Production method for high-precision austenite seamless steel pipe

A seamless steel pipe and austenite technology, applied in the metallurgical field, can solve the problems of complex processing procedures, polluted environment by pickling, and high cost, and achieve the effects of simplifying procedures, reducing pollution, and shortening production cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

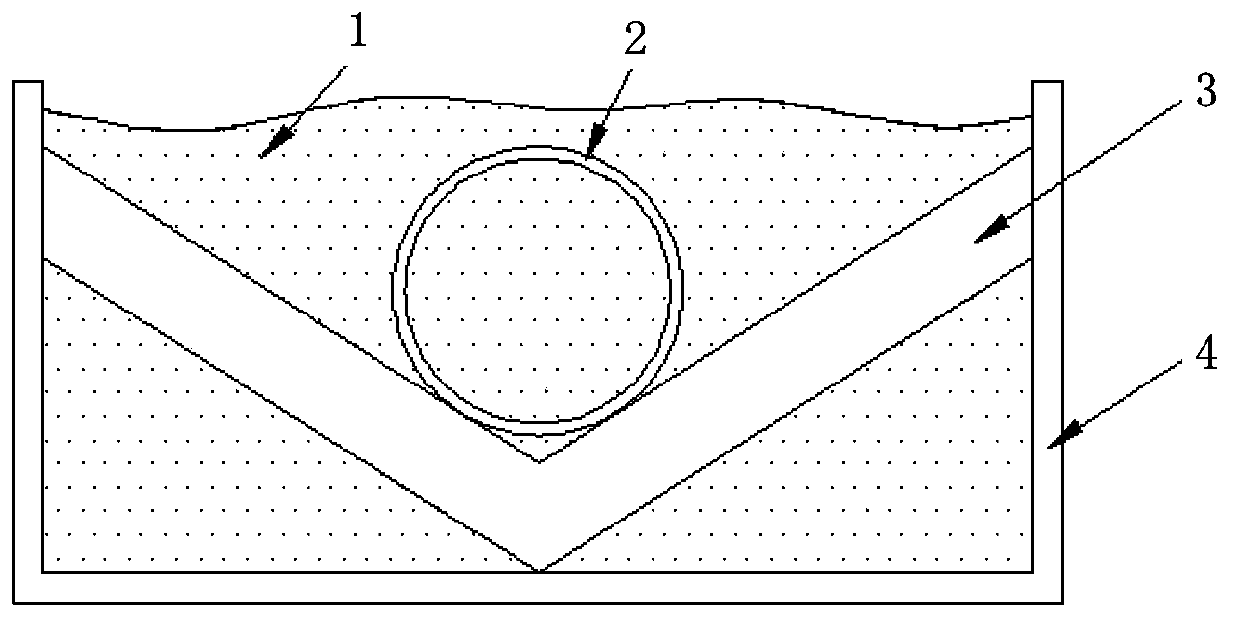

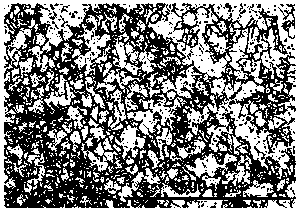

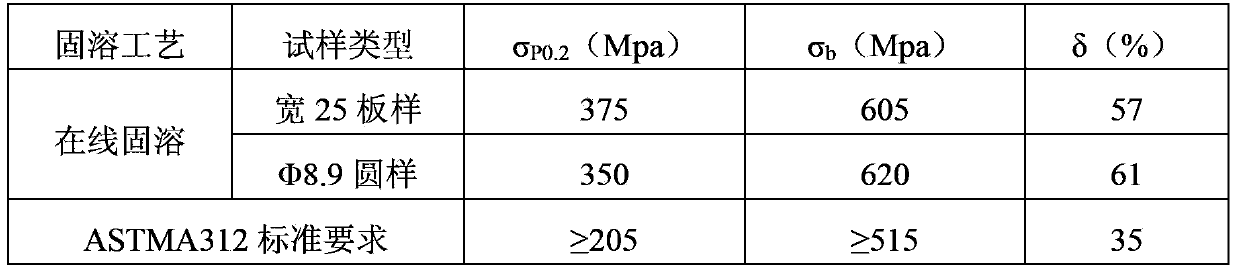

[0021] According to the ASTM SA-312 standard "Seamless and Welded Austenitic Stainless Steel Pipe" to produce TP347H austenitic stainless steel seamless pipe with a specification of Φ189×12.6. Specifically, the production process used is: electric furnace steelmaking→forging 220 billet→ring furnace heating→cross-rolling piercing→precision pipe rolling mill rolling tube→sizing→reheating solid solution→water cooling to room temperature→straightening→flaw detection , water pressure, inspection, packaging. Among them, the furnace temperature in the soaking section of the annular furnace is 1150 °C, the perforated plug is made of 20CrNi3WCoMo alloy steel, and the perforated hole is a Φ249×16.5 capillary tube; the roll distance of the rolling mill of the precision pipe mill is 222mm, the lead distance is 243mm, and the feed angle is 6° , the rolling angle is 13.5°, the exit speed is 0.35 m / s, hot-rolled into Φ245×13 waste pipes; after being sized into Φ189×12.6 finished steel pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com