Device for producing composite particles and process for producing composite particles

A composite particle and manufacturing device technology, applied in the direction of granulating raw materials, chemical instruments and methods, and devices for coating liquid on the surface, etc., can solve problems such as unavoidable raw materials, pollution, and difficulty in increasing the output of target composite particles , to achieve the effect of improving work efficiency and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

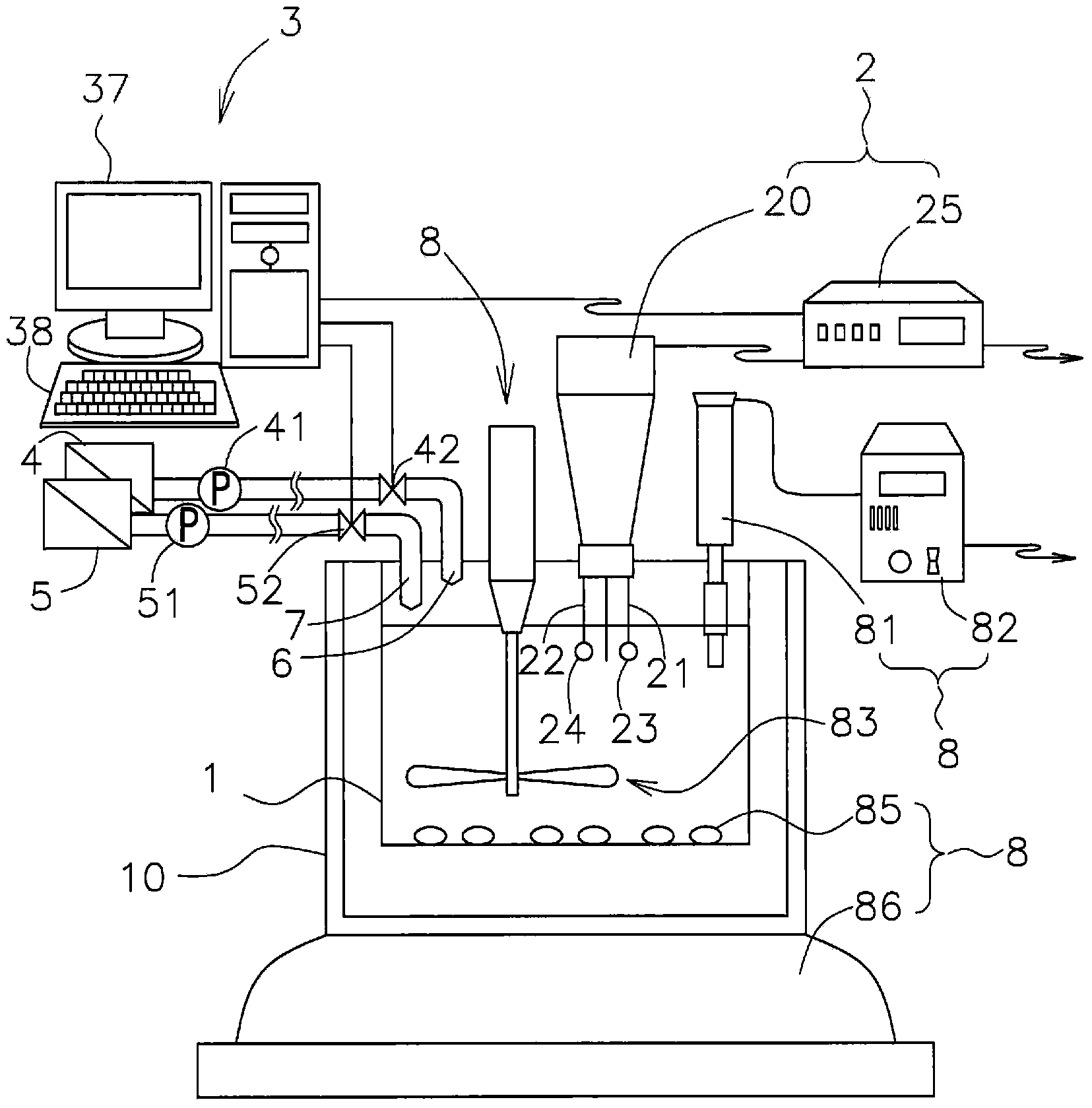

