A kind of molybdenum oxide nano photothermal conversion material and preparation method thereof

A nano-light and heat conversion technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of easy deformation of precious metals, high cost of precious metals restricting wide application, unstable photothermal performance, etc., to achieve strong The effect of near-infrared light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

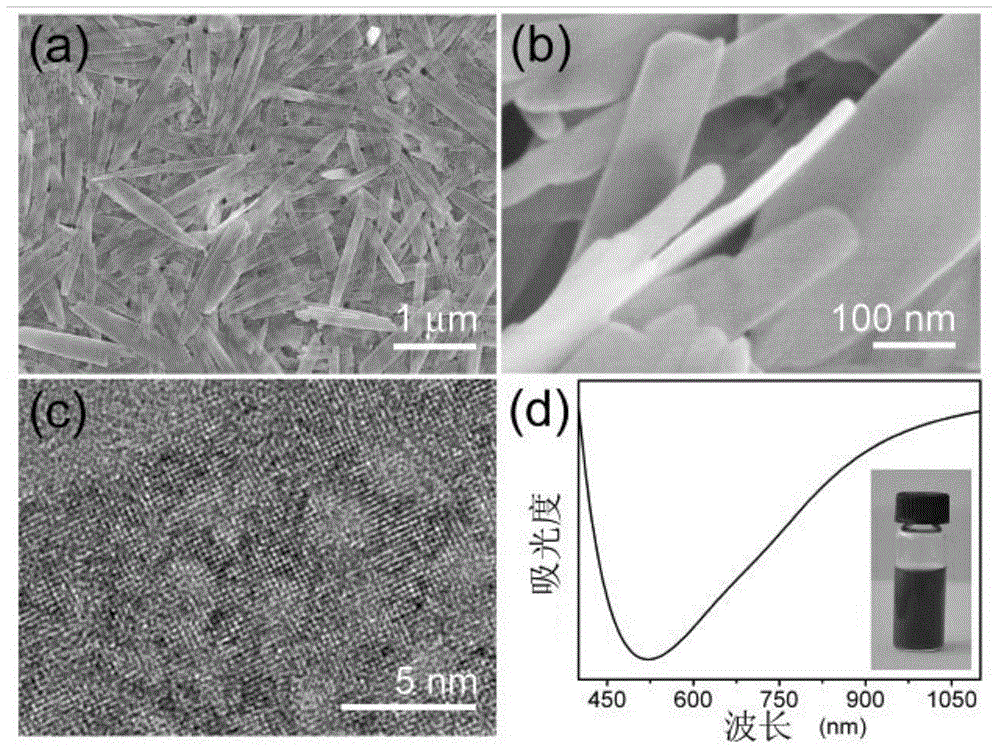

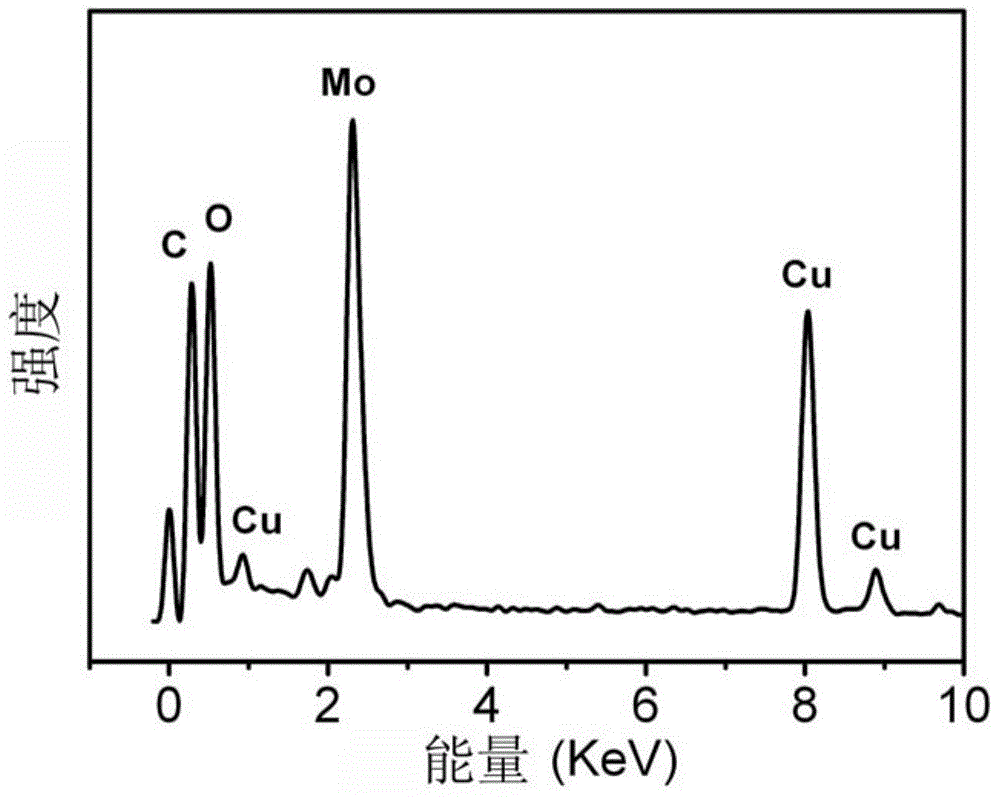

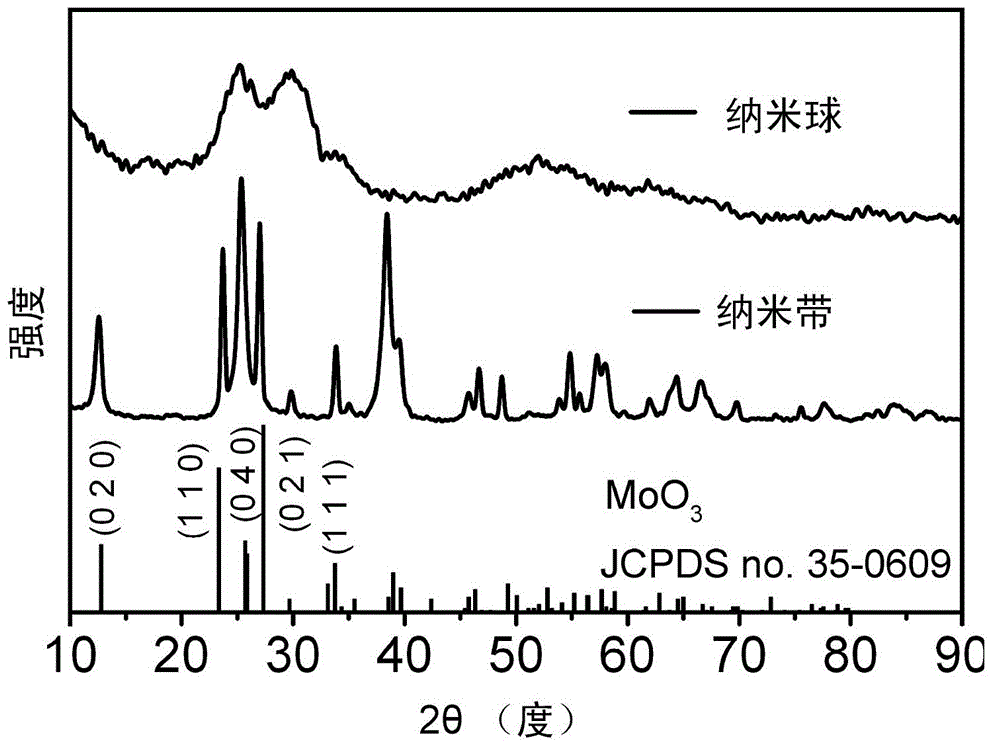

Embodiment 1

[0037] 60mL of H 2 o 2 Add dropwise to 4.78g molybdenum powder, and keep stirring to form a yellow solution, and then dilute the solution to 100mL to obtain a molybdenum precursor solution. Add 10g of PEG to 20mL of molybdenum precursor solution, stir to form a transparent yellow solution, transfer it to a polytetrafluoroethylene reactor, seal it, and then raise the temperature to 150°C in a blast oven for 12 hours. After the reaction, the product was collected by centrifugation and washed with deionized water. The prepared MoO 3-x Nanobelts such as figure 1 a,b,c shown. MoO 3-x Nanoribbons can be well dispersed in water, appear blue and have gradually enhanced near-infrared light absorption properties, such as figure 1 d. The energy spectrum under the transmission electron microscope proves that it contains molybdenum and oxygen elements, such as figure 2 . The prepared MoO 3-x XRD patterns of nanobelts and standard MoO 3 (JCPDS, no35-0609) corresponding to the ...

Embodiment 2

