Organic biological multi-element plant nutrient polymer and production method thereof

An organic biology and multi-element technology, applied in the field of agriculture, can solve the problems of poor utilization of solid waste and pollution of the environment, and achieve the effects of facilitating manual handling, high single fruit weight, and reduced bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

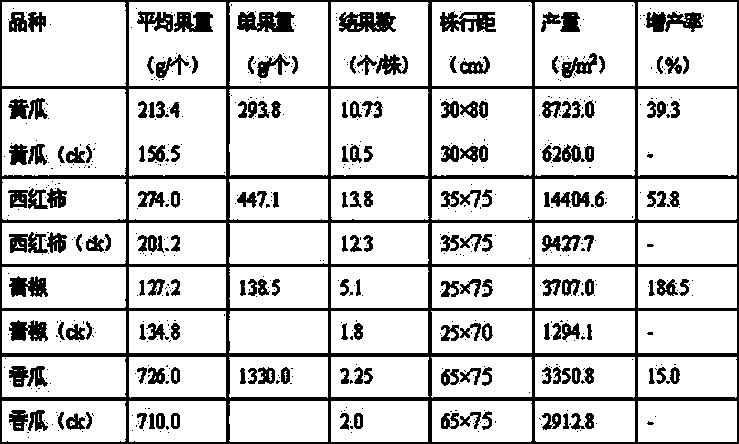

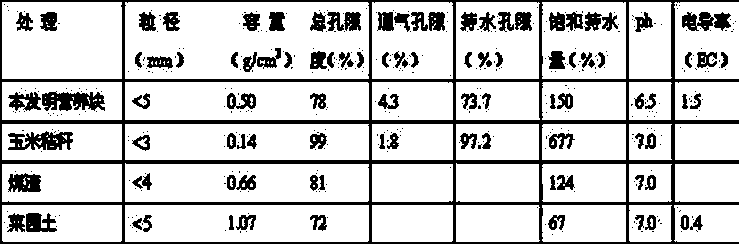

Examples

Embodiment 1

[0037] Raw materials and methods comprising the following ratios in parts by weight:

[0038] Agricultural solid waste: 50 parts of corn stalks,

[0039] 10 parts of pig manure;

[0040] Microbial agent: a mixture of yeast and lactic acid bacteria, the ratio is 4:6; 0.05 parts;

[0041] 5 parts of cinder;

[0042] Biological power plant ash: 5 parts of waste pollutant ash produced by straw power plants;

[0043] 2 parts of reprocessed bentonite produced in industrial coal mines;

[0044] Azotobacter: Klebsiella and A. chroococcum, the ratio is 1:1, 0.1 parts;

[0045] Water retaining agent: 0.5 parts of polyacrylamide PAM soil water retaining agent;

[0046] method:

[0047] Take the raw materials in the formula, the corn stalks used are rubbed, crushed and chopped into 3-5mm long, sprinkled with water, so that the relative water content is 50%-65%, after the above corn stalks are mixed with pig manure, inoculated with microbial agents , pile up and ferment under normal...

Embodiment 2

[0049] Raw materials and methods comprising the following ratios in parts by weight:

[0050] Agricultural solid waste: rice and soybean straw mixed in any proportion, 65 parts;

[0051] Mix chicken manure and cow manure in any proportion, 20 parts;

[0052] Microbial agent: a mixture of yeast and lactic acid bacteria, the ratio is 4:6; 0.08 parts;

[0053] 7.5 parts of cinder;

[0054] Biological power plant ash: 7.5 parts of waste pollutant ash produced by straw power plants;

[0055] 3 parts of reprocessed bentonite produced in industrial coal mines;

[0056] Azotobacter: Klebsiella and A. chroococcum, the ratio is 1:1, 0.15 parts;

[0057] Water retaining agent: 1.25 parts of polyacrylamide PAM soil water retaining agent;

[0058] method:

[0059] Take the raw materials in the formula, the rice and soybean straw used are rubbed, crushed and chopped into 3-5mm long, sprinkled with water to make the relative water content 50%-65%, and the above rice and soybean straw a...

Embodiment 3

[0061] Raw materials and methods comprising the following ratios in parts by weight:

[0062] Agricultural solid waste: corn, wheat, sorghum straw mixed in any proportion, 80 parts;

[0063] Mix pig manure, cow manure and sheep manure in any proportion, 30 parts;

[0064]Microbial agent: a mixture of yeast and lactic acid bacteria, the ratio is 4:6; 0.1 part;

[0065] 10 parts of cinder;

[0066] Biological power plant ash: 10 parts of waste pollutant ash produced by straw power plants;

[0067] 4 parts of reprocessed bentonite produced by industrial coal mines;

[0068] Nitrogen-fixing bacteria: Klebsiella and A. chroococcum, the ratio is 1:1, 0.2 parts;

[0069] Water retaining agent: 2 parts of polyacrylamide PAM soil water retaining agent;

[0070] method:

[0071] Take the raw materials in the formula, the corn, wheat, and sorghum used are rubbed, crushed and chopped into 3-5mm long, sprinkled with water to make the relative water content 50%-65%, and the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com