A mems fork beam capacitive accelerometer and its manufacturing method

A technology of accelerometer and manufacturing method, applied in the direction of measuring acceleration, velocity/acceleration/impact measurement, manufacturing microstructure devices, etc., can solve cross interference between working mode and adjacent mode, accelerometer deviation from working mode, process Highly difficult problems, to achieve the effect of ensuring quality, improving device integrity, and suppressing cross-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

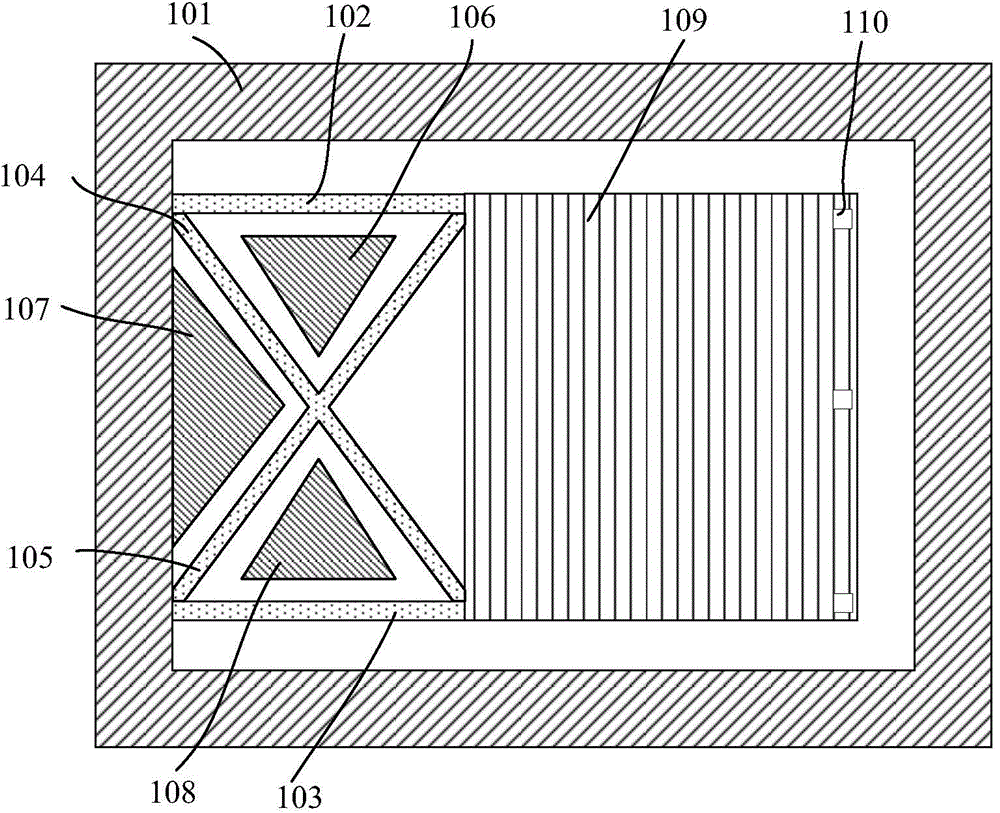

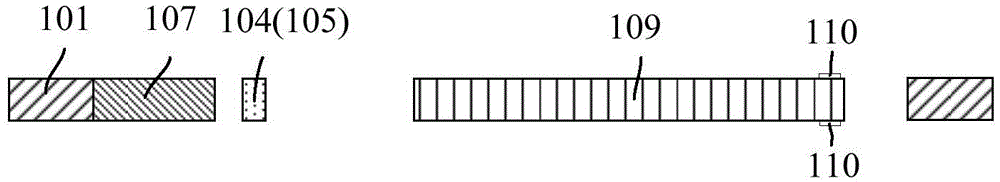

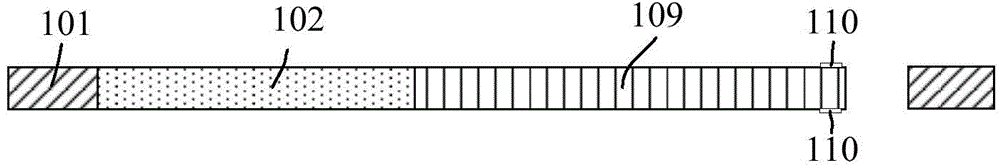

[0042] As shown in Figure 1, it is the schematic diagram of the silicon layer structure of the MEMS fork beam capacitive accelerometer of the present invention, wherein Figure 1A , 1B, 1C are top view, sectional view 1 (cut along fork beam 104 or 105) and sectional view 2 (cut along cantilever beam 102), silicon layer 1 includes rectangular outer frame 101, cantilever beams 102 and 103, fork beam 104 and 105 , silicon islands 106 and 108 , silicon layer electrode lead-out area 107 , mass block 109 , and anti-collision block 110 . Two cantilever beams 102, 103 are formed inside the rectangular outer frame 101, fork beams 104, 105 are arranged in the middle of the two cantilever beams 102, 103, and the two fork beams 104, 105 are located between the two cantilever beams 102, 103, mass Block 109, the diagonal position of the rectangular frame sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com