Method for preparing anisotropic composite particles

A composite particle and anisotropic technology, which is applied in the field of synthesis of anisotropic asymmetric composite particles, can solve problems such as poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

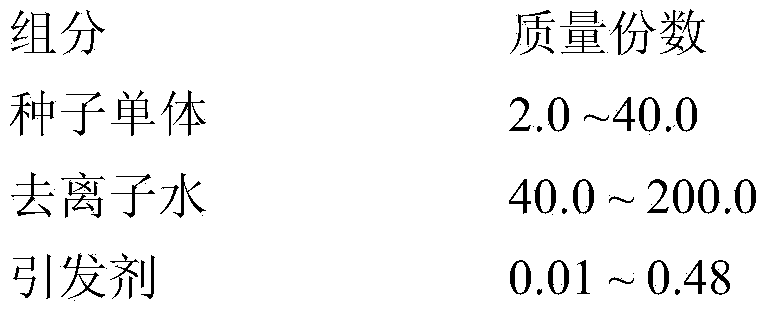

[0026] (a), Preparation of seed emulsion:

[0027]

[0028] Add 10.0g of seed monomer and 90.0g of deionized water into the reactor, start stirring, pass nitrogen gas into the whole process, reflux and condense, add 0.1g of initiator after the system reaches 75°C, polymerize for 5 hours, and preliminarily prepare the seeds Lotion;

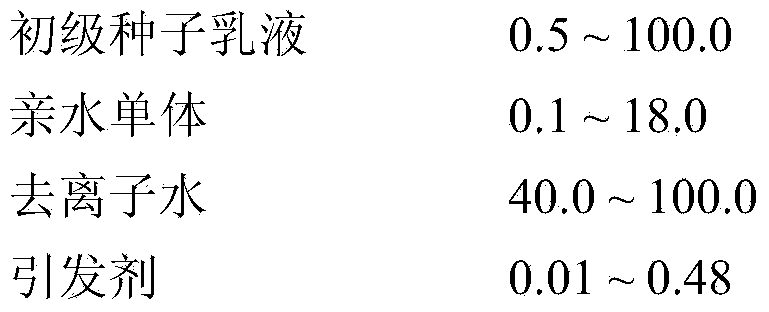

[0029]

[0030] Take 52.5g of the prepared primary seed emulsion (containing about 5g of seeds), add 0.5g of hydrophilic monomer acrylamide and 90.0g of deionized water, add an initiator after the system reaches 80°C, and polymerize for 10 hours to obtain the seed emulsion .

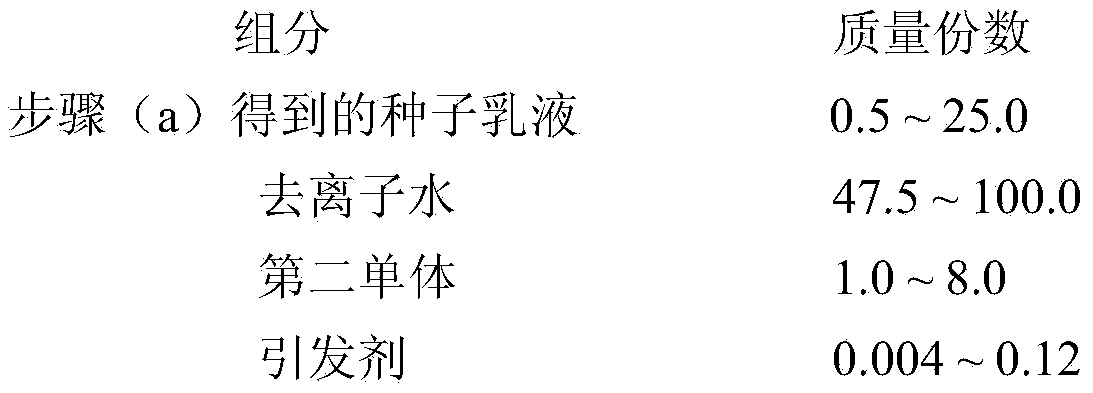

[0031] (b), Preparation of anisotropic particles:

[0032]

[0033] Add 80.0g of deionized water to the seed emulsion (27.0g) obtained in step (a), after ultrasonic dispersion, start stirring, pass nitrogen gas through the whole process, and perform reflux condensation, add 3.0g of the second monomer and 0.018g of initiator Potassium persulfate is used as an agent...

Embodiment example 2-5

[0035] In the implementation cases 2-5, the amount of the hydrophilic monomer was changed to 1.0 g, 2.0 g, and 3.0 g respectively, and the rest of the steps were the same as in the implementation case 1.

Embodiment example 6-7

[0037] In the implementation cases 6-7, the hydrophilic monomers were changed to acrylic acid and vinyl acetate respectively, and the amount of the hydrophilic monomers was 1.0 g, and the rest of the steps were the same as in the implementation case 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com