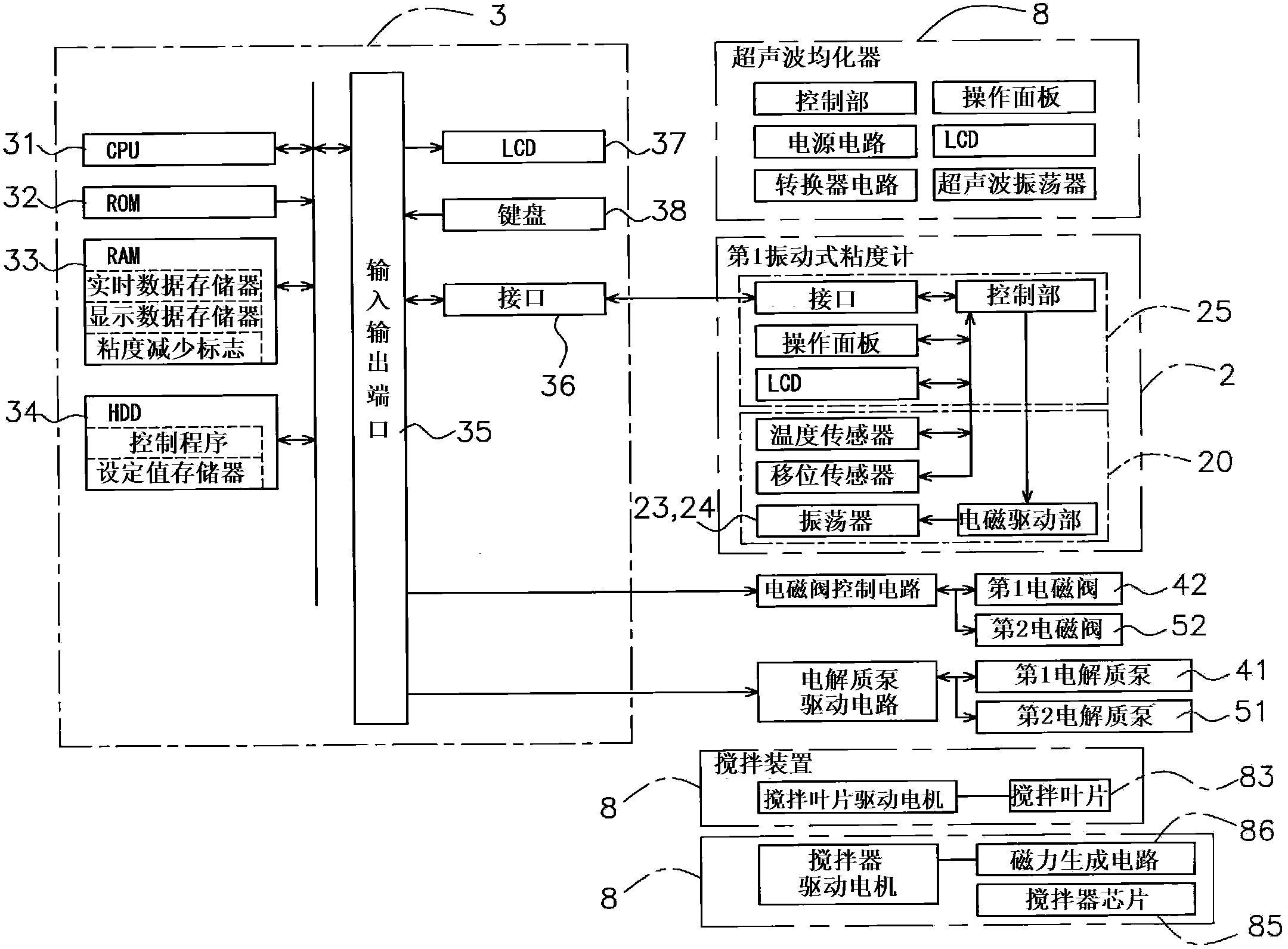

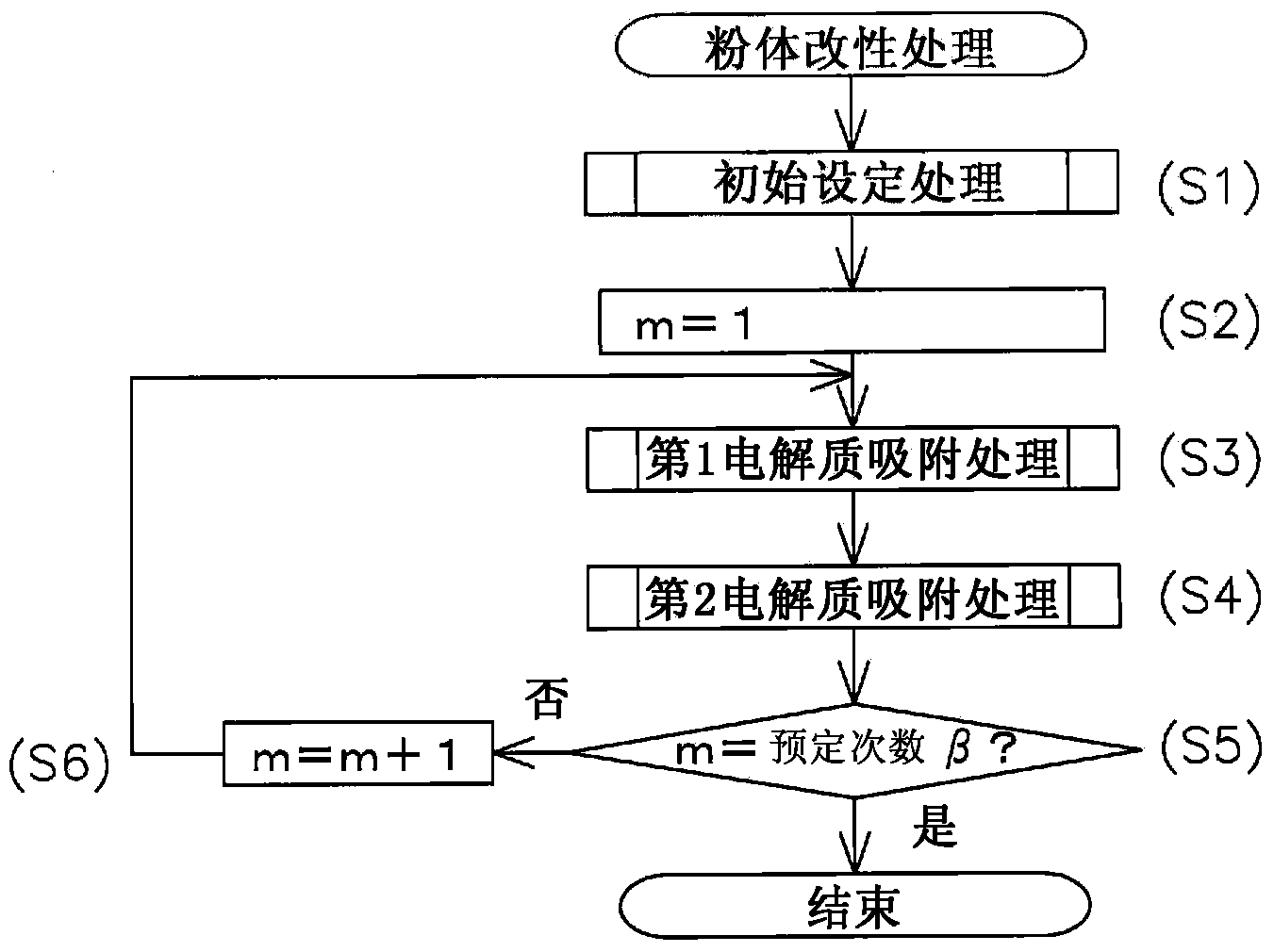

Method used

Image

Examples

experiment example

[0136] Next, an experiment was conducted on the relationship between the viscosity and the Zeta potential when the charge was adjusted by the above-mentioned charge adjustment method. The experimental method is that the aluminum oxide (α-Al 2 o 3 ) particles (diameter 100nm) liquid, while gradually adding polystyrene sulfonic acid (PSS) solution, the viscosity and Jieda potential were measured. Then, the viscosity and the Zeta potential were measured when a poly(diallylmethylammonium chloride) (PDDA) solution was gradually added to the liquid containing the polyanion-adsorbing particles produced as above.

[0137] Figure 14 represent the experimental results. As shown in the graph of the figure, when the polyanion (PSS) is gradually added to the particles, the Zeta potential changes from positive to negative, and the time when the value first becomes a value near the minimum value is closely related to the viscosity of the liquid containing the particles. Small values a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com