Multi-grade activated carbon sintered filter element and manufacturing method thereof

A technology of sintered filter element and activated carbon, which is applied in the field of water purifier filter element, can solve the problems of no filtering function, low filter element service life and insignificant effect, etc., and achieves good dechlorination effect, high product filtration accuracy and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

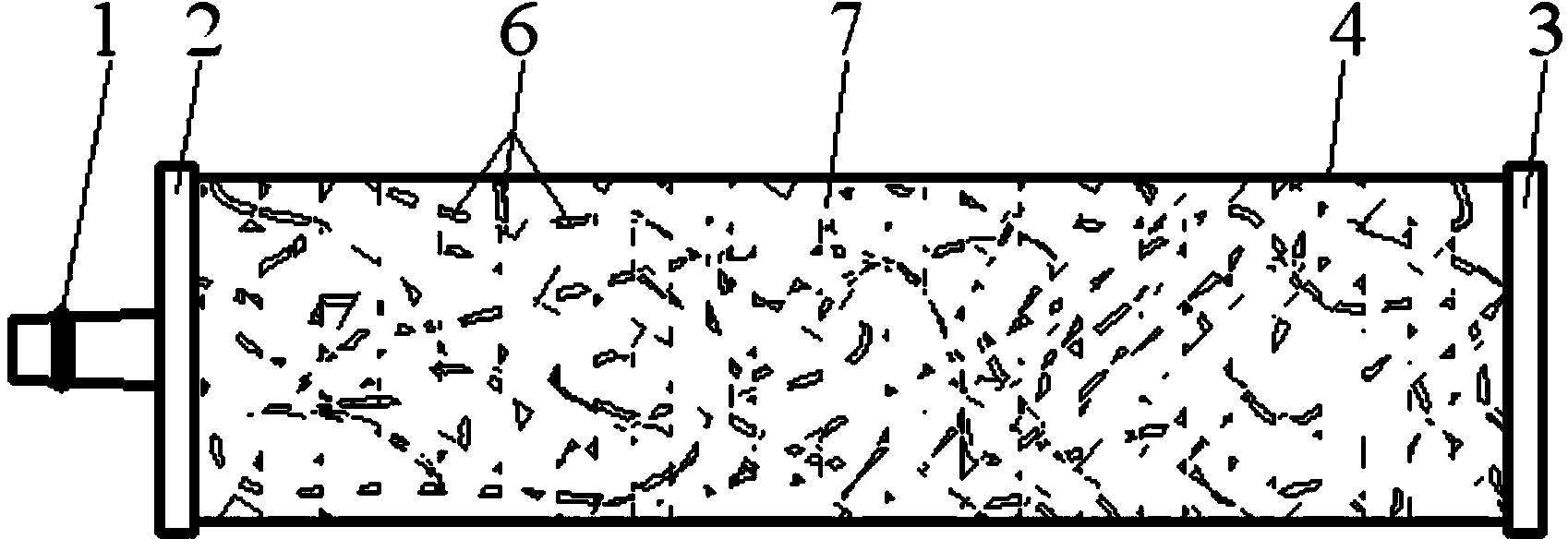

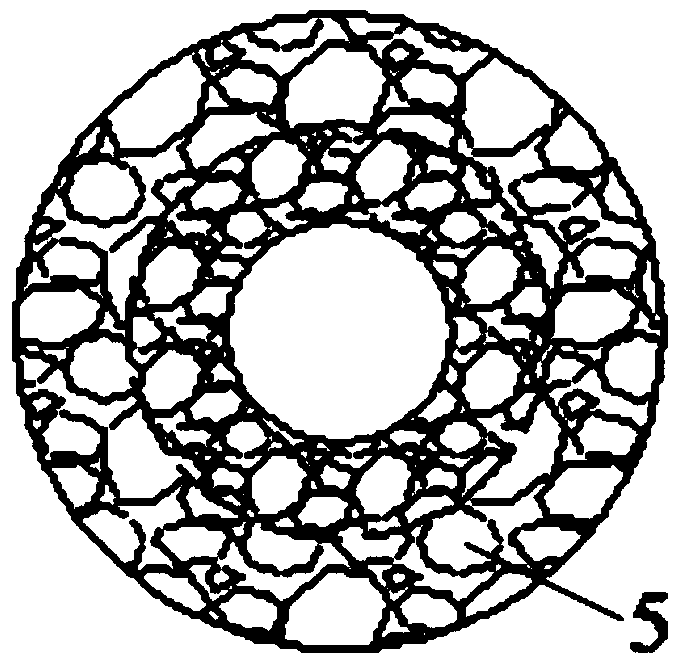

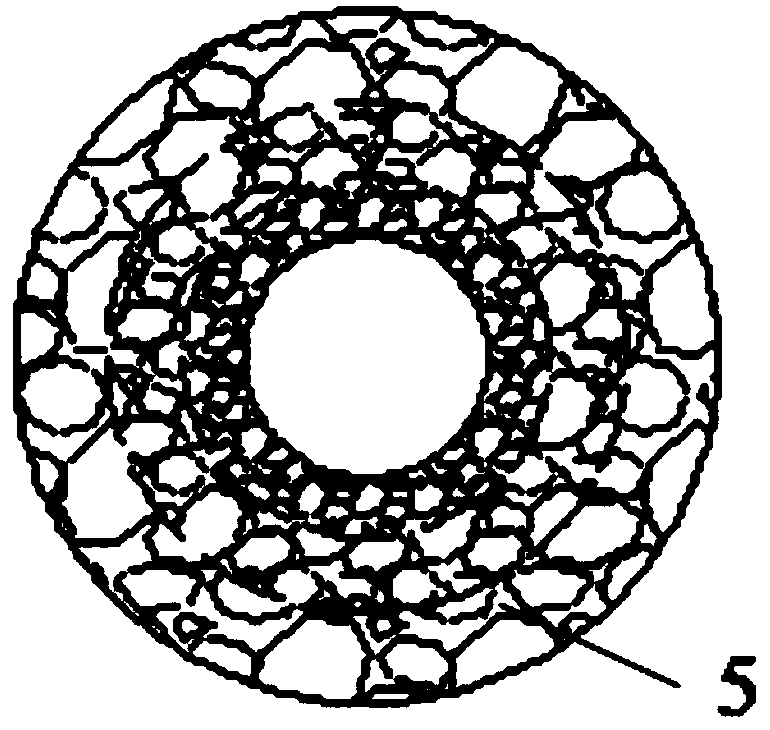

[0030] The filter element includes a first plastic end cap 2, a second plastic end cap 3, a vulcanized rubber ring 1, a fiber membrane and a filter cartridge 4. One end of the filter cartridge 4 is connected to the first plastic end cap 2, and the other end is connected to the second plastic end cap. The plastic end cap 3 is connected, the vulcanized rubber ring 1 is installed on the first plastic end cap 2, the filter cartridge 4 includes 2 layers of filter layers, and the filter layer 5 is made of activated carbon powder of different particle sizes and KDF filter material of different particle sizes A filter layer 5 made by mixing and sintering ultra-high molecular weight polyethylene powder, the cross-section of the filter layer 5 is two coaxial rings with different inner diameters, and the particle size of the outer filter layer 5 is larger than that of the inner filter layer 5 , hereinafter referred to as a high-efficiency sintered activated carbon powder filter element fo...

Embodiment 2

[0033] The filter element includes a first plastic end cap 2, a second plastic end cap 3, a vulcanized rubber ring 1, a fiber membrane and a filter cartridge 4. One end of the filter cartridge 4 is connected to the first plastic end cap 2, and the other end is connected to the second plastic end cap. The plastic end cap 3 is connected, the vulcanized rubber ring 1 is installed on the first plastic end cap 2, and the filter cartridge 4 includes 3 layers of filter layers 5, and the filter layer 5 is made of activated carbon powder of different particle sizes and KDF filter layer of different particle sizes. Material and ultra-high molecular weight polyethylene powder mixed and sintered filter layer 5, the cross-section of the filter layer 5 is three coaxial rings with different inner diameters, the outer filter layer 5 particle size is larger than the inner filter layer 5 Particle size, hereinafter referred to as the high-efficiency sintered activated carbon powder filter element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com