Iron bath method high temperature gas waste heat and waste energy utilization and dry method dedusting technology

A dry dust removal and coal gas technology, which is applied in the direction of improving energy efficiency, process efficiency, waste heat treatment, etc., can solve the problems of difficult recovery and utilization of physical heat and chemical energy of coal gas, and achieve high-efficiency conversion and direct utilization, energy recovery High efficiency and good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

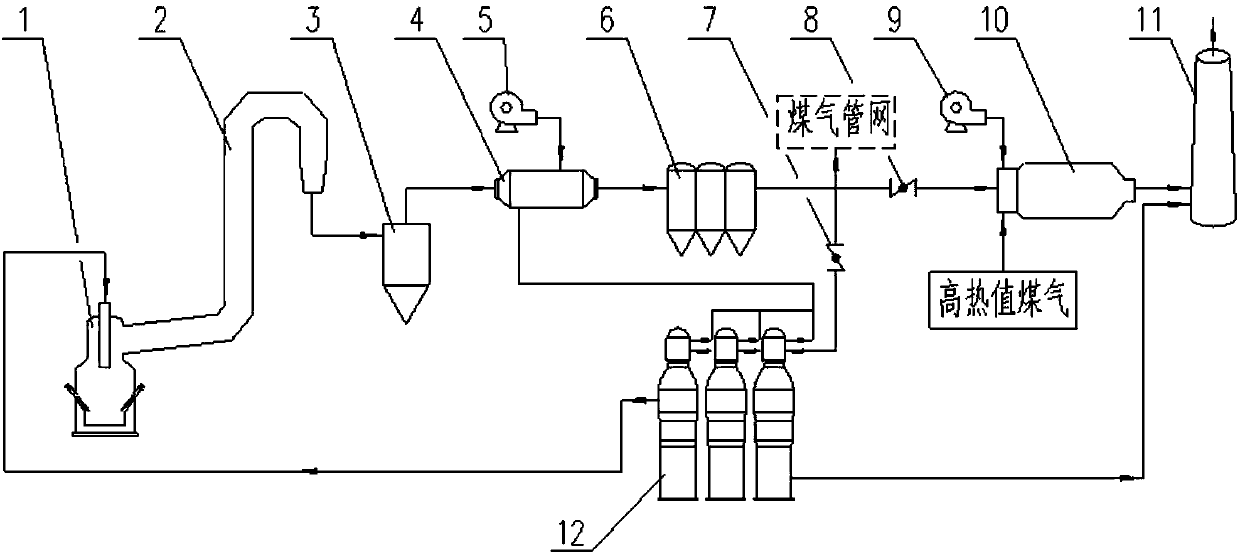

[0020] Such as figure 1 As shown, a new technology of high-efficiency utilization of waste heat and waste energy of high-temperature gas smelting reduction by iron bath method and dry dust removal technology, including water-cooled fume hood, cyclone dust collector, air-gas heat exchanger, bag filter, regulating valve, gas boiler, Hot blast stove, chimney, etc., the process steps include high-temperature gas at 1450°C and pressure of 0.08MPa from the iron bath furnace, with a flow rate of 2.2X10 5 N m 3 / h, first cooling down to 900°C through a water-cooled fume hood, and then entering the cyclone dust collector for coarse dust removal, the dust content of the gas is reduced from 70g / Nm 3 down to 12g / Nm 3 , and then through the air-gas heat exchanger to reduce the temperature of the gas to 180 °C, and at the same time heat the air to 400 °C, the cooled gas enters the bag filter for secondary dust removal, and the filtering wind speed (standard condition) is 0.8 m / min. Redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com