Shale organic porosity detection method

A technology of organic porosity and detection method, applied in the fields of mining exploration and development, geology, and petroleum, can solve the problems of low success rate, inability to quantitatively evaluate porosity, and inability to evaluate the lack of interconnected pores in shale reservoirs. Inexpensive, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: as Figure 14 Described, a method for detecting organic porosity of shale, comprising the following steps;

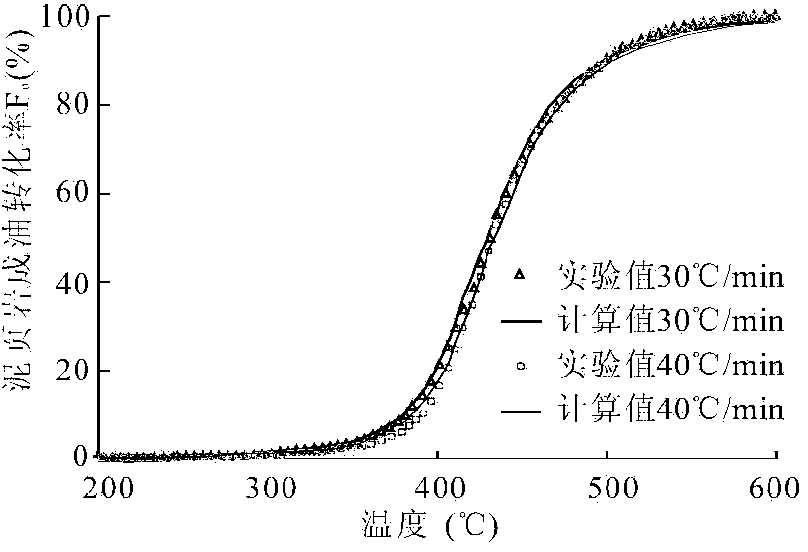

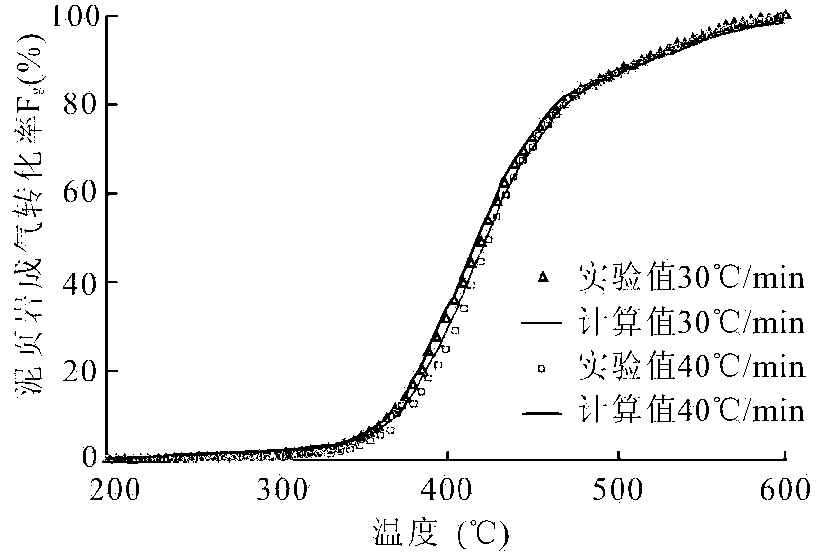

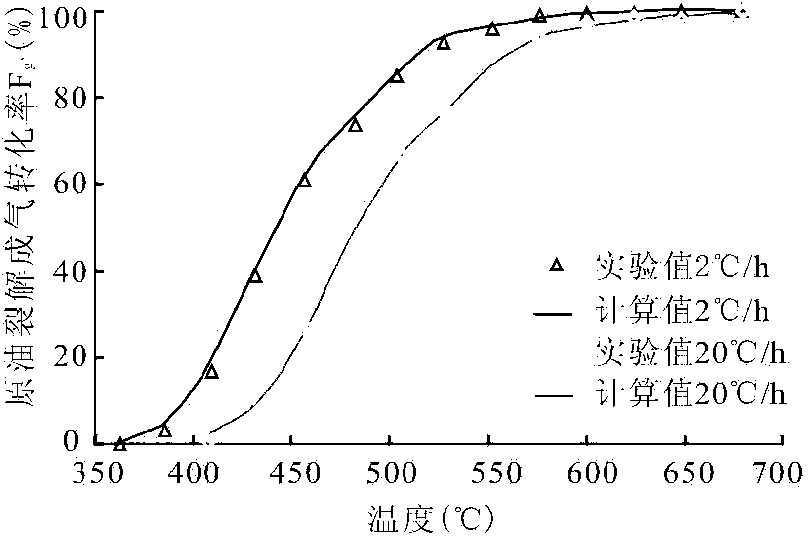

[0037]Step 1: Select low-maturity mud shale and crude oil samples similar to the source rock of the target layer, and use the Rock-Eval-II pyrolysis instrument to conduct high-temperature thermal simulation experiments. The mud shale samples were divided into two groups, starting from 200 °C, the mud shale samples were heated to 600 °C at the heating rate of 30 °C / min and 40 °C / min respectively; the crude oil samples were divided into two groups, starting from 350 °C At the beginning, the crude oil sample was heated to 700°C at a heating rate of 2°C / min and 20°C / min respectively; real-time recording of the oil production rate of the mud shale sample, the change of gas production rate with temperature (or time), and the cracking of the crude oil sample The gas production varies with temperature (or time), and the conversion rate F of kerogen to oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com