Cascading refrigerating system and method based on forward and reverse cycle coupling

A refrigeration system, cascading technology, applied in refrigerators, refrigeration and liquefaction, and compressors with cascading work, etc., can solve problems such as high consumption, difficulty in meeting requirements for single-stage ammonia water, and complex systems, etc., to achieve Reduce the effect of irreversible loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

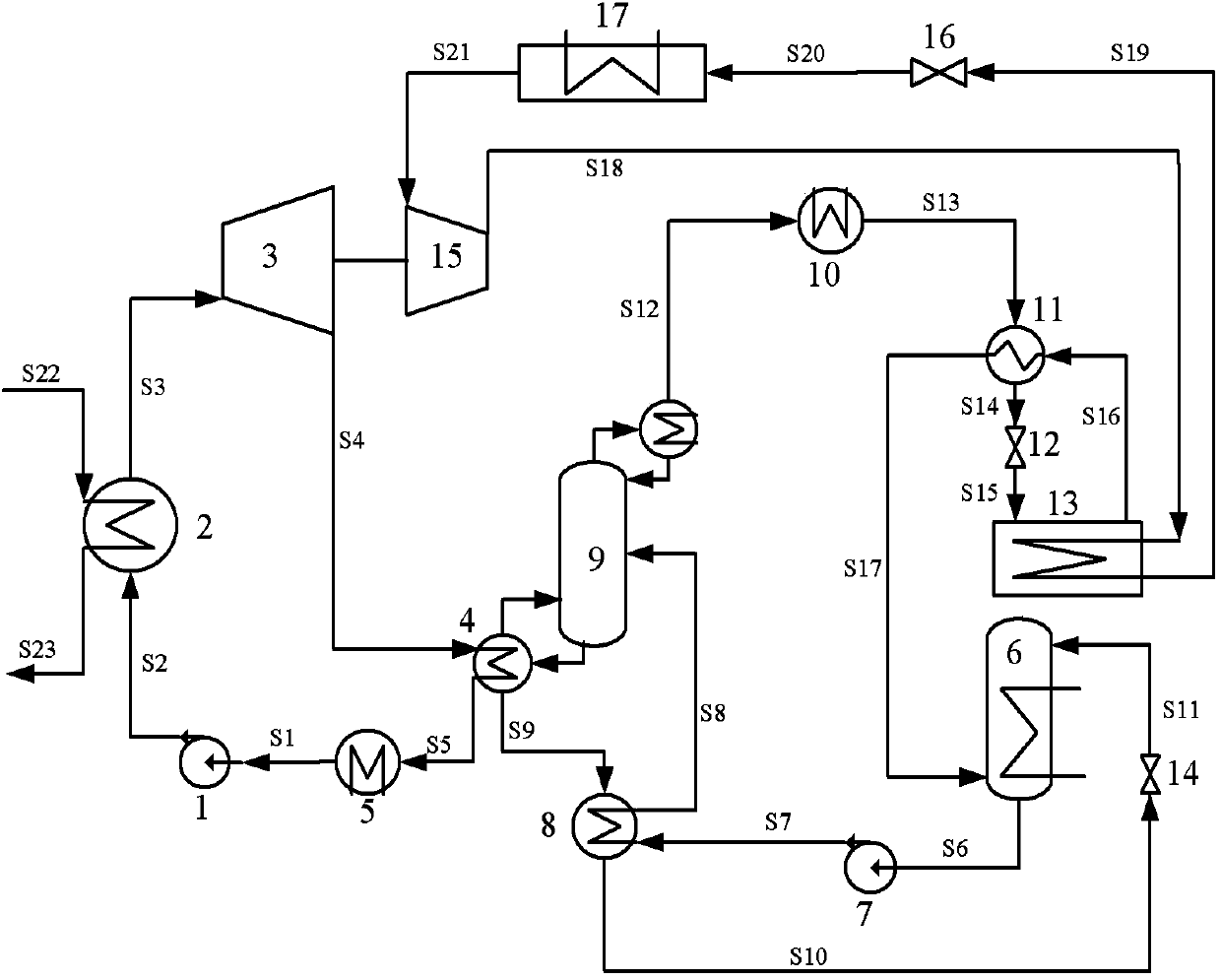

[0023] Such as figure 1 as shown, figure 1 It is a schematic diagram of an embodiment of a cascade refrigeration system based on forward and reverse cycle coupling provided by the present invention. Among them, S1 to S21 represent circulating working fluids. S22 and S23 represent heat source media. The system includes a power sub-cycle, an absorption refrigeration sub-cycle and a compression refrigeration sub-cycle. The work done drives the compression refrigeration sub-cycle to refrigerate. The absorption refrigeration sub-cycle and the compression refrigeration sub-cycle constitute a cascade refrigeration system. The absorption refrigeration sub-cycle works in the high temperature area, and the compression refrigerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com