Online detection method for content of HMX in HMX production process

A technology of Oktokin and production technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of quality information distortion, long test cycle, lagging analysis results, etc., achieve accurate online detection, high accuracy, and overcome time constraints Lag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

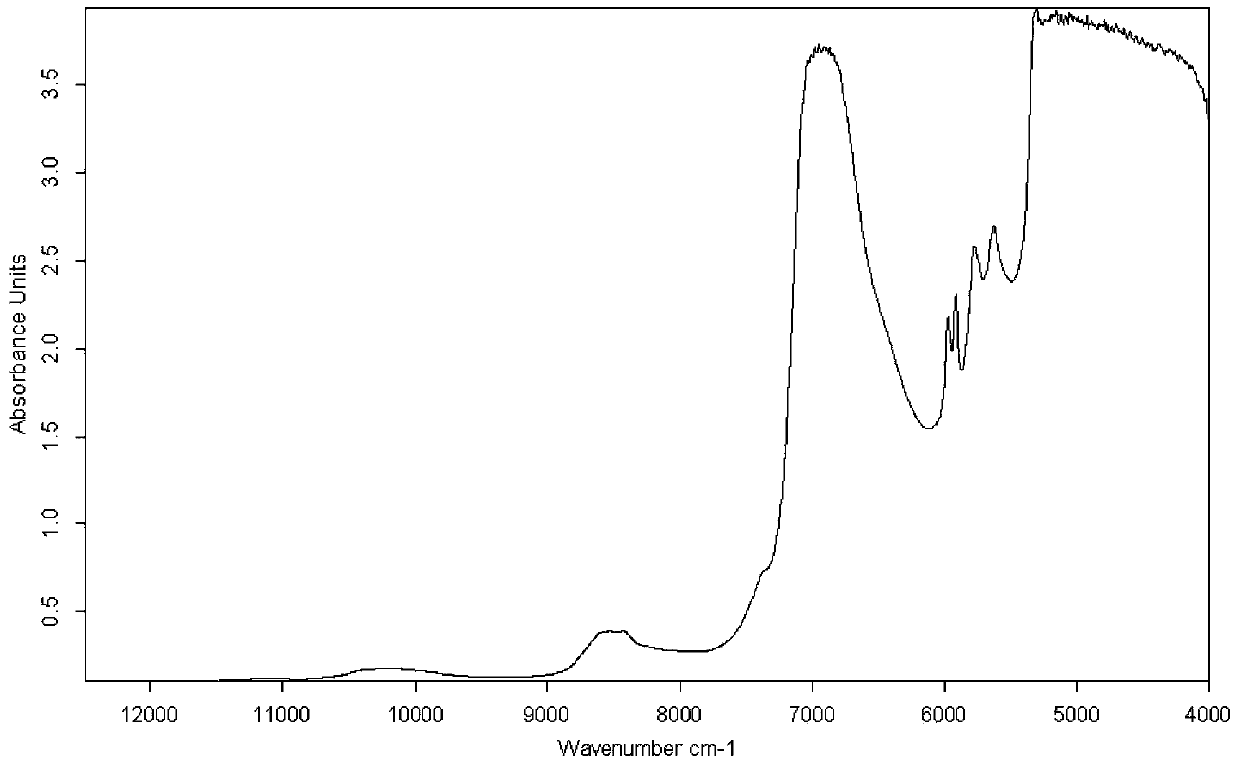

[0095] This embodiment provides an online detection method for Octogen content in the Octogen production process, the method comprising the following steps:

[0096] Step 1, determine the Octogen content of the sample:

[0097]Collect the samples in the mixing process of synthesizing Octogen with a sampling time interval of 30 seconds and collect 18 samples; collect the samples in the nitration process of synthesizing Octogen with a sampling interval of 40 seconds and collect 18 samples; The sample sampling time interval during the pyrolysis process of collecting synthetic Octogen was 30 seconds, and 18 samples were collected; each sample was pretreated, and the specific pretreatment method was: from the reaction system (mixing process, nitrification process and The reaction system of the pyrolysis process) sampled 1 ml, added to a 250 ml beaker containing 20 g of ice-water mixture, and added 100 ml of ethanol; the pH value of the sample was adjusted to 2-8 by adding ammonia w...

