Method for preparing briquettes fuel from deoiled kitchen waste

A technology of kitchen waste and briquette fuel, which is applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of huge investment and complicated process, and achieve recycling, avoid solid phase landfill, and high energy utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

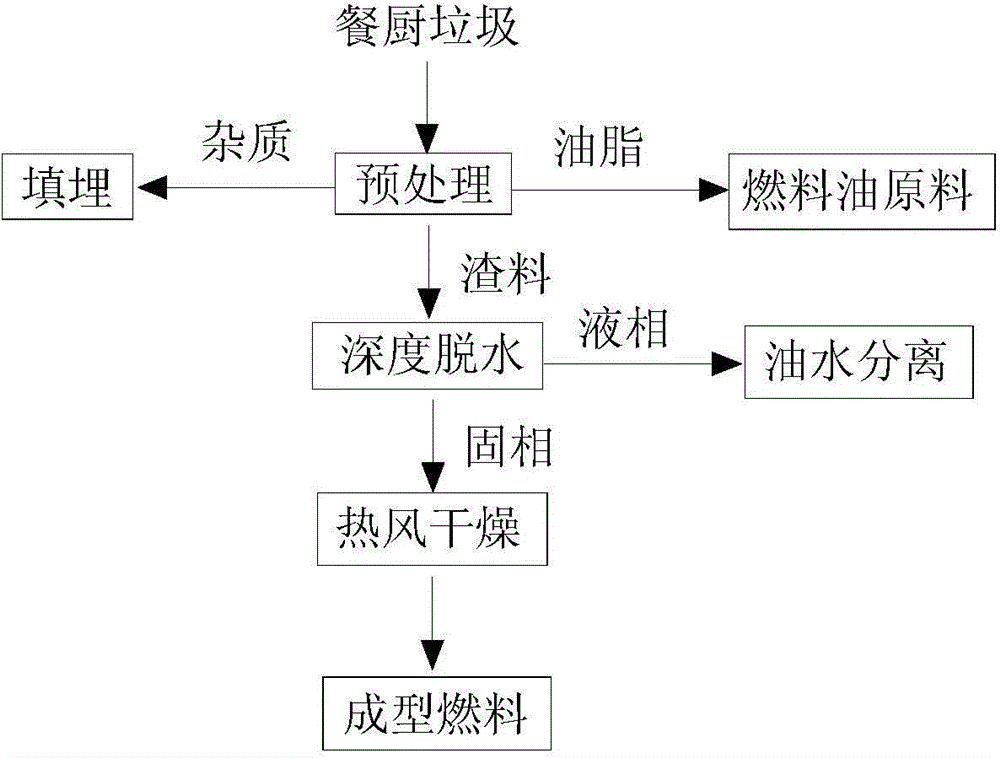

[0037] After sending the special sealed container for food waste to the disposal point, refer to figure 1 , do the following:

[0038] 1) Preprocessing

[0039] Food waste is weighed and measured before sorting. Sorting uses twisted cages to remove plastic bags (cloth) and large debris for subsequent crushing. The rest of the sorted food waste is crushed with a reamer and screened by a vibrating screen (Guosheng DZSF520 type) to remove impurities, and the food waste with a particle size of 10mm or less is obtained, and the removed impurities are landfilled.

[0040] After removing impurities, the food waste with a particle size of 10mm or less is heated to 80°C, kept warm for 20 minutes, and then enters the three-phase separation equipment Fuller LW-350 horizontal spiral sedimentation centrifuge for deoiling, separating oil, water, Slag. The water separated by deoiling enters the wastewater treatment system, the grease is used as fuel oil raw material, and the residue after...

Embodiment 2

[0049] After sending the special sealed container for food waste to the disposal point, refer to figure 1 , do the following:

[0050] 1) Preprocessing

[0051] Food waste is weighed and measured before sorting. Sorting uses twisted cages to remove plastic bags (cloth) and large debris for subsequent crushing. The rest of the sorted food waste is crushed with a reamer and screened by a vibrating screen (Guosheng DZSF520 type) to remove impurities. The food waste with a particle size of 10mm or less is obtained, and the removed impurities are buried.

[0052] After cleaning, the food waste with a particle size of 10mm or less is heated to 80°C, and the briquette fuel obtained in Example 1 is burned with a biomass burner (Zinhai H60 type), and the combustion flue gas is used for heating.

[0053] After 20 minutes of heat preservation, it enters the three-phase separation equipment Fuller LW-350 horizontal spiral sedimentation centrifuge for deoiling, and separates oil, water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com