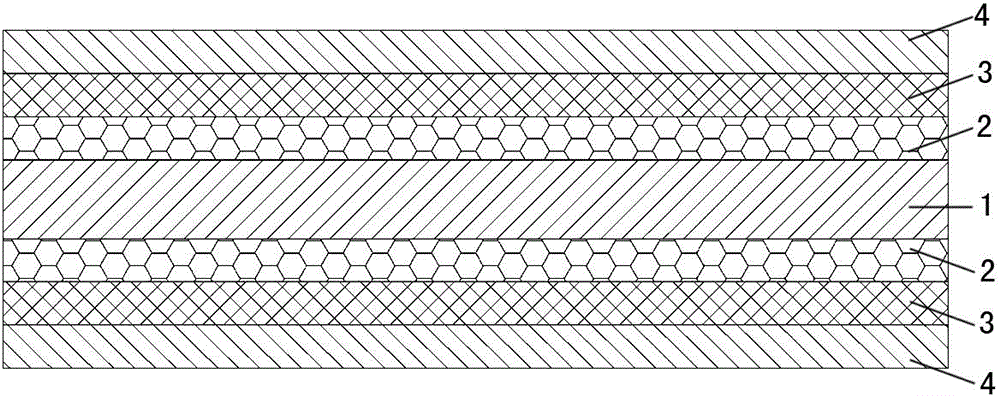

A kind of fiber-reinforced thermoplastic resin building formwork and its preparation method

A thermoplastic resin and fiber-reinforced technology, which is applied in the field preparation of building components, construction, building construction, etc., can solve the problems of high turnover times, cumbersome manufacturing process, and high difficulty, and achieve simple and feasible preparation process, durable surface Grinding, the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

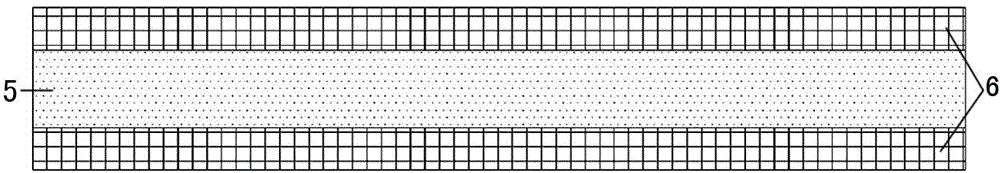

[0031] (1) The modified (PP fiber + PET fiber) and glass fiber are opened by a fiber opener, and then cross-laid, in which the polymer fiber: basalt fiber is 8:2, and the PP fiber: PET fiber is 3: 1. The aspect ratio of glass fiber is 3000. Sprinkle 5 parts of 500-mesh talcum powder through a powder spreader, and then perform double-sided needling after rolling and lamination to obtain a fiber-reinforced thermoplastic resin felt;

[0032] (2) Unwind 60g / m on the track of the compound machine from bottom to top 2 Modified PE film, sprinkled with glass fiber, unwinding 60g / m 2 The modified PE film is hot-compressed at 160°C and 2MPa, cooled and cut to obtain a single-layer reinforced fiber mat, and then 12 layers of reinforced fiber mats are sequentially unwound on the track of the compound machine from bottom to top. The transmission speed is 10 m / min, and the composite fiber reinforced felt is obtained;

[0033] (3) The fiber-reinforced thermoplastic resin felt is first pas...

Embodiment 2

[0035] (1) After the modified PP fiber and basalt fiber are opened by a fiber opener, they are then cross-laid. The polymer fiber: basalt fiber is 6:4, and the aspect ratio of the basalt fiber is 1500. Sprinkle 10 parts of 200-mesh calcium carbonate through a powder spreader, and then perform double-sided needling after rolling and lamination to obtain a fiber-reinforced thermoplastic resin felt;

[0036] (2) Unwind 120 g / m on the crawler of the compound machine from bottom to top 2 Modified PP film, sprinkled with basalt fiber, unwinding 120g / m 2 The modified PP film is hot-compressed at 190°C and 1MPa, cooled and cut to obtain a single-layer reinforced fiber mat, and then 8 layers of reinforced fiber mat are sequentially unwound on the track of the compound machine from bottom to top. The transmission speed is 6m / min, and the composite fiber reinforced felt is obtained;

[0037] (3) The fiber-reinforced thermoplastic resin felt is first passed through a contact heating dev...

Embodiment 3

[0039] (1) After the modified (PP fiber + PA fiber) and glass fiber are opened by a fiber opener, they are then cross-laid, where the polymer fiber: glass fiber is 5:5, and the PP fiber: PA fiber is 4: 1. The aspect ratio of glass fiber is 500. Sprinkle 15 parts of 80-mesh high-density polyethylene rubber powder through a powder spreader, and then perform double-sided needling after rolling and lamination to obtain a fiber-reinforced thermoplastic resin felt;

[0040] (2) Unwind 200g / m on the track of the compound machine from bottom to top 2 Modified PP / PET blend film, sprinkled with glass fiber, unwinding 200g / m 2 The modified PP / PET blend film was hot-compressed at 210°C and 0.3 MPa, cooled and cut to obtain a single-layer reinforced fiber mat, and then four layers were unwound from bottom to top on the track of the compound machine. Reinforced fiber felt, transmission speed is 2 m / min, get composite fiber reinforced felt;

[0041] (3) The fiber-reinforced thermoplast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com