Method for preparing ZnFe2O4 by cathode electrodeposition

A cathodic electrodeposition, znfe2o4 technology, applied in the field of inorganic optoelectronic materials preparation process, to achieve the effect of environmental friendliness, low cost and fast deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) The working electrode, that is, the activation of ITO conductive glass: wash the ITO conductive glass with acetone for 3 times, then clean the conductive glass with deionized water in an ultrasonic cleaner for 30 minutes, and then place the conductive glass in dilute nitric acid solution for 30 seconds. , and finally washed with deionized water and set aside;

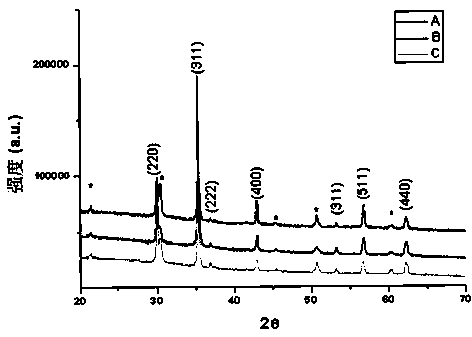

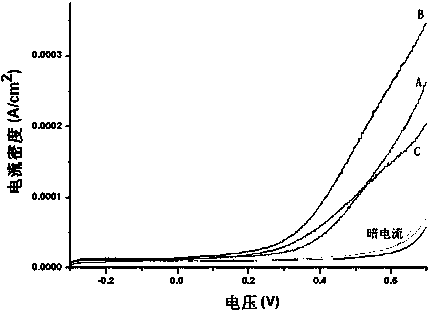

[0016] 2) ZnFe 2 o 4 Preparation of thin film electrodes: 0.0087mol of Fe(NO 3 ) 2 9H 2 Dissolve O in 20 mL of distilled water, stir for 5 min, add 0.0100 mol of triethanolamine, stir for 1 h, and make it react with Fe 3+ After fully complexing, add 0.2000mol of NaOH, stir until the solution is clear, then add 0.0030mol of Zn(NO 3 ) 2 ·6H 2 O, continue to stir for 1h, add deionized water to obtain a clarified electrolyte solution with a volume of 100mL; use ITO conductive glass as the working electrode, platinum sheet electrode as the counter electrode, and silver-silver chloride electrode as the refere...

Embodiment 2

[0020] 1) The working electrode, that is, the activation of ITO conductive glass: wash the ITO conductive glass with acetone for 5 times, then clean the conductive glass with deionized water in an ultrasonic cleaner for 60 minutes, and then place the conductive glass in a dilute nitric acid solution to activate it for 60 seconds , and finally washed with deionized water and set aside;

[0021] 2) ZnFe 2 o 4 Preparation of thin film electrodes: 0.0087mol of Fe(NO 3 ) 2 9H 2 Dissolve O in 20 mL of distilled water, stir for 10 min, add 0.0100 mol of triethanolamine, stir for 2 h, and make it react with Fe 3+ After fully complexing, add 0.2000mol of NaOH, stir until the solution is clear, then add 0.0030mol of Zn(NO 3 ) 2 ·6H 2 O, continue to stir for 2h, add deionized water to obtain a clarified electrolyte solution with a volume of 100mL; use ITO conductive glass as the working electrode, the platinum sheet electrode as the counter electrode, and the silver-silver chlorid...

Embodiment 3

[0025] 1) The working electrode, that is, the activation of ITO conductive glass: wash the ITO conductive glass with acetone for 4 times, then clean the conductive glass with deionized water in an ultrasonic cleaner for 40 minutes, and then place the conductive glass in dilute nitric acid solution to activate it for 40 seconds , and finally washed with deionized water and set aside;

[0026] 2) ZnFe 2 o 4 Preparation of thin film electrodes: 0.0087mol of Fe(NO 3 ) 2 9H 2 O was dissolved in 20mL of distilled water, stirred for 8min, added 0.0100mol of triethanolamine, stirred for 1.5h, and Fe 3+ After fully complexing, add 0.2000mol of NaOH, stir until the solution is clear, then add 0.0030mol of Zn(NO 3 ) 2 ·6H 2 O, continue to stir for 1.5h, add deionized water to obtain a clarified electrolyte solution with a volume of 100mL; use ITO conductive glass as the working electrode, the platinum sheet electrode as the counter electrode, and the silver-silver chloride electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com