Casting polypropylene protection film pressure-sensitive adhesive, casting polypropylene protection film and their preparation methods

A technology of casting polypropylene and protective film, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, ester copolymer adhesives, etc., which can solve the problem of decreased cohesion of pressure-sensitive adhesives, poor high-temperature resistance of pressure-sensitive adhesives, and aggravated degumming problems and other problems, to achieve the effect of increasing molecular attraction, not easy to degumming, and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

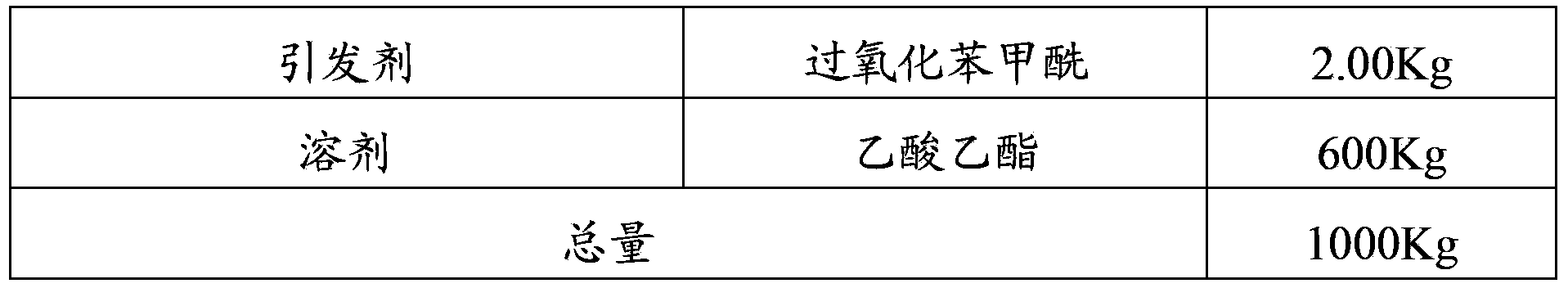

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of pressure-sensitive adhesive for cast polypropylene protective film

