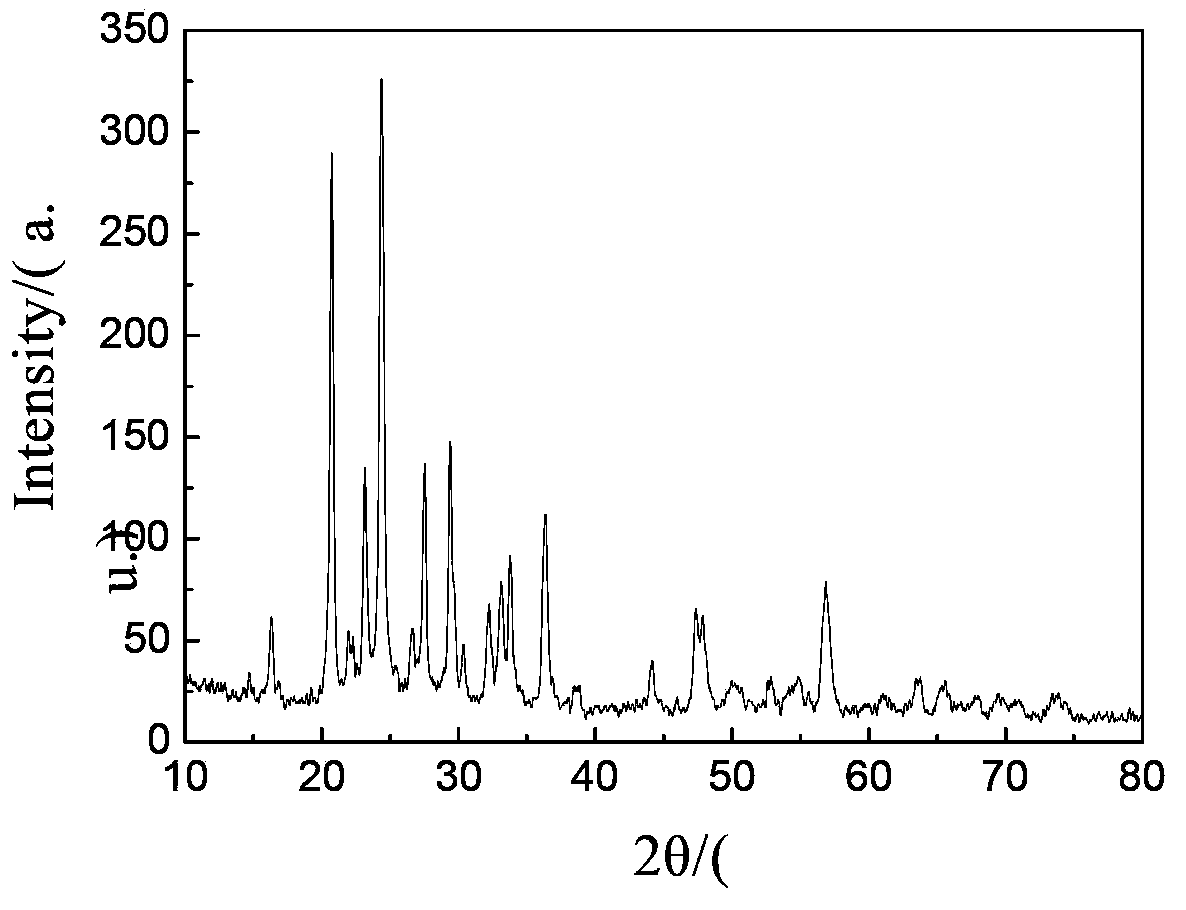

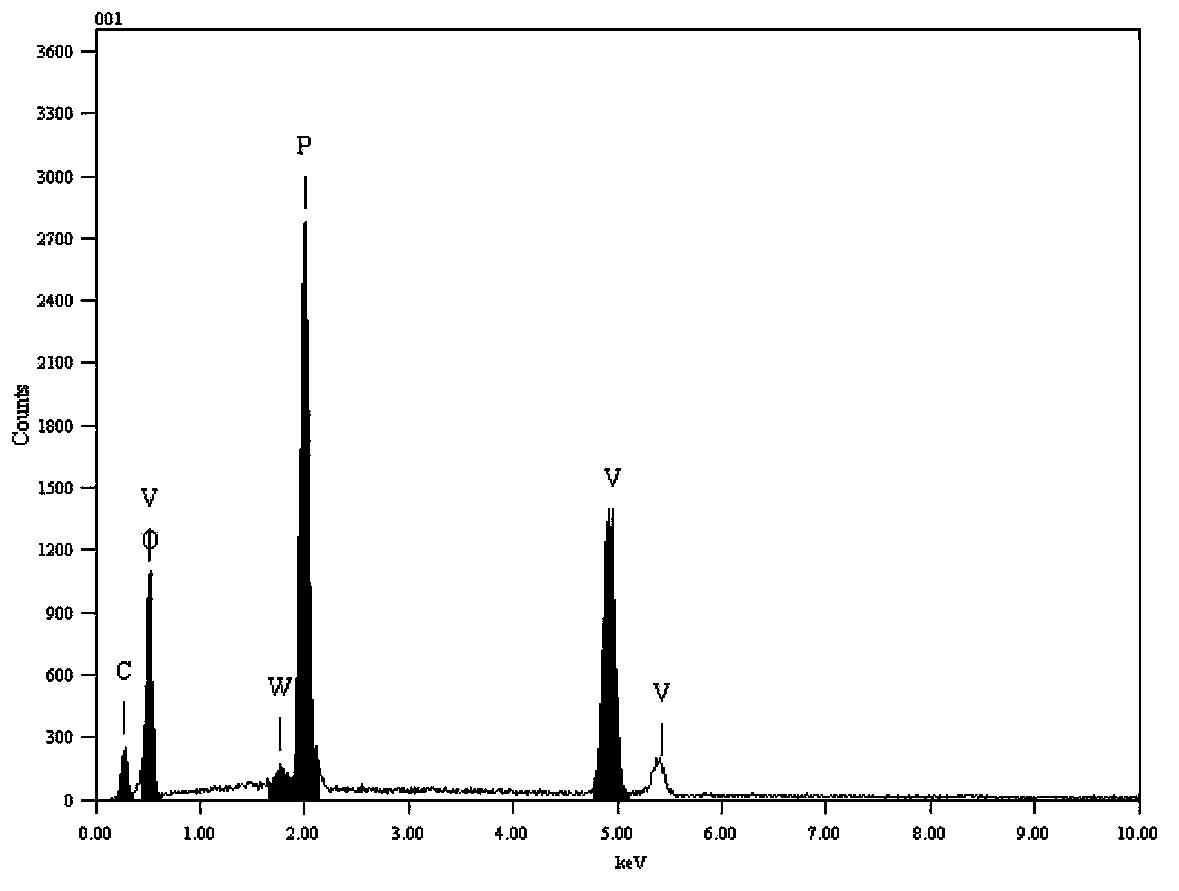

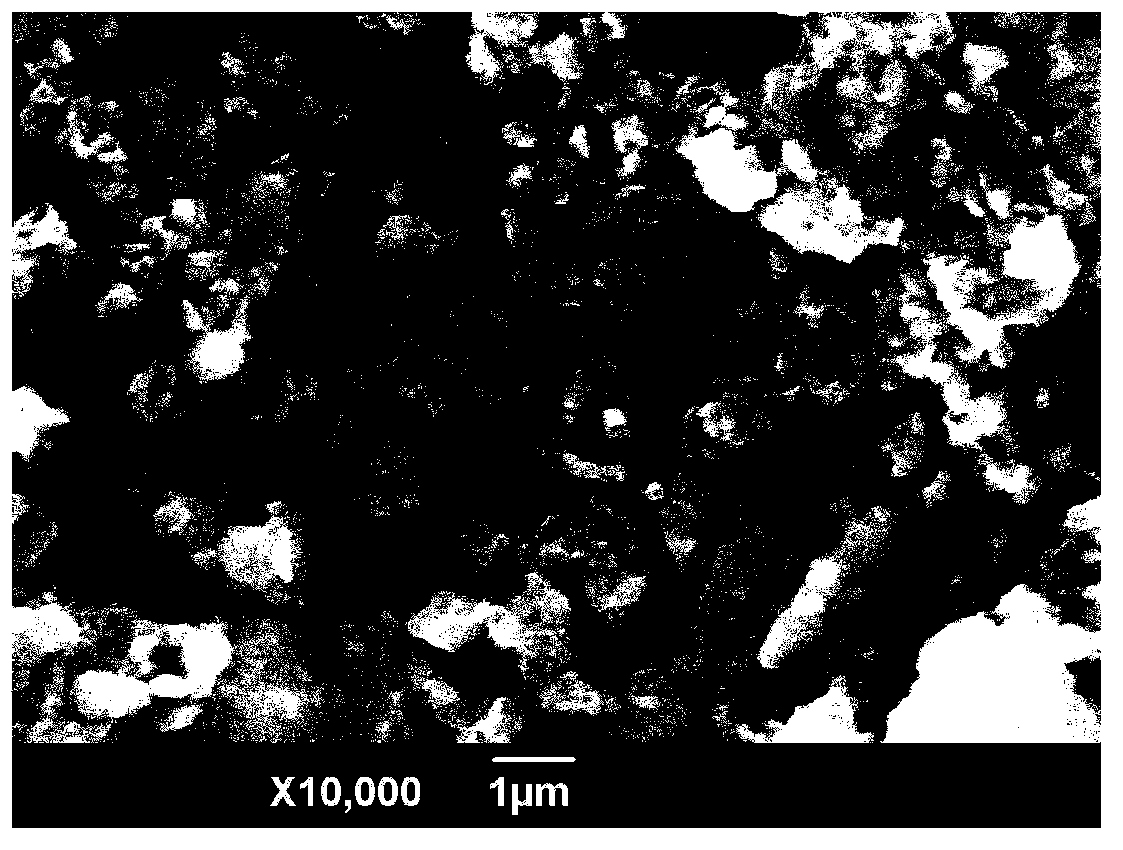

[0024] Step 5: Put the obtained powder in N 2 Calcined at 700 °C for 12 h under protected conditions to obtain W-doped Li 3 V 2 (PO 4 ) 3 Powder——Li 3 V 1.95 W 0.05 ...

Embodiment 2

[0029] A preparation of W-doped Li 3 V 2 (PO 4 ) 3 The method of powder, comprises the steps:

[0030] Step 1: Add NH 4 VO 3 Dissolve in deionized water, heat and stir to dissolve, and its concentration is 0.08mol / L;

[0031] Step 2: To NH 4 VO 3 Add (NH 4 ) 10 W 12 o 41 , LiOH·H 2 O, citric acid and H 3 PO 4 , under stirring conditions, all the raw materials were dissolved in turn, and mixed evenly, LiOH·H in the solution 2 O, NH 4 VO 3 , (NH 4 ) 10 W 12 o 41 、H 3 PO 4 The molar ratio with citric acid is 3:1.85:(0.15 / 12):3:1.5;

