High-efficiency treatment and recycling method of chemical industry wastewater and biochemical effluent

A technology for biochemical effluent and chemical wastewater, applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, adsorption water/sewage treatment, etc. The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

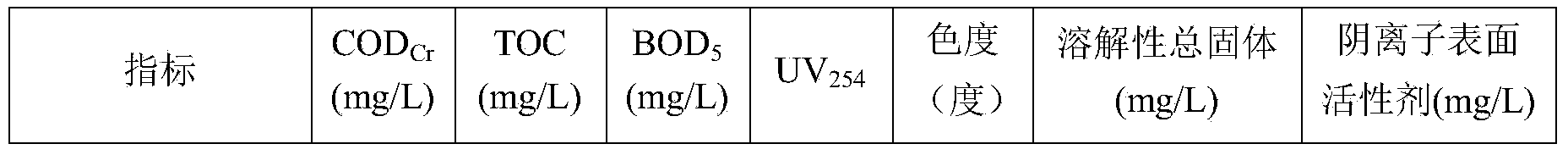

Embodiment 1

[0025] The water quality of biochemical effluent from a large chemical wastewater treatment plant is shown in Table 1. After adjusting the pH value to 5.5, ferrous sulfate and hydrogen peroxide were sequentially added to the water sample for Fenton oxidation to make Fe 2+ Concentration is 3mmol / L, H 2 o 2 The concentration is 5mmol / L, and the reaction time is 300 minutes. Fenton’s oxidized water reacts with amino-modified magnetic ultra-high cross-linked composite functional resins (resins in Examples 1-9, all of which are disclosed in the patent literature with the patent application number 201310106265.5) accounting for 4% of the water volume, After reacting for 800 minutes, solid-liquid separation was carried out. The quality of the effluent after separation is shown in Table 1. Regenerate with a desorption solution containing 6wt.% sodium hydroxide and 80wt.% methanol, and the regeneration time is 150 minutes. Regenerated resin continues to react as fresh resin. The ...

Embodiment 2

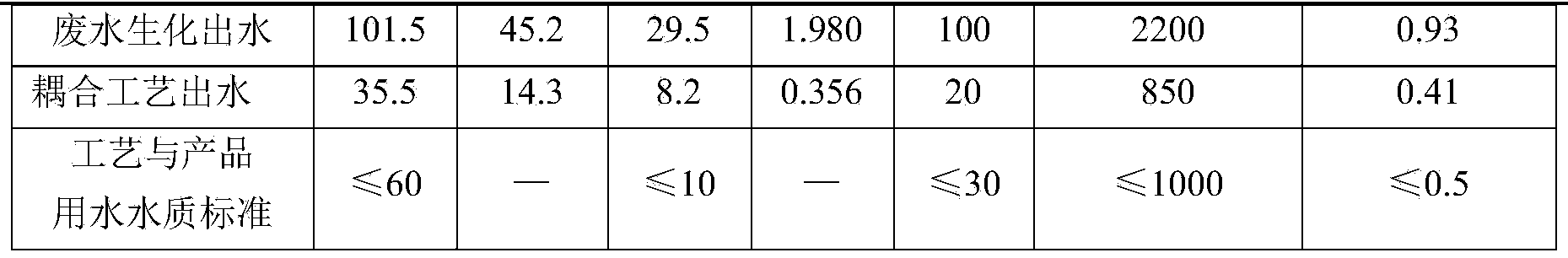

[0030] The water quality of the biochemical effluent of a medium-sized chemical wastewater treatment plant is shown in Table 2. After adjusting the pH value to 6, ferrous sulfate and hydrogen peroxide were sequentially added to the water sample for Fenton oxidation to make Fe 2+ Concentration is 2.5mmol / L, H 2 o 2 The concentration is 4mmol / L, and the reaction time is 600 minutes. The Fenton oxidation effluent was reacted with amino-modified magnetic ultra-high cross-linked composite functional resin accounting for 2% of the water volume, and after 600 minutes of reaction, solid-liquid separation was carried out. The quality of the effluent after separation is shown in Table 2. Regenerate with a desorption solution containing 10wt.% sodium hydroxide and 70wt.% methanol, and the regeneration time is 180 minutes. Regenerated resin continues to react as fresh resin. The wastewater from the plant complies with the recycled water reuse standard, and is listed in Table 2 with r...

Embodiment 3

[0034]The water quality of the biochemical effluent of a medium-sized chemical wastewater treatment plant is shown in Table 3. After adjusting the pH value to 7, ferrous sulfate and hydrogen peroxide were added to the water sample for Fenton oxidation to make Fe 2+ Concentration is 2mmol / L, H 2 o 2 The concentration is 4.5mmol / L, and the reaction time is 400 minutes. The Fenton oxidation effluent was reacted with the amino-modified magnetic ultra-high cross-linked composite functional resin accounting for 3% of the water volume, and after 500 minutes of reaction, solid-liquid separation was carried out. The quality of the effluent after separation is shown in Table 3. Regenerate with a desorption solution containing 18wt.% sodium hydroxide and 50wt.% methanol, and the regeneration time is 60 minutes. Regenerated resin continues to react as fresh resin. The waste water of this plant complies with the reuse standard of reclaimed water, and it is listed in Table 3 with refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com