Double-heat-source semi-automatic cultivation facilitating system for large cherries

A technology that promotes cultivation and dual heat sources is applied in the field of semi-automatic cultivation systems for large cherry with dual heat sources, which can solve the problems of decreased yield and quality, impact on economic benefits, labor intensity and human operation errors, etc. The effect of stable and improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

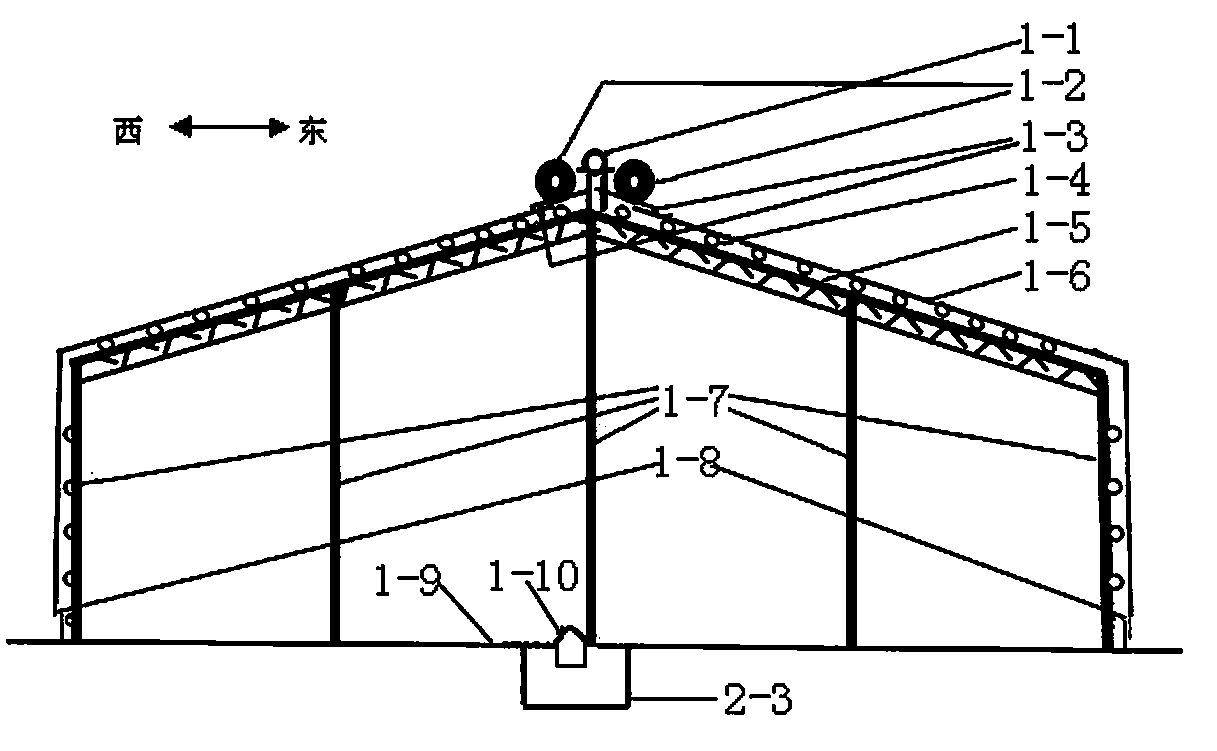

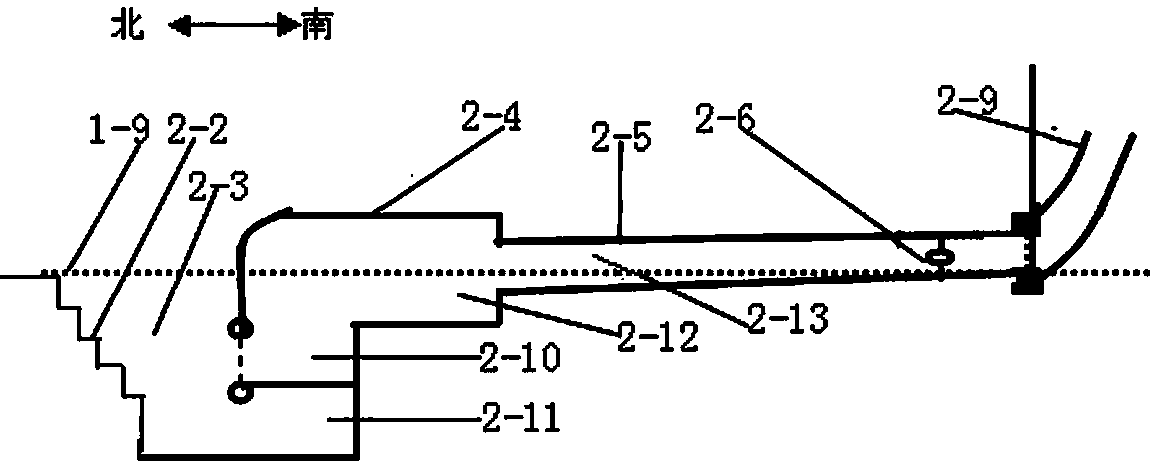

[0025] Such as figure 1As shown, the shed body of the greenhouse adopts a steel frame structure and is built along the north-south direction. Its length, width, shoulder height, and top height are 100m, 20m, 4.5m, and 7.5m respectively, and 1 / 2 of the width is 10m. The slope between shoulder height and crown height is 3 / 10. Its steel frame structure is constructed by several steel pipe columns 1-7 of different lengths, several steel pipe beams 1-4 and steel pipe supports 1-5; with the longest steel pipe column 1-7 as the center, the east and west sides each There are two rows of steel pipe columns 1-7; wherein, the tops of all the longest steel pipe columns 1-7 form a north-south ridge of the shed. The steel frame structure is covered with plastic film 1-6, and the plastic film 1-6 has two top ventilation adjustment seams 1-3 and bottom ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com