[0032] Step 3: Put the beaker containing the above mixed solution into a water bath at 90°C, and stir for 15 hours to obtain a dark blue gel;

[0033] Step 4: Put the dark blue gel-like product in an oven at 90°C, dry it completely and grind it into powder;

[0034] Step 5: Put the obtained powder in N 2 Calcined at 850 °C for 4 h under protected conditions to obtain W-doped Li 3 V 2 (PO 4 ) 3 Powder——Li 3 V 1.85 W 0....

Embodiment 3

[0036] A preparation of W-doped Li 3 V 2 (PO 4 ) 3 The method of powder, comprises the steps:

[0037] Step 1: Add NH 4 VO 3 Dissolve in deionized water, heat and stir to dissolve, the concentration is 0.06mol / L;

[0038] Step 2: To NH 4 VO 3 Add (NH 4 ) 10 W 12 o 41 , LiOH·H 2 O, citric acid and H 3 PO 4 , under stirring conditions, all the raw materials were dissolved in turn, and mixed evenly, LiOH·H in the solution 2 O, NH 4 VO 3 , (NH 4 ) 10 W 12 o 41 、H 3 PO 4 The molar ratio to citric acid is 3:1.99:(0.01 / 12):3:1.5;

[0039] Step 3: Put the beaker containing the above mixed solution into a water bath at 85°C, and stir for 12 hours to obtain a dark blue gel;

[0040] Step 4: Put the dark blue gel-like product in an oven at 90°C, dry it completely and grind it into powder;

[0041] Step 5: Put the obtained powder in N 2 Calcined at 800 °C for 8 h under protected conditions to obtain W-doped Li 3 V 2 (PO 4 ) 3 Powder——Li 3 V 1.99 W 0.01 (PO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com