Safe blocking remover polymer injection well of oil field

A technology for injecting polymer wells and removing plugging agents, which is applied in the directions of drilling compositions, chemical instruments and methods, and can solve problems such as hidden dangers, poor effects, and unsafe oil fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

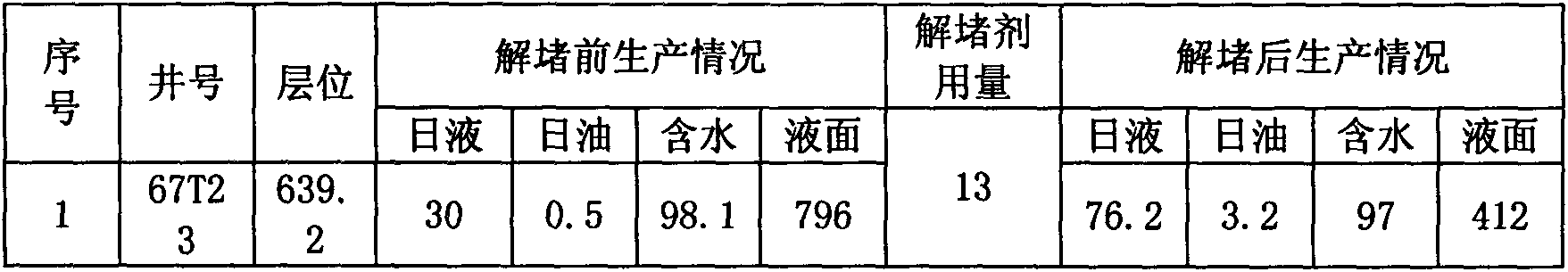

Examples

Embodiment 1

[0005] The oilfield polymer injection well safety plugging remover is characterized in that it consists of the following components in volume percentage:

[0006] A double base curing cracking agent 1.0%------5.0%

[0007] B dispersant 3.0%------6.0%

[0008] C Self-generated gas foaming energy-enhancing diffuser 1.0%------5.0%

[0009] Wherein the double base curing cracking agent is compounded by H chemical substances and complexes, said H chemical substances refer to chemical substances that can generate oxygen free radicals after decomposition, and said H chemical substances Contains Calcium Peroxide, Potassium Persulfate, Complexes Contains Diphenylthiourea, EDTA. The double-base curing cracking agent is a synthetic product of at least one of the above-mentioned H chemicals and at least one of the above-mentioned complexes. The dispersant is one of triethylhexyl phosphoric acid, methyl amyl alcohol, and polyacrylamide, and the self-generated gas foaming and energy-enha...

Embodiment 2

[0011] Oil field polymer injection well safety plugging remover, composed of 1.0% double-base solidification cracking agent, 3.0% dispersant, 1.0% self-generated gas foaming energy-enhancing diffusing agent and other components are water:

[0012] Wherein the double-base curing cracking agent is compounded by H chemical substances and complexes, the H chemical substances are calcium peroxide, and the complexes are diphenylthiourea. The double-base curing cracking agent is a synthetic product of calcium peroxide and diphenylthiourea. The dispersant is triethylhexyl phosphoric acid, and the self-generated gas foaming energy-enhancing diffusing agent is compounded with an aqueous solution of sodium nitrite and ammonium chloride. The aqueous solution of sodium nitrite and ammonium chloride used in the self-generating gas foaming energy-enhancing diffusing agent is configured at a concentration of 1% by mass. The medicaments and water of the above-mentioned components are miscible...

Embodiment 3

[0014] Oilfield polymer injection well safety plugging remover, composed of 3.0% double-base solidification cracking agent, 4.5% dispersant, 0.2% earth acid, 2.25% corrosion inhibitor, 2.0% clay anti-swelling agent, and other components are water:

[0015] Wherein the double base curing cracking agent is compounded by H chemical substances and complexes, the H chemical substances are potassium persulfate, and the complexes are ethylenediaminetetraacetic acid. The double-base curing cracking agent is a synthetic product of potassium persulfate and ethylenediaminetetraacetic acid. The dispersant is methyl amyl alcohol, and the self-generated gas foaming and energy-enhancing diffusing agent is compounded with an aqueous solution of sodium nitrite and ammonium chloride. The aqueous solution of sodium nitrite and ammonium chloride used in the self-generating gas foaming energy-enhancing diffusing agent is configured at a concentration of 1% by mass. The medicaments and water of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com