LED package

A technology of LED packaging and sealing components, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high color rendering index, narrow wavelength range of excitation light, and poor color purity, etc., to improve liquid crystal Display color gamut, improve image quality, and good light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

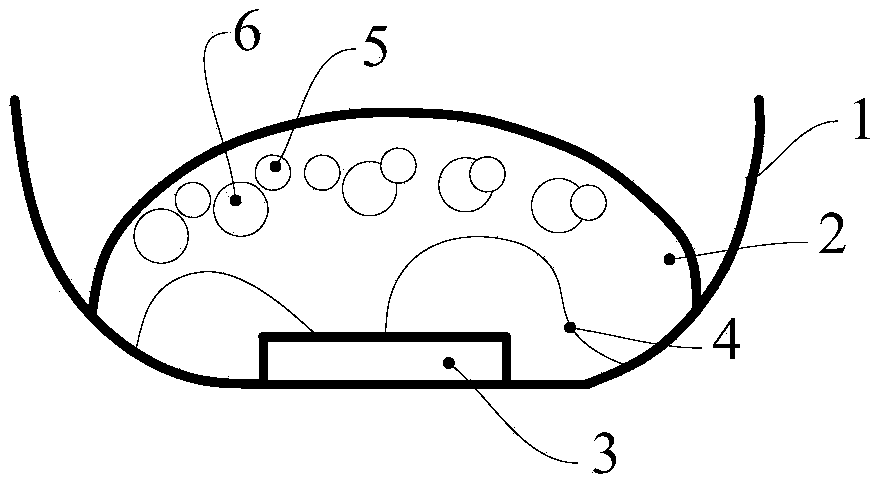

[0042] The present invention provides as attached figure 1 The LED package shown at least includes: a bracket 1 , a chip 3 , a bonding wire 4 , and a sealing component 2 . The bracket 1 is used to support the chip 3 and the bonding wire 4; the chip 3 is used to emit light that can effectively excite the phosphor powder 6 or the quantum dot 5; the bonding wire 4 is used to conduct the chip 3 and the bracket 1; Quantum dots 5 , located in the path of light emitted from the wafer 3 and having a lens shape, serve to wrap the wafer 3 and the holder 1 . The sealing component 2 is one layer, and phosphor powder 6 and / or quantum dots 5 are distributed in the carrier. The bracket 1 is made of iron plated with nickel and silver; the welding wire 4 is a gold wire; the chip 3 is a blue or ultraviolet chip, not limited to examples, as long as it can effectively excite the fluorescent powder 6 or the quantum dot 5 material; the quantum dot 5 It is CdSe / ZnS and CdSe / CdS / ZnS nanocrystalline...

Embodiment 2

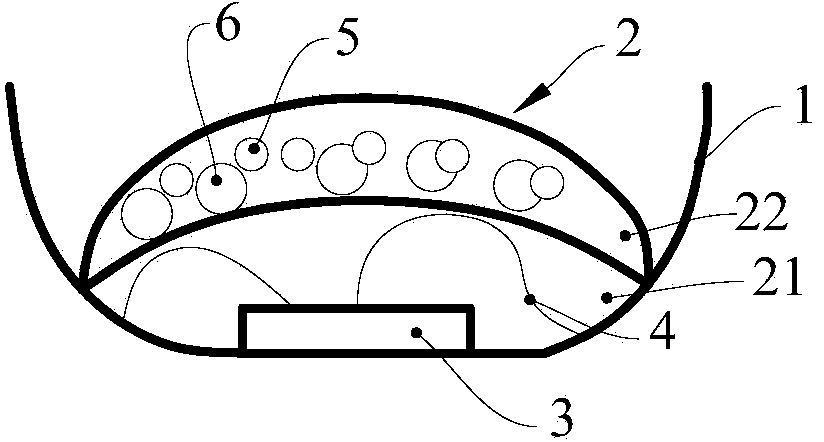

[0045] The present invention provides as attached figure 2 An LED package is shown.

[0046] The difference from the first embodiment is that the sealing component has two layers, which are the carrier 21 , phosphor or quantum dots mixed with the carrier 22 sequentially from the inside to the outside. The wafer 3 can be a blue or ultraviolet wafer, not limited to examples, as long as the phosphor 6 or the quantum dot 5 material can be effectively excited.

[0047] Encapsulation process: one kind of phosphor or quantum dot material or a mixture of excited materials is fully mixed with the carrier, the wafer is solidified, the carrier is placed in the LED bracket, and the colloid is cured for a long time, and the phosphor or quantum dot is One kind of material or a sufficient mixture with the carrier is dotted on the LED, baked, and the phosphor or quantum dot ratio is prepared according to the needs, and the required quantum dot LED is made. This LED packaging method is comp...

Embodiment 3

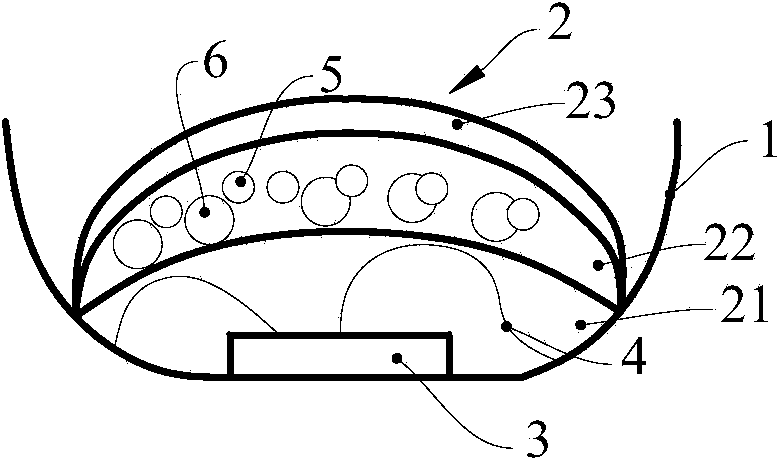

[0050] The present invention provides as attached image 3 An LED package is shown.

[0051] The difference from Embodiment 1 is that the sealing component has three layers, which are carrier 21, phosphor and / or quantum dot mixed with carrier 22, carrier or a layer of sealing colloid 23 that blocks air moisture from inside to outside. The wafer 3 can be a blue or ultraviolet wafer, not limited to examples, as long as it can effectively excite phosphors or quantum dot materials.

[0052] Encapsulation process: Mix one of the materials of phosphor or quantum dots or mixed with the excited material, fully mix with the carrier, solidify the wafer, put the carrier into the LED bracket, bake and cure the colloid, and put the phosphor and / or quantum dot One of the materials to be placed or mixed with the excited material is fully mixed with the carrier and placed on the LED, baked, and a carrier or a layer of sealing colloid that blocks air moisture is added to this layer, baked, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com