Method for manufacturing GH4169 alloy aplitic plate blank

A GH4169, manufacturing method technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal processing equipment, etc., can solve the problems of increased forging fire times, unfavorable forming and quality standards, and difficult metals, so as to improve fatigue resistance, Ensure the effect of fineness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

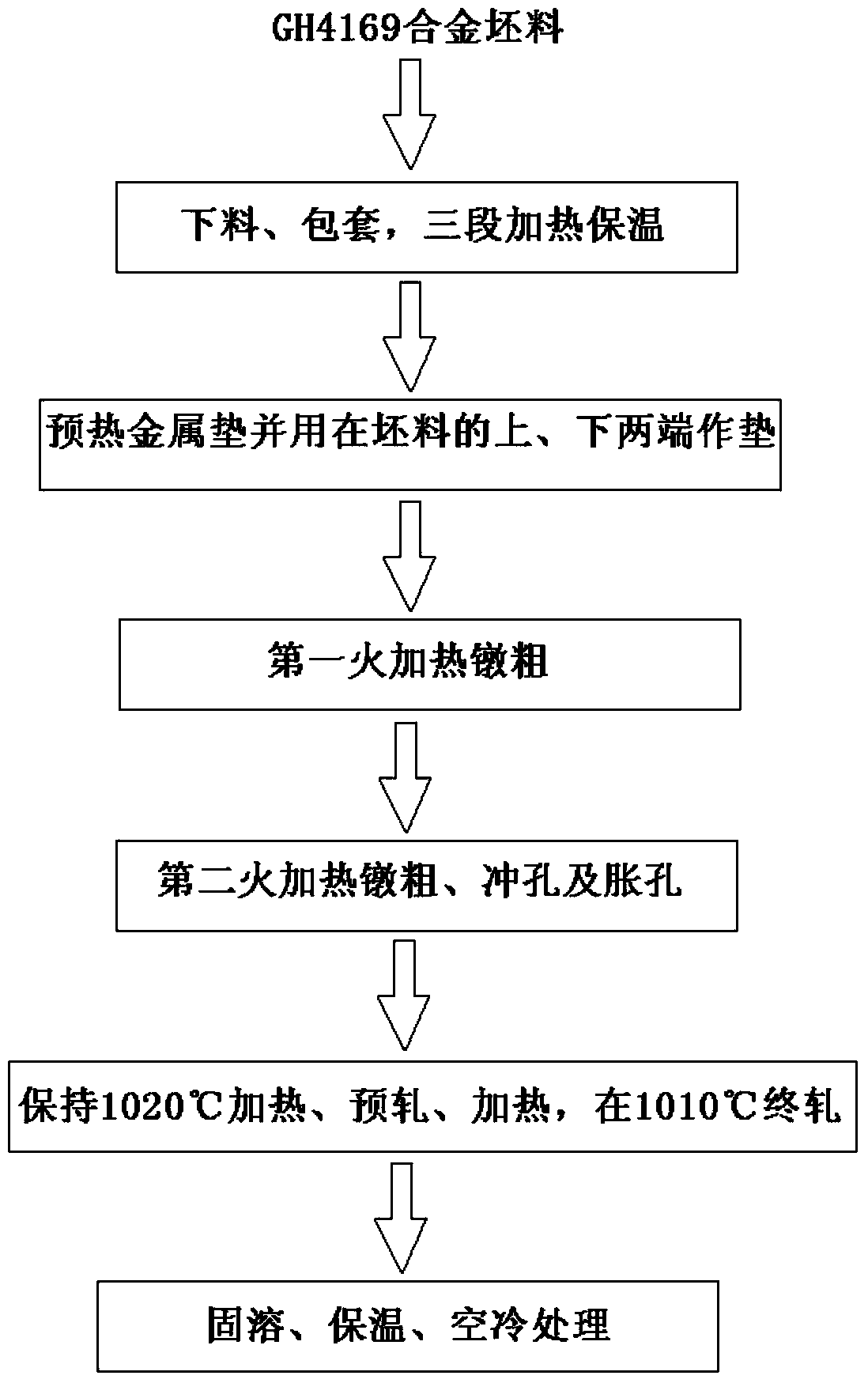

[0038] (1) Cutting, wrapping, three-stage heating and heat preservation:

[0039] Cover the billet with asbestos pads, and heat in three stages at 845°C (calculate the heating time as 6min / 10mm), 980°C (calculate the heating time as 8min / 10mm), and 1015°C (calculate the heating time as 6min / 10mm) heating the billet;