[0039] 60mL of H 2 o 2 Add dropwise to 4.78g molybdenum powder, and keep stirring to form a yellow solution, and then dilute the solution to 100mL to obtain a molybdenum precursor solution. Add 10g of PEG to 20mL of molybdenum precursor solution, stir to form a transparent yellow solution, transfer it to a polytetrafluoroethylene reactor, seal it, and then raise the temperature to 90°C in a blast oven for 12h. After the reaction, the product was collected by centrifugation and washed with deionized water. The prepared MoO 3-x Nanospheres such as Image 6a,b,c shown. MoO 3-x Nanospheres can be well dispersed in water, appear blue and have strong near-infrared light absorption, with a peak at 750nm, such as Image 6 d. At a power of 2W / cm 2 Excited by an 808nm laser, the MoO 3-x Nanospheres can absorb 808nm laser light and generate heat effectively, raising the ambient temperature by 35°C within 5 minutes, such as Figure 7 .If MoO 3-x Nanospheres were incubated with ...

Embodiment 3

[0041] 60 mL of H 2 o 2 Add dropwise to 4.78g molybdenum powder, and keep stirring to form a yellow solution, and then dilute the solution to 100mL to obtain a molybdenum precursor solution. Dissolve 5g of PVP in 10mL of water, then add it to 10mL of molybdenum precursor solution, stir to form a transparent yellow solution, transfer it to a polytetrafluoroethylene reactor, seal it, and then heat it up to 120°C in a blast oven for 12h. After the reaction, the product was collected by centrifugation and washed with deionized water. The prepared MoO 3-x Nanorods such as Figure 8 shown. MoO 3-x Nanorods have strong near-infrared light absorption, and their absorption peak is at 700nm, such as Figure 9 shown. If MoO 3-x Nanospheres were incubated with cancer cells, and after 10 minutes of 808nm laser irradiation, the local temperature increased rapidly, and MoO 3-x Nanospheres can effectively kill cancer cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com