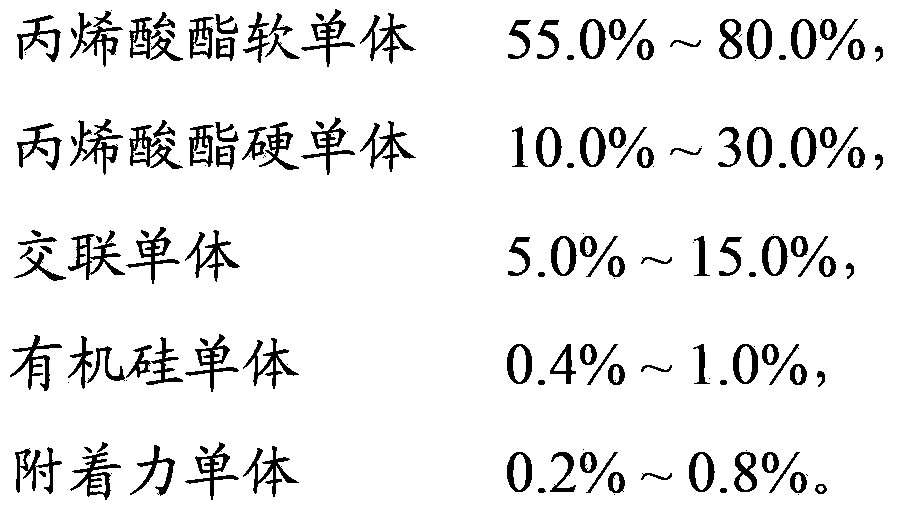

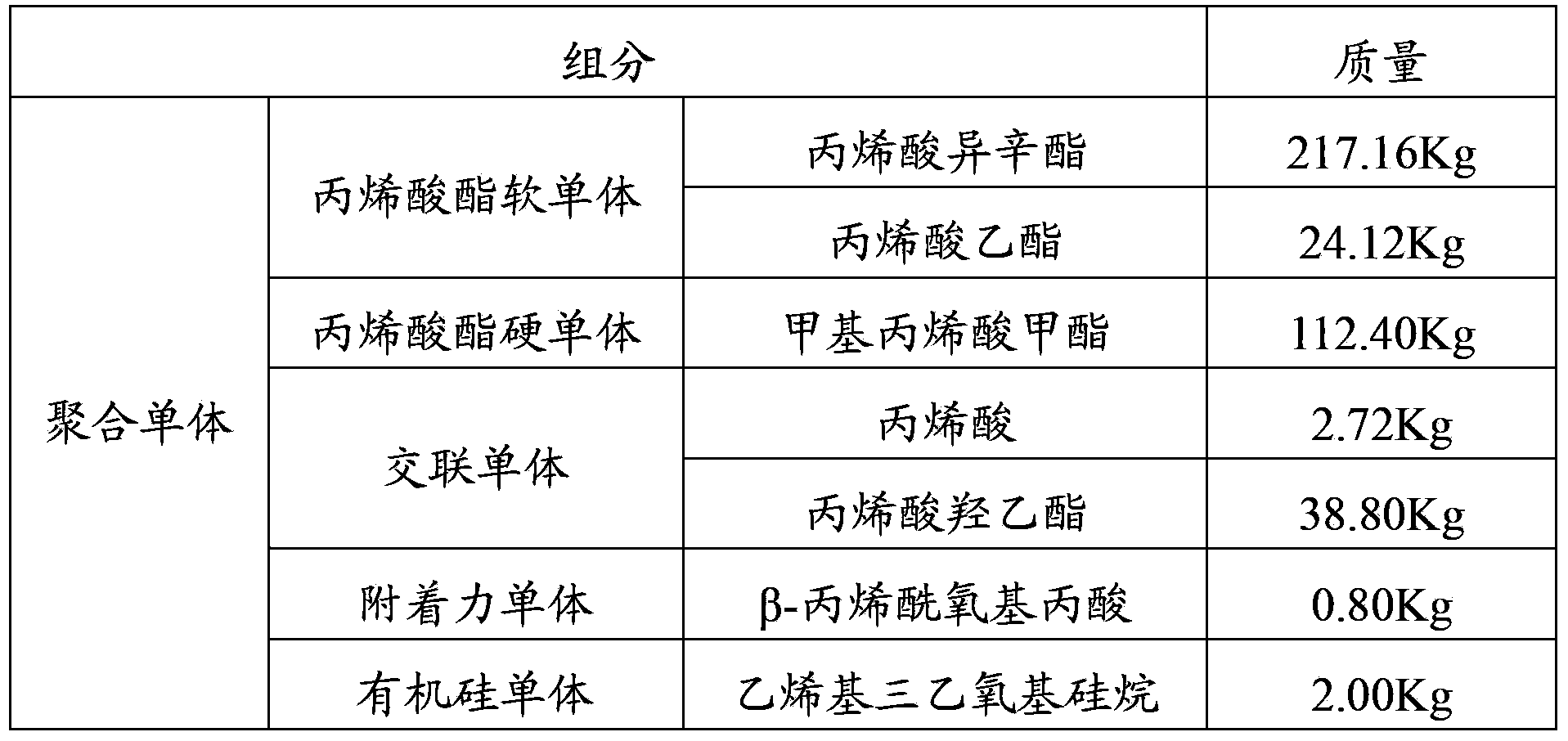

[0039] 1) Weigh each component according to the following formula:

[0040]

[0041]

[0042] 2) First feed nitrogen into the reactor, discharge the air in the reactor, then add 460Kg of ethyl acetate, and raise the temperature to 78°C-80°C;

[0043] 3) Add the polymerized monomer in step 1) into the feeding kettle, and stir evenly; then take 1.6Kg of benzoyl peroxide, dissolve it with 60.4Kg of ethyl acetate, add it to the feeding kettle, and stir evenly to obtain a mixed prepolymer Monomer 460Kg;

[0044] 4) Add 92Kg of mixed pre-polymerized monomers into the reactor, and keep it warm for 30-40 minutes at 78°C-80°C;

[0045] 5) Add the remaining 368Kg of mixed pre-polymerized monomers to the reaction kettle dropwise, and finish the dropwise addition in 3 to 3.5 hours, keep the temperature at 78°C to 80°C, and keep warm for 1 to 1.5 hours after the dropwise addition;

[0046...

Embodiment 2

[0056] 1. Preparation of pressure-sensitive adhesive for cast polypropylene protective film

[0057] 1) Weigh each component according to the following formula:

[0058]

[0059] 2) First feed nitrogen into the reactor, discharge the air in the reactor, then add 460Kg of ethyl acetate, and raise the temperature to 78°C-80°C;

[0060] 3) Add the polymerized monomer in step 1) into the feeding kettle, and stir evenly; then take 1.6Kg of benzoyl peroxide, dissolve it with 60.4Kg of ethyl acetate, add it to the feeding kettle, and stir evenly to obtain a mixed prepolymer Monomer 460Kg;

[0061] 4) Add 92Kg of mixed pre-polymerized monomers into the reactor, and keep it warm for 30-40 minutes at 78°C-80°C;

[0062] 5) Add the remaining 368Kg of mixed pre-polymerized monomers to the reaction kettle dropwise, and finish the dropwise addition in 3 to 3.5 hours, keep the temperature at 78°C to 80°C, and keep warm for 1 to 1.5 hours after the dropwise addition;

[0063] 6) Dissolv...

Embodiment 3

[0073] 1. Preparation of pressure-sensitive adhesive for cast polypropylene protective film

[0074] 1) Weigh each component according to the following formula:

[0075]

[0076] 2) First feed nitrogen into the reactor, discharge the air in the reactor, then add 460Kg of ethyl acetate, and raise the temperature to 78°C-80°C;

[0077] 3) Add the polymerized monomer in step 1) into the feeding kettle, and stir evenly; then take 1.6Kg of azobisisobutyronitrile, dissolve it with 60.4Kg of ethyl acetate, add it to the feeding kettle, and stir evenly to obtain a mixed pre- Polymer 460Kg;

[0078] 4) Add 92Kg of mixed pre-polymerized monomers into the reactor, and keep it warm for 30-40 minutes at 78°C-80°C;

[0079] 5) Add the remaining 368Kg of mixed pre-polymerized monomers to the reaction kettle dropwise, and finish the dropwise addition in 3 to 3.5 hours, keep the temperature at 78°C to 80°C, and keep warm for 1 to 1.5 hours after the dropwise addition;

[0080] 6) Dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com