Method for preparing aromatic hydrocarbon by coal tar oil

A technology of coal tar and aromatics, applied in the field of producing aromatics from coal tar, to achieve high yield and alleviate the effect of insufficient supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

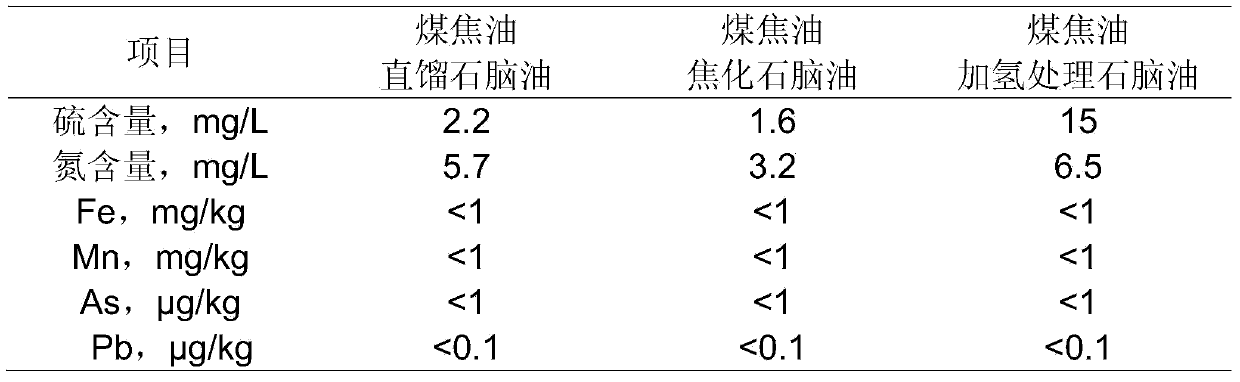

[0037]The medium and low temperature coal tar is sent to the pretreatment unit to remove mechanical impurities and water, and then enters the atmospheric and vacuum fractionation tower to obtain the straight-run naphtha fraction. The naphtha fraction is pre-fractionated, and the 60-145°C fraction is selected. See Table 1; the remaining fractions are coked, cracked or hydrotreated to obtain naphtha fractions, and the naphtha fractions are pre-fractionated to obtain raw material components for the production of aromatics. Then pre-hydrogenate the selected straight-run naphtha fraction and raw material components, reform the pre-hydrogenated product that meets the reforming raw material conditions, and then separate the reformed product aromatics mixture through aromatics extraction to obtain benzene , toluene, C 8 and C 8+ The components are further isomerized to produce benzene or benzene and p-xylene.

Embodiment 2

[0039] The medium and low temperature coal tar is sent to the pretreatment unit to remove mechanical impurities and water, then enters delayed coking, and then undergoes hydrotreating, and the treated oil enters atmospheric and vacuum fractionation to obtain coking naphtha fractions. The fractions were pre-fractionated, and the fractions at 60-145°C were selected. The properties are shown in Table 1. Then pre-hydrogenation is carried out, and the pre-hydrogenation product that meets the conditions of the reforming raw material is reformed, and then the aromatic hydrocarbon mixture of the reformed product is separated through aromatic hydrocarbon extraction to obtain benzene, toluene, C 8 and C 8+ The components are further isomerized to produce benzene or benzene and p-xylene.

Embodiment 3

[0041] The medium and low temperature coal tar is sent to the pretreatment unit to remove mechanical impurities and water, then enters the hydrogenation unit, and then enters the atmospheric and vacuum distillation unit to obtain the hydrocracked naphtha fraction, which is pre-fractionated, and 60 ~145°C distillate section, the properties are shown in Table 1. Then pre-hydrogenation is carried out, and the pre-hydrogenation product that meets the conditions of the reforming raw material is reformed, and then the aromatic hydrocarbon mixture of the reformed product is separated through aromatic hydrocarbon extraction to obtain benzene, toluene, C 8 and C 8+ The components are further isomerized to produce benzene or benzene and p-xylene.

[0042] Attached Table 1: 60~145℃ Distillate Section Naphtha Properties

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com