Preparation method of amorphous-nanocrystal improved terylene self-cleaning shielding fiber

An amorphous nanocrystalline, self-cleaning technology, applied in the chemical characteristics of fibers, rayon manufacturing, conductive/antistatic filament manufacturing, etc., can solve the problems of decreased shielding performance, loss of mechanical properties of materials, small size, etc. High performance, high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

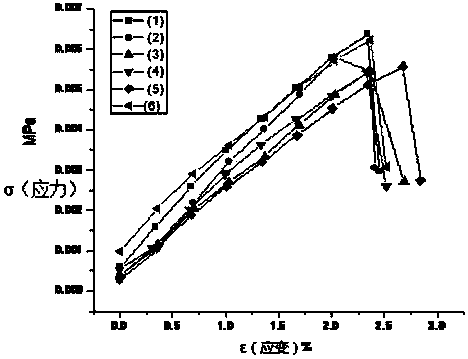

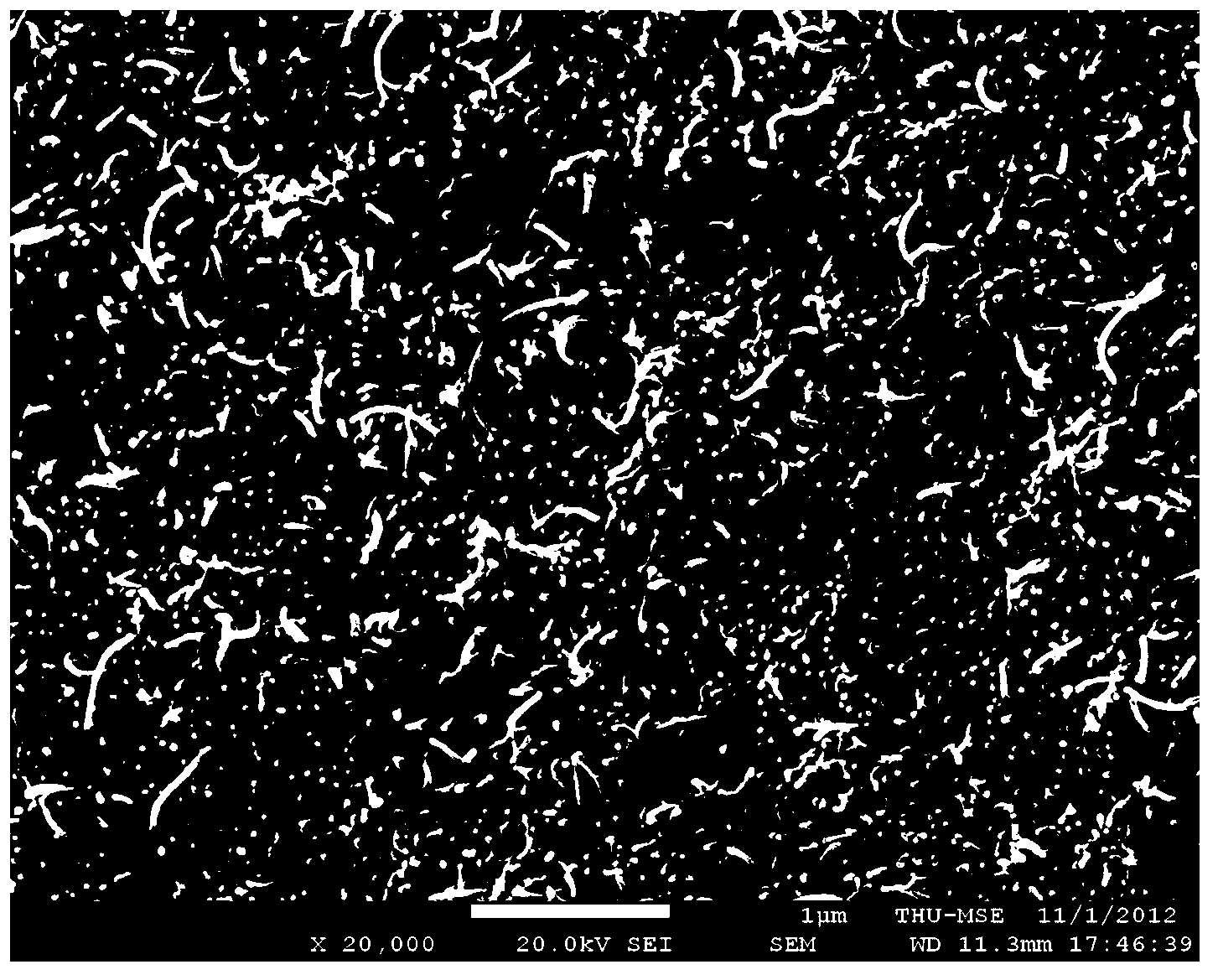

[0043] Example 1 (eg Figure 1-5 ):

[0044] (1) Selection of pre-treatment of raw materials

[0045] a) Adding untreated carbon nanotubes (CNTs) into HNO at a volume ratio of 3:1 3 (concentrated) with H 2 SO 4 (concentrated) mixed acid, ultrasonically oscillated at 80°C for 30 minutes, then heated in a water bath at 80°C for 30 minutes, filtered and washed until the pH was 7, and dried at 100°C for 4 h (hours) to obtain purified CNTs;

[0046] b) Treat purified CNTs, amorphous nano-FeCo powder (50nm), and nano-silver (50nm) with coupling agent KH560 (or titanate coupling agent, the effect is the same) with a mass fraction of 1% respectively, that is, the coupling agent Spray on the amorphous nanocrystalline nano functional powder, stir and mix, and then dry at 80°C for more than 4 hours;

[0047] c) Polyester Polyester is pre-crystallized at 140°C for 1 hour, and then dried at 160°C for more than 4 hours.