Embodiment 2

[0126] This embodiment provides an online detection method for Octogen content in the Octogen production process, the method comprising the following steps:

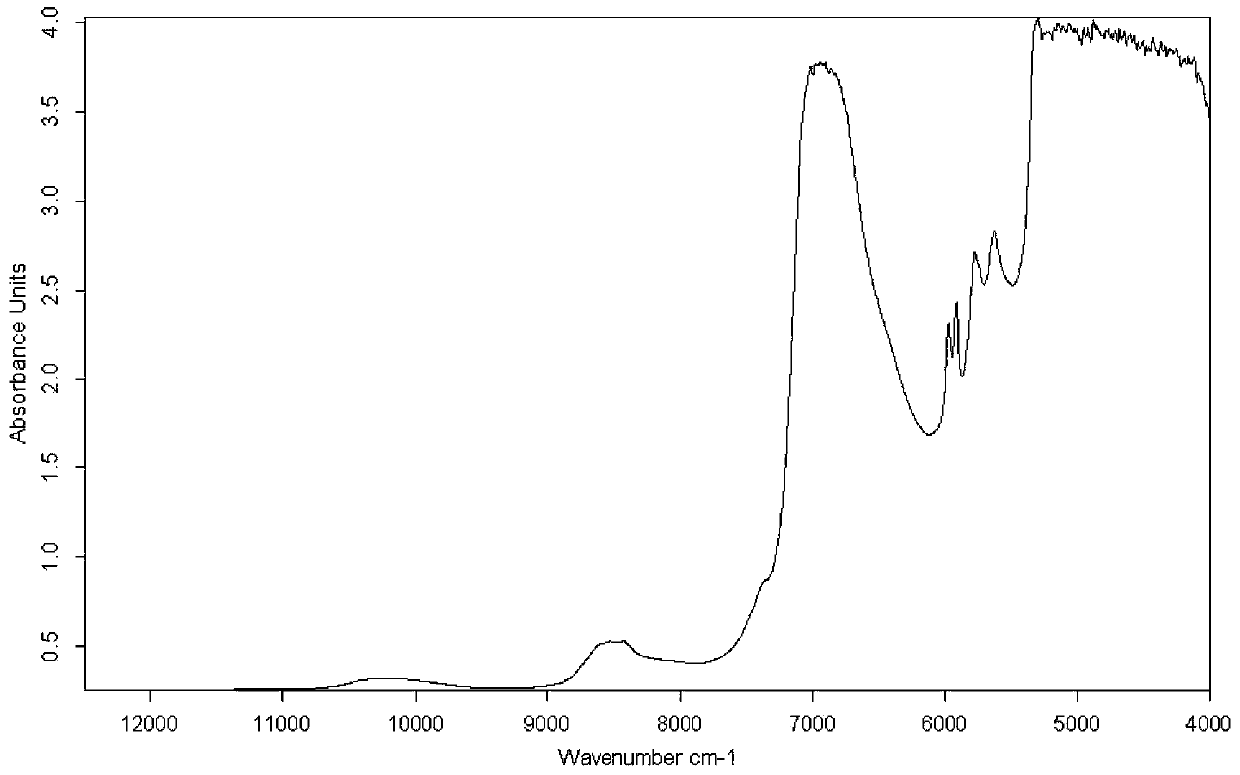

[0127]The method of step 1, step 2 and step 3 in the present embodiment is the same as the method of step 1, step 2 and step 3 in embodiment 1, obtains 54 near-infrared spectra of the sample, and records them as original spectra, and obtains the most best modeling interval.

[0128] Step 4, preprocessing of the original spectrum:

[0129] The standard normal variable transformation is performed on the collected original spectrum to obtain the near-infrared spectrum after the standard normal variable transformation. The standard normal variable transformation is used to eliminate the influence of solid particle size, surface scattering and optical path changes on the near-infrared diffuse reflection spectrum The standard normal variable transformation can be replaced by multivariate scattering correction to obtain the ne...

