Compound fresh-keeping tartary buckwheat noodles and preparation method thereof

A technology of tartary buckwheat flour and tartary buckwheat, which is applied in the field of noodle products, can solve the problems of normal noodle ductility and palatability, time-consuming production process, and increasing the sugar content of dried noodles, so as to increase the natural vegetable protein content and dilute the bean flavor Taste, the effect of improving glucose tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

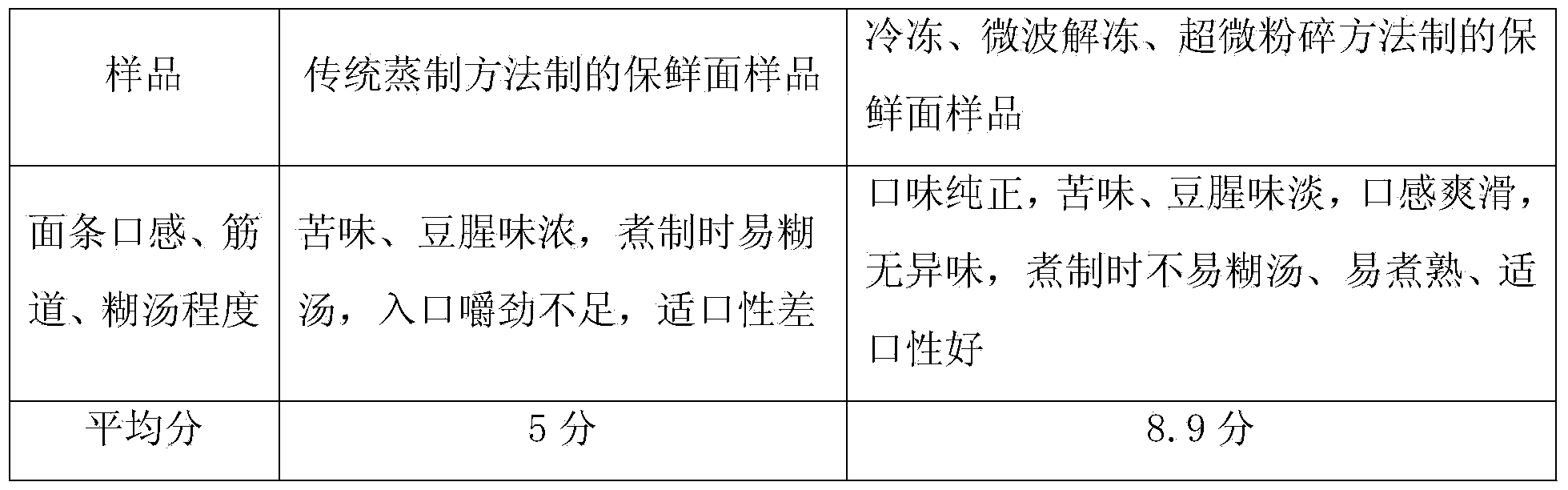

Examples

Embodiment 1

[0031] A compound tartary buckwheat fresh-keeping noodle is prepared from compound flour and water, and the weight ratio of the compound flour to water is 100:32;

[0032] The 100kg compound tartary buckwheat fresh-keeping noodles are composed of the following raw materials in weight percentage: 72% of tartary buckwheat flour, 12% of soybean flour, 8% of high-gluten wheat flour, 6% of gluten powder, and 2% of refined salt;

[0033] The tartary buckwheat flour is selected from fresh tartary buckwheat traditional milling of the year, with crude protein ≥ 12.5%, ash content ≥ 1.5%, water content ≤ 14%, and a fineness that can pass through a 70-mesh sieve.

[0034] The soybean flour is selected from fresh soybeans with full particles, light yellow skin color, no mildew spots, and no moths. After cleaning, dry them at 105°C (air drying is also acceptable), and use a high-speed pulverizer to crush them until they can pass through a 70-mesh net. screen.

[0035] The wheat flour is s...

Embodiment 2

[0050] A compound tartary buckwheat fresh-keeping noodle is prepared from compound flour and water, and the weight ratio of the compound flour to water is 100:32;

[0051] The 100 kg compound tartary buckwheat fresh-keeping noodles are composed of the following raw materials in weight percentage: 68 kg of tartary buckwheat flour, 13 kg of soybean flour, 10 kg of high-gluten wheat flour, 7 kg of gluten powder, and 2 kg of refined salt.

[0052] The tartary buckwheat flour is selected from fresh tartary buckwheat traditional milling of the year, with crude protein ≥ 12.5%, ash content ≥ 1.5%, water content ≤ 14%, and a fineness that can pass through a 70-mesh sieve.

[0053] The soybean flour is selected from fresh soybeans with full particles, light yellow skin color, no mildew spots, and no moths. After cleaning, dry them at 105°C (air drying is also acceptable), and use a high-speed pulverizer to crush them until they can pass through a 70-mesh net. screen.

[0054] The whea...

Embodiment 3

[0069] A compound tartary buckwheat fresh-keeping noodle is prepared from compound flour and water, and the weight ratio of the compound flour to water is 100:35;

[0070] The 100kg compound tartary buckwheat fresh-keeping noodles consist of the following raw materials in weight percentage: 80kg tartary buckwheat flour, 6kg soybean flour, 8kg high-gluten wheat flour, 5kg gluten powder, and 1kg refined salt.

[0071] The tartary buckwheat flour is selected from fresh tartary buckwheat traditional milling of the year, with crude protein ≥ 12.5%, ash content ≥ 1.5%, water content ≤ 14%, and a fineness that can pass through a 70-mesh sieve.

[0072] The soybean flour is selected from fresh soybeans with full particles, light yellow skin color, no mildew spots, and no moths. After cleaning, dry them at 105°C (air drying is also acceptable), and use a high-speed pulverizer to crush them until they can pass through a 70-mesh net. screen.

[0073] The wheat flour is selected from dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com