[0048] (2) Preparation of functional fibers

[0049] a) Dry po...

Embodiment 2

[0055] (1) Pretreatment of raw materials

[0056] With embodiment 1.

[0057] (2) Preparation of functional fibers

[0058] a) Same as Example 1.

[0059] b) Polyester polyester chips are mixed with the crushed and screened functional masterbatch at a mass ratio of 10:90, and after drying, a twin-screw extruder is used to make a spinning masterbatch.

[0060] c) Same as Example 1.

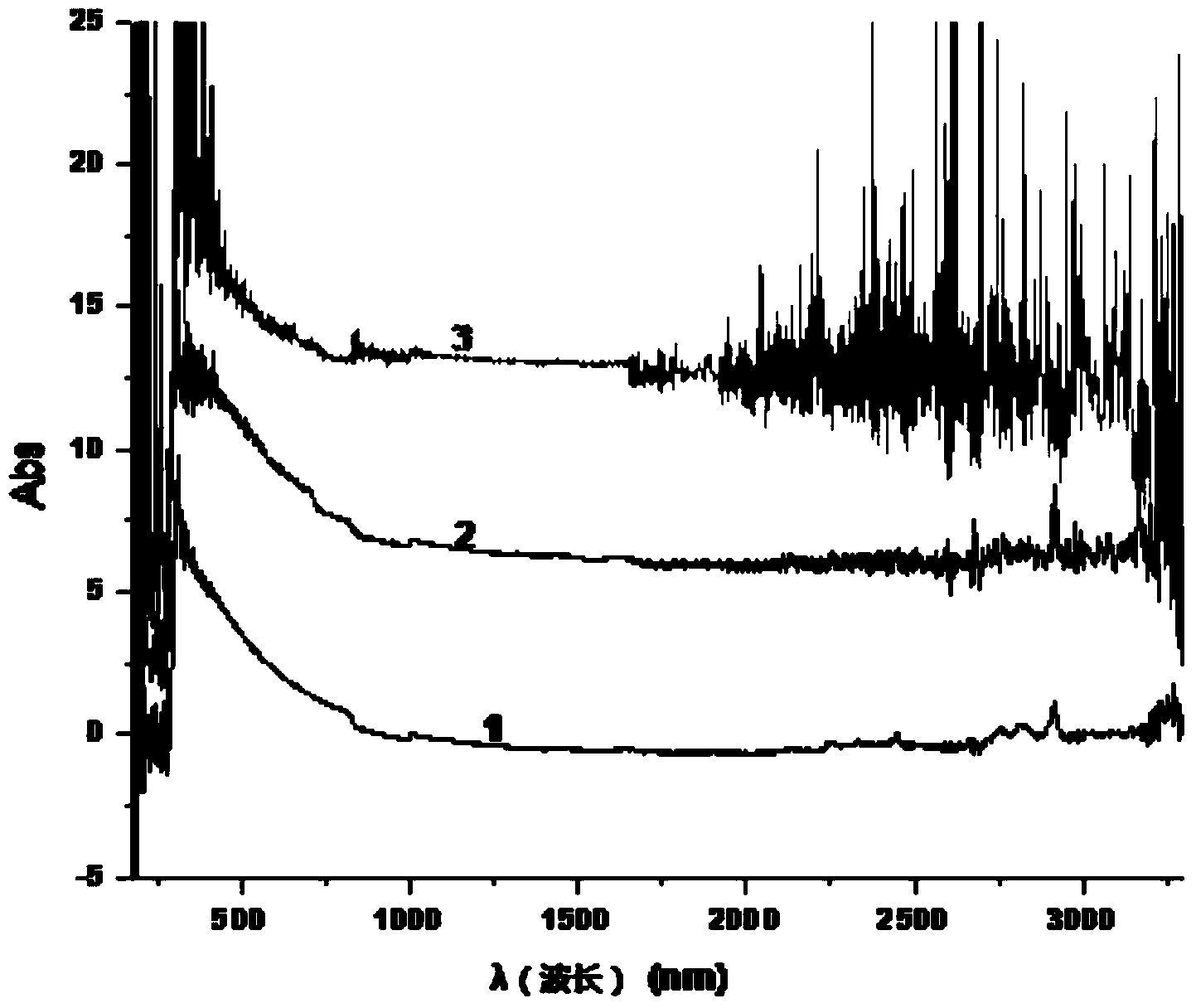

[0061] The obtained fineness is 132.69Dtex; the strength is 1.46% higher than that of the pure sample; the microwave shielding efficiency of the fiber fabric reaches 25dB; except for the strong absorption of 10Abs / mm in the ultraviolet to visible light region 300-800nm, the entire infrared region has 7.5Abs / mm absorb.

[0062]

Embodiment 3

[0064] (1) Pretreatment of raw materials

[0065] With embodiment 1.

[0066] (2) Preparation of functional fibers

[0067] a) Same as Example 1.

[0068] b) Polyester polyester chips are mixed with the pulverized and sieved functional masterbatch at a ratio of 30:70, and the others are the same as in Example 1.

[0069] c) Same as Example 1.

[0070] The obtained fineness is 54.50Dtex; the strength is 107% higher than that of the pure sample; the microwave shielding efficiency of fiber textiles reaches 15 dB; except for the strong absorption of 20Abs / mm in the ultraviolet to visible light region 300-800nm, the entire infrared region has 15Abs / mm absorb.

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com