Intelligent long scale distance strain sensor and manufacturing method thereof

A technology of a strain sensor and a manufacturing method, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of affecting measurement accuracy, inability to perform positioning compensation, insufficient durability, etc., and improve measurement performance and monitoring accuracy. , The effect of improving measurement performance and monitoring accuracy, improving anti-aging performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

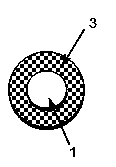

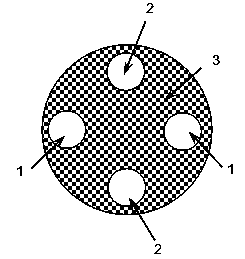

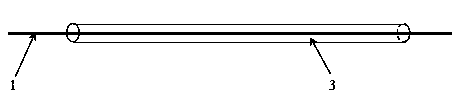

[0036] like Figure 1 to Figure 8 As shown, an intelligent long gauge strain sensor includes a sensing core 4 and an intelligent module 7. One end of the sensing core 4 is connected to the intelligent module 7; The reinforcing layer 3 is composed of the reinforcing layer 3, the outer periphery of the reinforcing layer 3 is arranged with a sleeve 12, the outer periphery of the sleeve 12 is arranged with an encapsulation layer 6, and the two ends of the encapsulation layer 6 are respectively provided with encapsulation anchor points 5; wherein, the reinforcing layer and the encapsulation layer can be fiber-reinforced Made of composite material or high-performance polymer material; the intelligent module 7 is composed of a data acquisition chip and a wireless sensor.

[0037] like figure 2 , Figure 4 , Image 6 As shown, the resistance wire of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com