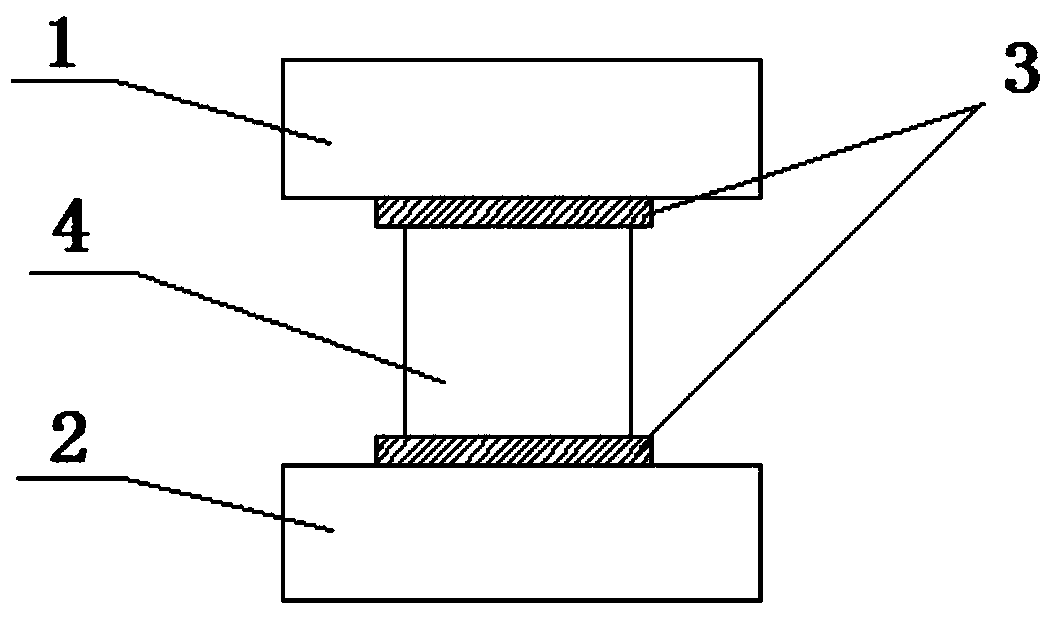

[0040] (2) Preheat the metal pad and use it as a pad at the upper and lower ends of the blank:

[0041] Preheat the metal pad with a thickness of 30mm at 295°C and use it as a pad at the upper and lower ends of the billet;

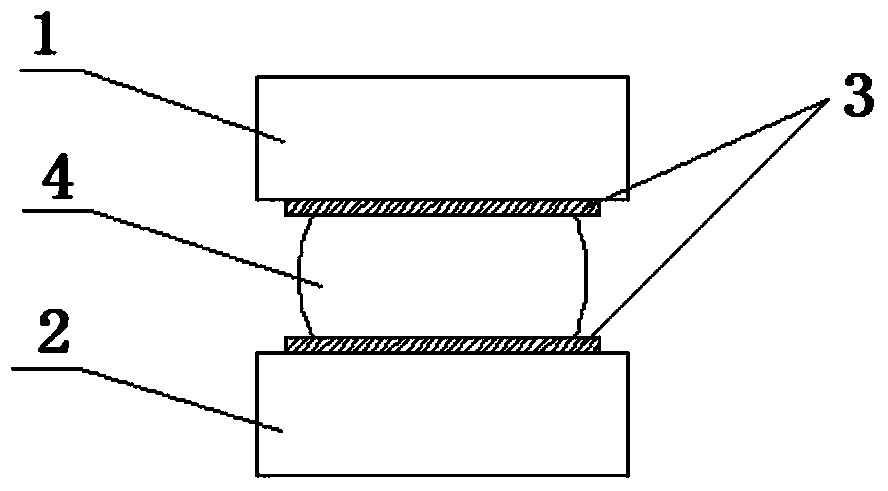

[0042] (3) The first fire heating upsetting:

[0043] Put the blank with the metal pad on a 2500T hydraulic press for upsetting, continue to deform at a constant speed by 20%, until the temperature measured by the optical thermometer is 1000°C, stay for a short period of 8 seconds, and then continue to deform at a constant speed by 30%, to the optical temperature The temperature measured by the thermometer is 960°C, and the final forging t...

Embodiment 2

[0051] (1) Cutting, wrapping, three-stage heating and heat preservation:

[0052] Cover the billet with asbestos pads, and heat in three stages at 855°C (calculate the heating time as 6min / 10mm), 990°C (calculate the heating time as 8min / 10mm), and 1025°C (calculate the heating time as 6min / 10mm) heating the billet;

[0053] (2) Preheat the metal pad and use it as a pad at the upper and lower ends of the blank:

[0054] Preheat the metal pad with a thickness of 30mm at 305°C and use it as a pad at the upper and lower ends of the billet;

[0055] (3) The first fire heating upsetting:

[0056] Put the blank with the metal pad on a 2500T hydraulic press for upsetting, and continue to deform 30% at a constant speed until the temperature measured by the optical thermometer is 1000°C. After a short stay of 12 seconds, continue to deform 40% at a constant speed until the temperature measured by the optical thermometer is 1000°C. The temperature measured by the thermometer is 960°C...

Embodiment 3

[0064] (1) Cutting, wrapping, three-stage heating and heat preservation:

[0065] Cover the billet with asbestos pads, and heat in three stages at 850°C (calculate the heating time as 6min / 10mm), 985°C (calculate the heating time as 8min / 10mm), and 1020°C (calculate the heating time as 6min / 10mm) heating the billet;

[0066] (2) Preheat the metal pad and use it as a pad at the upper and lower ends of the blank:

[0067] Preheat the metal pad with a thickness of 30mm at 300°C and use it as a pad at the upper and lower ends of the billet;

[0068] (3) The first fire heating upsetting:

[0069] Put the blank with the metal pad on a 2500T hydraulic press for upsetting, and continue to deform it by 25% at a constant speed until the temperature measured by the optical thermometer is 1000°C. The temperature measured by the thermometer is 960°C, and the final forging temperature is ≥930°C;

[0070] (4) The second heating upsetting, punching and expanding holes:

[0071] Return to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com