Embodiment 3

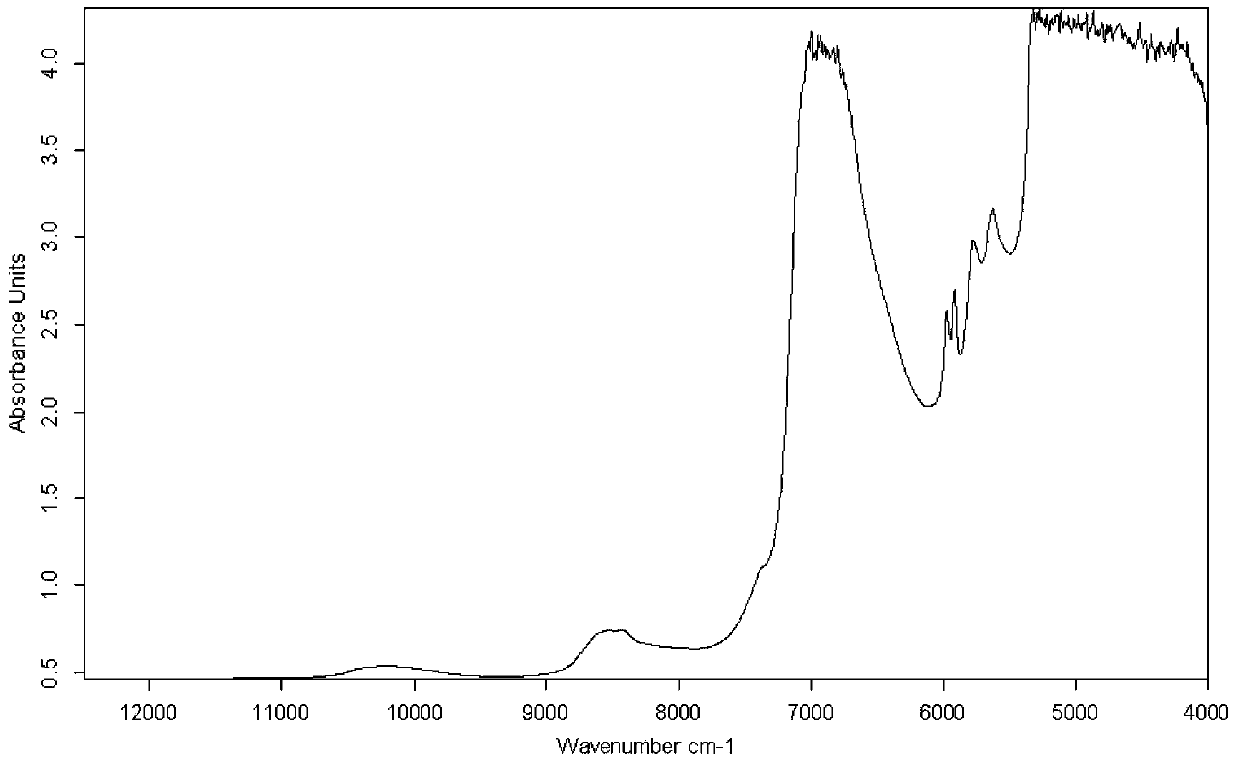

[0138] This embodiment provides an online detection method for Octogen content in the Octogen production process, the method comprising the following steps:

[0139] The method of step 1, step 2 and step 3 in the present embodiment is the same as the method of step 1, step 2 and step 3 in embodiment 1, obtains 54 near-infrared spectra of the sample, and records them as original spectra, and obtains the most best modeling interval.

[0140] Step 4, preprocessing of the original spectrum:

[0141] Carry out any combination of smoothing, differential processing, standard normal variable transformation and multivariate scattering correction to the original spectrum, and the specific smoothing, differential processing, standard normal variable transformation and multivariate scattering correction processing methods are the same as in Example 1 and implementation The processing method in Example 2 is the same, and the near-infrared spectrum after any combination of smoothing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com