Detection system of photoacoustic spectrometry gas in fiber laser device cavity

A technology of gas detection system and fiber laser, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low sensitivity, loss of light energy, and improvement of detection sensitivity limit, etc., to achieve improved detection signal strength, low cost, and improved detection The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

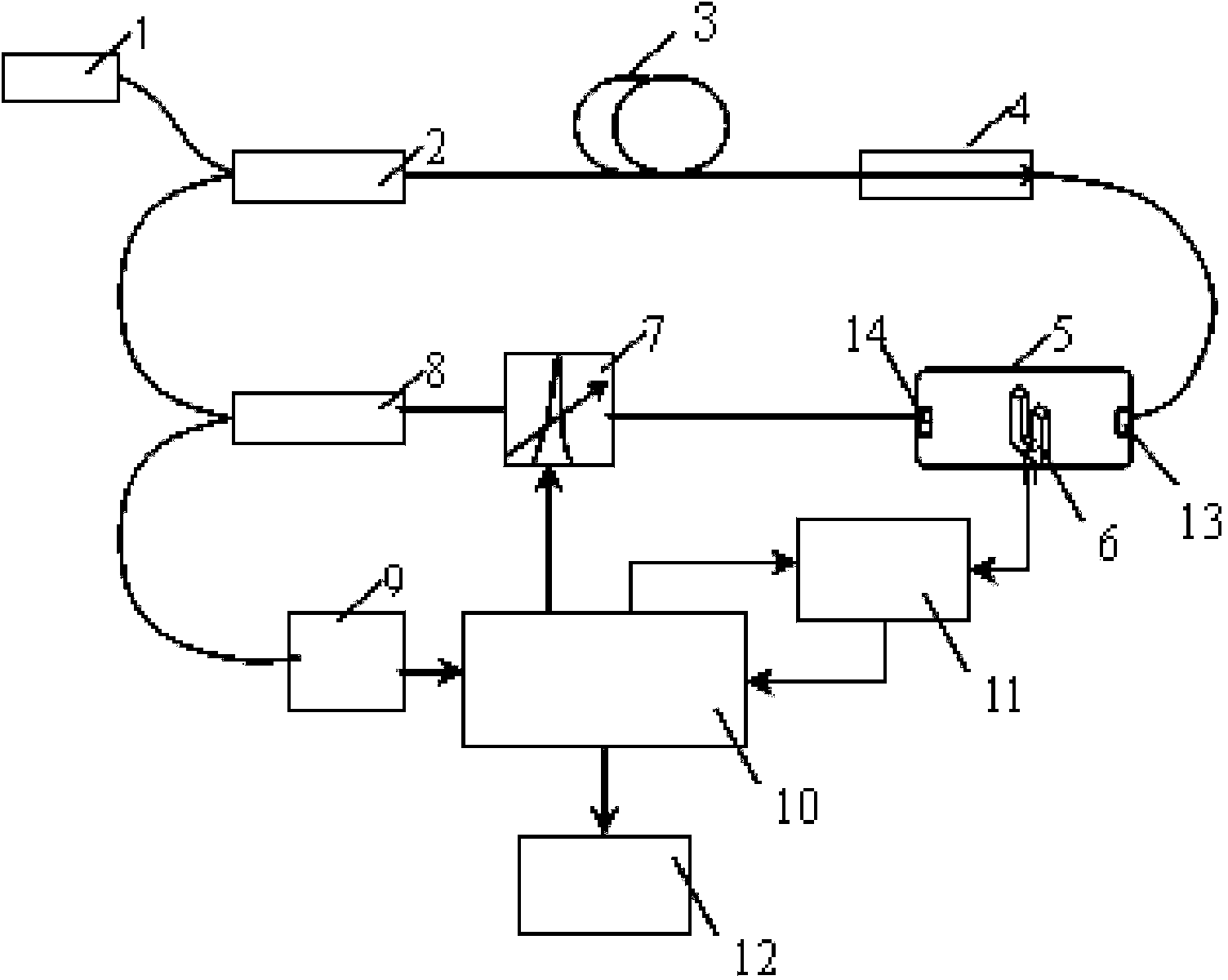

[0024] Such as figure 1 As shown, a fiber laser intracavity photoacoustic gas detection system includes a pump light source 1, a wavelength division multiplexer 2, a rare earth doped fiber 3, an optical isolator 4, a gas chamber 5, an input coupling mirror 13, an output Coupling mirror 14, quartz tuning fork 6, tunable filter 7, fiber coupler 8, photodetector 9, data acquisition card 10, lock-in amplifier 11, computer 12, it is characterized in that the output terminal of pumping light source 1 is connected with WDM The device 2 corresponds to the input end, the compound end of the wavelength division multiplexer 2 is connected to one end of the rare earth doped fiber 3, the other end of the rare earth doped fiber 3 is connected to the input end of the optical isolator 4, and the output end of the optical isolator 4 is connected to the gas chamber 5 The input coupling mirror 13 placed inside, the optical axes of the input coupling mirror 13 and the output coupling mirror 14 ar...

Embodiment 2

[0031] Same as Embodiment 1, except that the rare earth-doped fiber 3 is an ytterbium-doped fiber.

Embodiment 3

[0033] Same as Embodiment 1, except that the rare earth-doped fiber 3 is a thulium-doped fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com